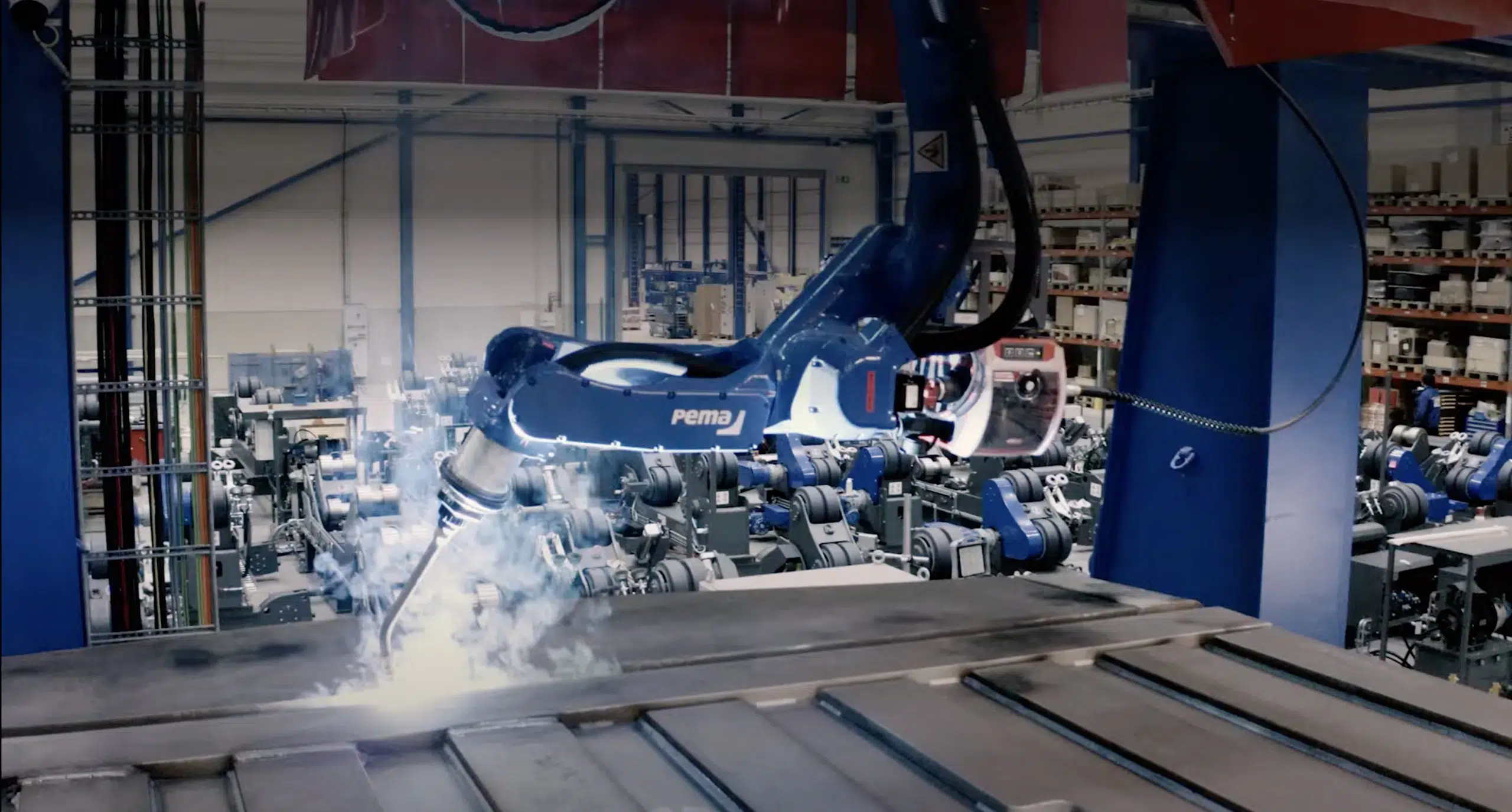

Mission impossible accomplished: Fully automated submerged arc multi-pass welding for heavy wall thicknesses.

Every great innovation was once considered impossible. Today, at Pemamek, we are proud to announce that we have entered the final development stage of the fully automated submerged arc multi-pass welding concept for heavy wall thicknesses. This groundbreaking technology marks another milestone in our 54-year journey of accelerating productivity in the global heavy manufacturing industry.

”With our current, well-proven scanner technology, the level of automation is 90%. This next step is made possible through deep expertise and persistent development,” says Mr. Torben Blaaholm, Director of the Wind energy segment at Pemamek.

The technology concept

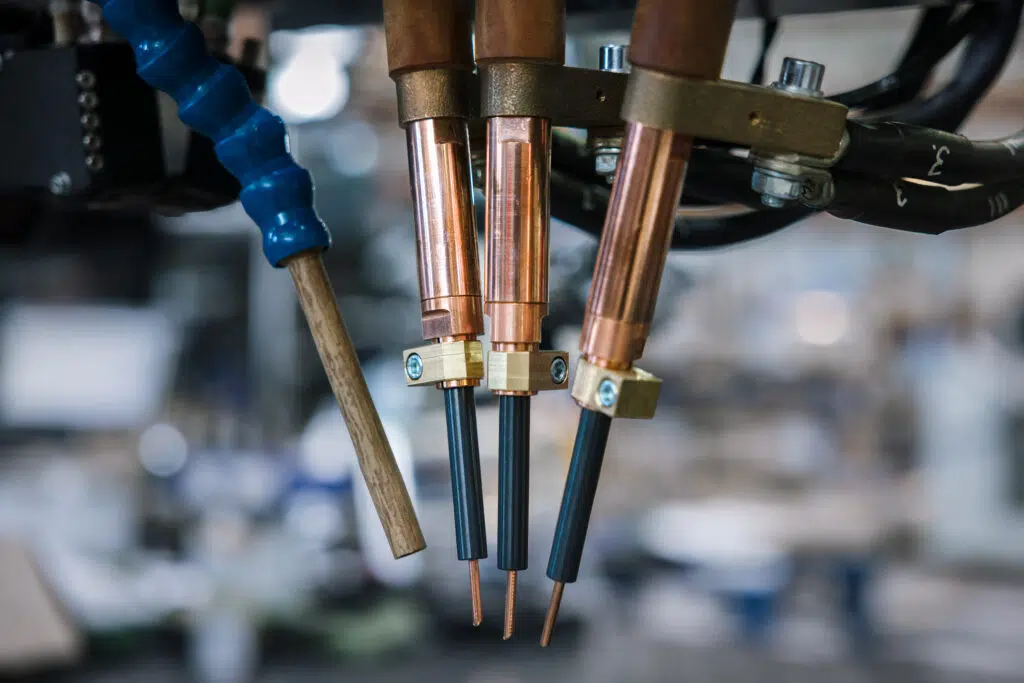

The innovation combines multiple submerged arc welding heads equipped with triple wire long-stick-out. The fully automated multi-pass welding process will offer unseen production efficiency, predictability, and stability.

The solution will be operated with the industry-leading, in-house developed PEMA software. This combination will be the next major step in welding automation of heavy wall thicknesses, such as those used in monopile manufacturing.

The commercialization horizon

The concept has reached the final development stage at Pemamek. Following a thorough factory testing process, the first commercial contracts are planned for 2026–2027.

For more information and confidential discussions:

Torben Blaaholm

+45 29 89 74 28

sale@docprofitmachine.com