Pemamek

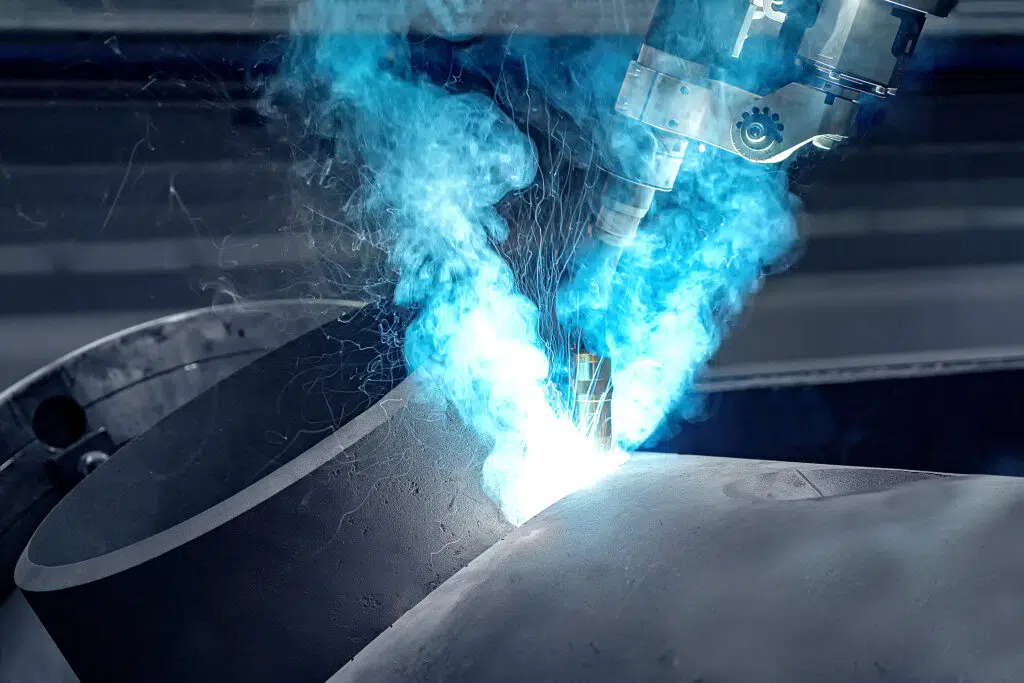

Robotic welding systems for constant welding quality and increased production capacity.

The times are changing, and we all need to rethink manufacturing. PEMA robotic welding solutions help you take your manufacturing into the 2020 century.

Robotic welding systems provide an effective solution to challenges, such as a shortage of skilled welders and increasing demands for productivity and efficiency. A well-designed robotic welding cell enhances safety, improves quality, and boosts competitiveness.

Turn-key robotic welding systems, easy programming, and one operator responsible for the show.

By partnering with Pemamek, you receive a complete, turnkey package tailored to your needs. From robotic welders to robotic welding positioners, all solutions are custom-made to maximize efficiency and fit your production requirements.

Robotic welding

PEMA Skytrack is a compact robot welding solution designed for workshops that look to increase their production on flexibility and scalability.

Robotic welding

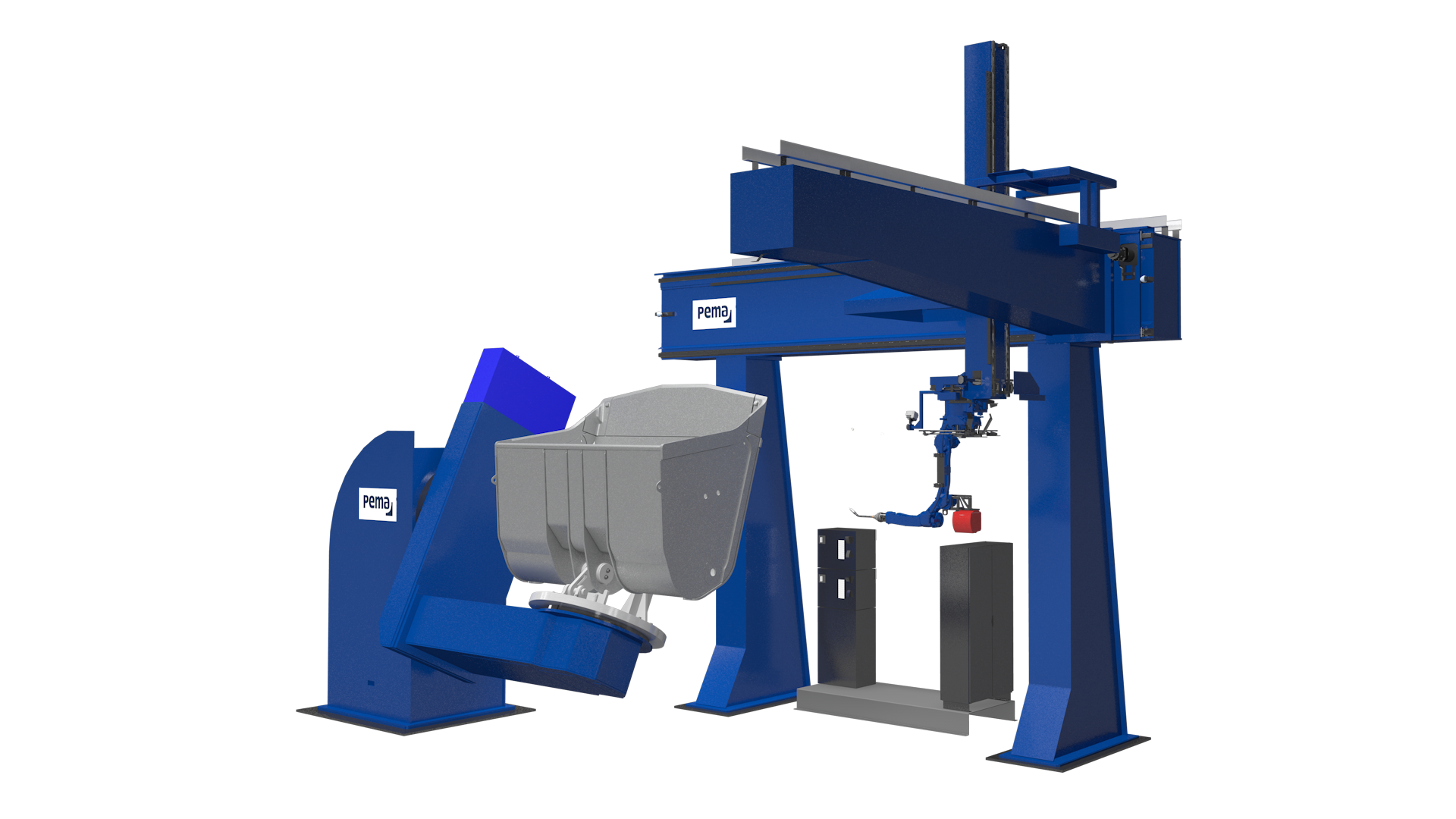

Typically, a PEMA robotic welding system consists of a workpiece handling solution and a gantry (half portal) with one to three linear axes.

robotic welding

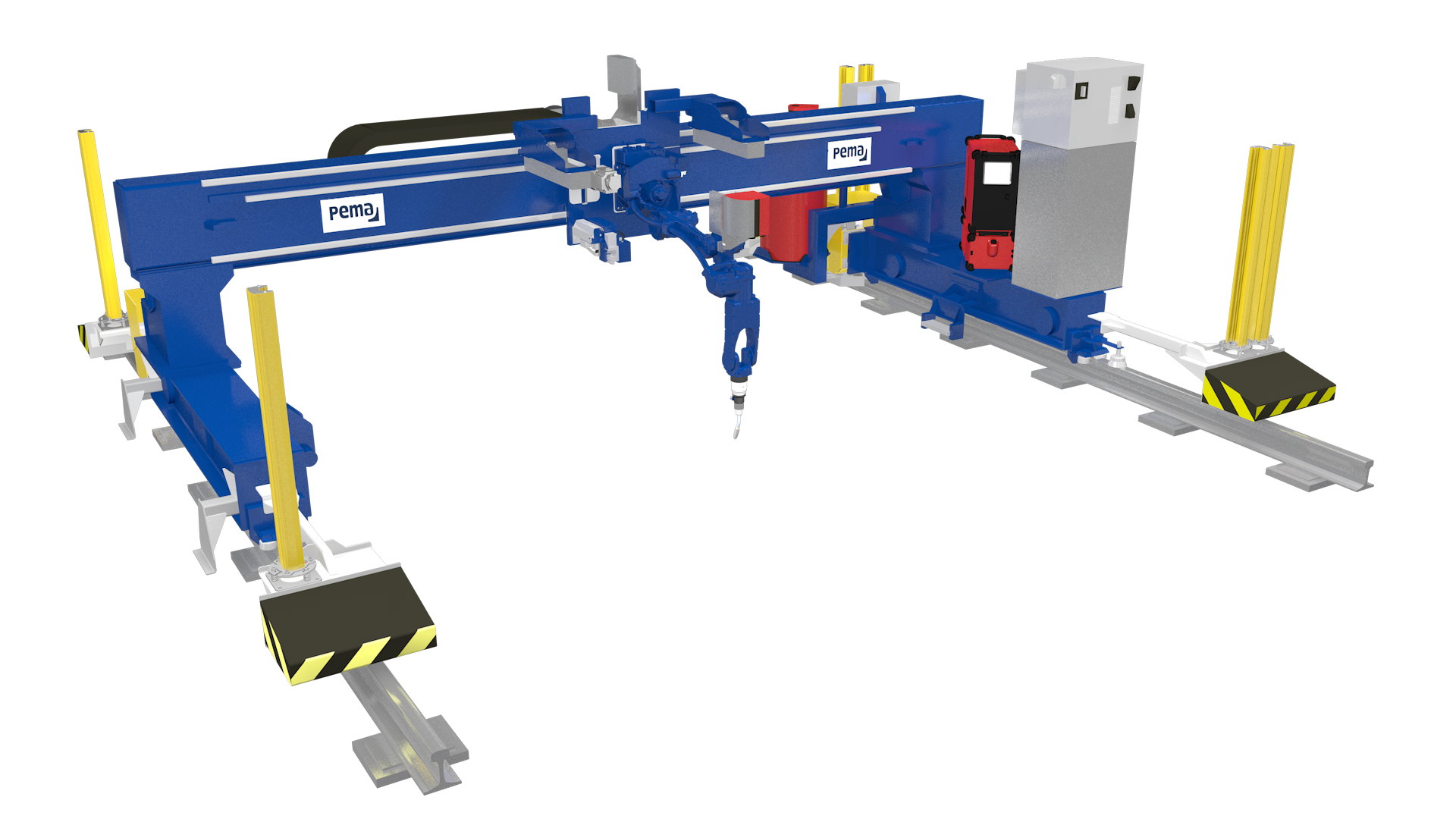

Pemamek provides customized solutions for its customers. Here the floor track length is not limited, height is adjustable, X-axis can vary from 3,3m to 4,1m.

Robotic welding

PEMA VRWP-C is a compact robot welding solution for micro-panel production. PEMA VRWP-C is fast to install with minimum civil work, and it can replace up to four manual welders.

robotic welding

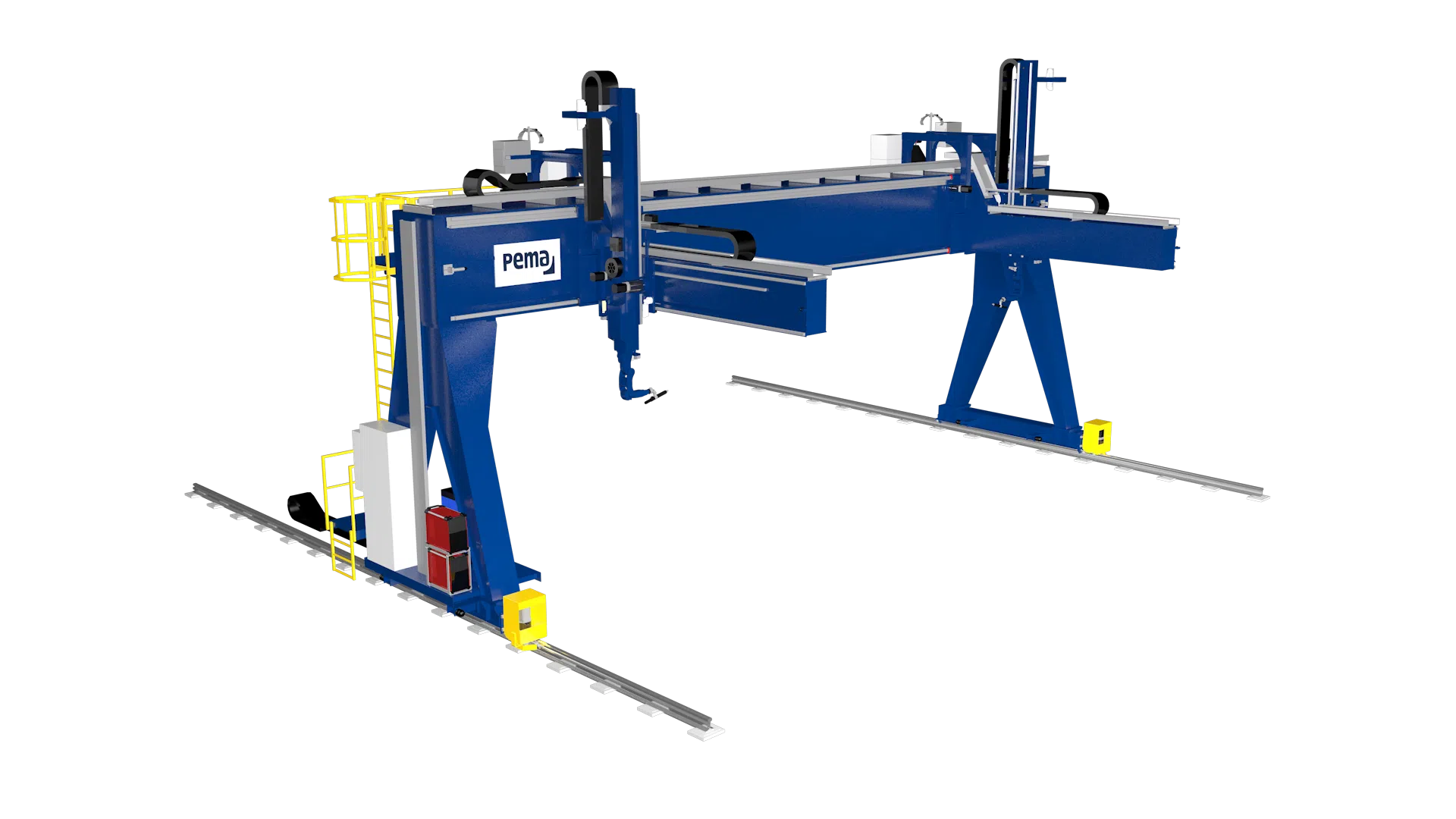

PEMA Robotic Welding Portal, one portal up to 4 robots, with full capability of robotic welding is fast to install, the working area can be expanded, and dimensions engineered according to the product to be welded.

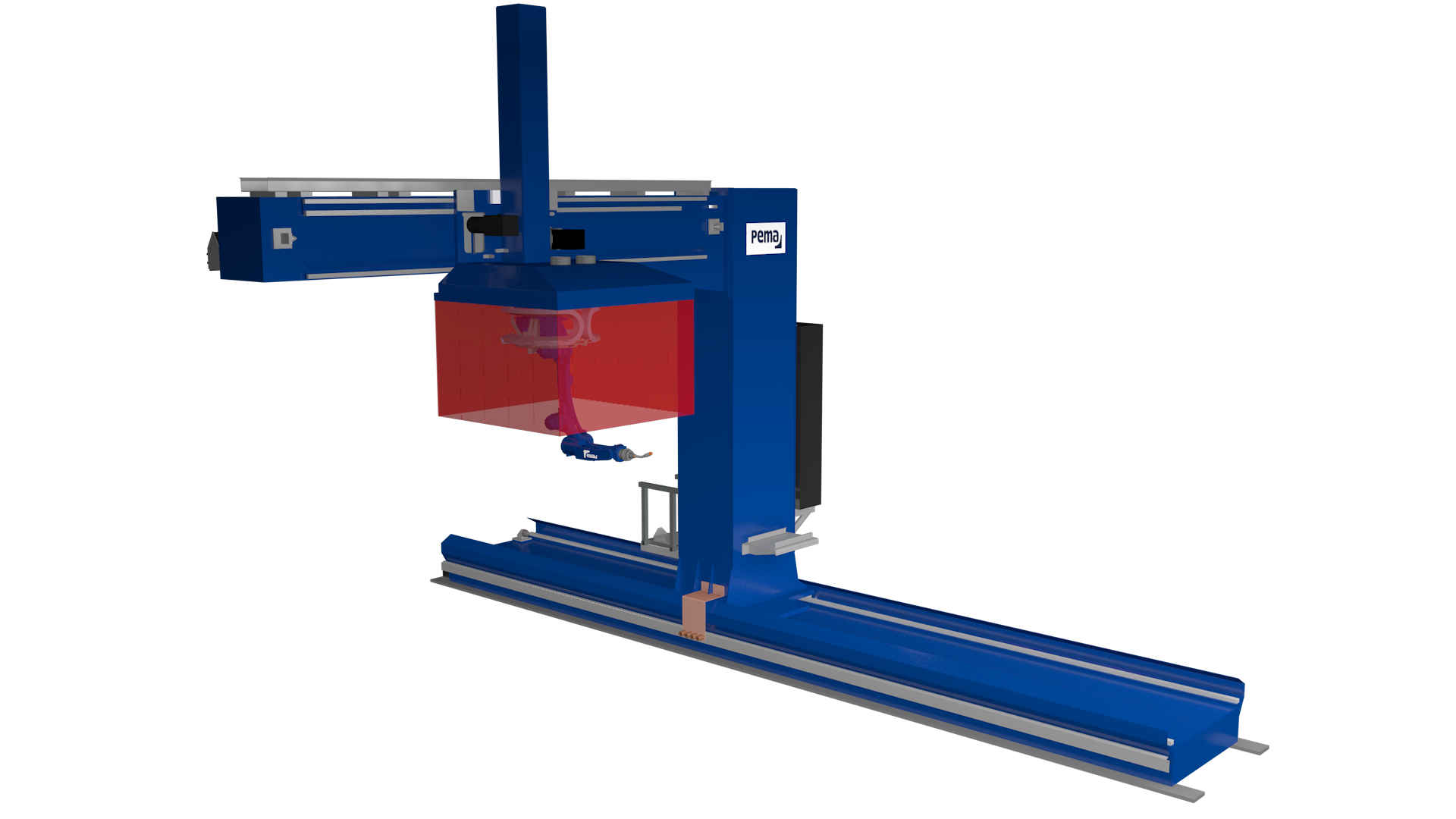

PEMA Skytrack is a compact robot welding solution designed for workshops that look to increase their production on flexibility and scalability. It combines state-of-the-art robotics, intelligent software, and advanced welding technology to deliver superior quality welds with exceptional efficiency.

PEMA SKYTRACK

PEMA Skytrack is an advanced robotic welding system designed optimize welding processes across various industries. Thanks to the small factory footprint, the solution is fast to install and easy to integrate into production routines. Robotic welding has never been this easy – just plug and weld.

Pemamek offers in-house expertise, welding tests with your workpieces, and advanced software with features like scanning and offline programming for efficient, error-free operation. PEMA’s robotic welding machine is ideal for heavy manufacturing, automating processes to reduce manual work and deliver high-quality results.

With 55+ years of experience, Pemamek trains your welders to become skilled robot operators and provides ongoing support through a dedicated service team, spare parts, and lifetime service agreements.

Customer story

The investment in PEMA robotic welding equipment was part of Harry Metall’s future strategy for developing its products and aims to be strong and competitive in growing and highly competitive markets.

“We manufacture big volumes of products but in small series. Therefore, it was crucial for us that the programming would be easy and production flexible,” tells Harry Salu, General Director at Harry Metall.

Robotic welding

Customer story

By investing in a PEMA robotic welding system, ASC aimed to further streamline its processes, boost efficiency, and elevate the quality of its output. During this process, the company also transitioned from using 2D models to 3D models.

Robotic welding vs manual welding

One of the most striking advantages of robotic welding is its unparalleled efficiency. ASC’s experience echoes this sentiment, with the PEMA station capable of outpacing traditional manual labor by a remarkable margin. For ASC, this meant a 50% reduction in manhours per workpiece.

PEMA WeldControl is an operating system for heavy robotic welding automation. It is a perfect tool for anyone working with challenging welds and workpieces with large variations in groove geometries.

PEMA WeldControl OFFLINE tackles the challenges of any high-mix low-volume production.

It is a great tool for weld path planning. One of the main benefits is a pre-analysis feature that makes it possible to test in advance which weldments are suitable for robot welding.

PathPlanner changes welding path planning once and for all. The software creates collision-free paths fully automatically from an existing or new 3D model. Enjoy optimized robot movements from approach to welding and exit even on complex workpieces and curved panels. Shift into efficient and fast welding path planning with the PathPlanner. Compatible with PEMA WeldControl 300.

The software called Vision 3D scans workpieces on the move and creates look-alike 3D models for the robot.

No existing 3D model or labor-intensive manual modeling is needed.

PEMA WeldControl 300 Scan for robotic welding is a tremendous aid for a welder.

It is a perfect tool when working with challenging welds or workpieces with large variations in groove geometries.

The all-new PEMA CellControl is an advanced software designed to enhance the efficiency and functionality of PEMA robot stations. Packed with user-friendly features and cutting-edge capabilities, PEMA CellControl places comprehensive workflow management at operators’ fingertips through an intuitive, browser-based touchscreen interface. This enhanced software simplifies and accelerates robot station operations, promising users ease, speed, and power.

designed for robotic welding

PEMA WeldControl is a state-of-the-art operating system integrated into PEMA robotic welding solutions, designed to enhance productivity in heavy robotic welding automation.

With our intelligent production system, welders can transition into operators after just a few days of training, making the process fast and accessible.

Developed by Pemamek, PEMA WeldControl is a software solution specifically dedicated to welding. Fully integrated into PEMA robotic solutions, it ensures seamless performance and consistent quality in demanding welding operations

“Thanks to the software, we could find an easy way for the operator to work, compensate tolerances, and improve welding seam preparation. It is difficult to find a software that is well-developed, fast to learn, and easy to operate.”

Rico Giebel Liebherr Rostock's Production Manager

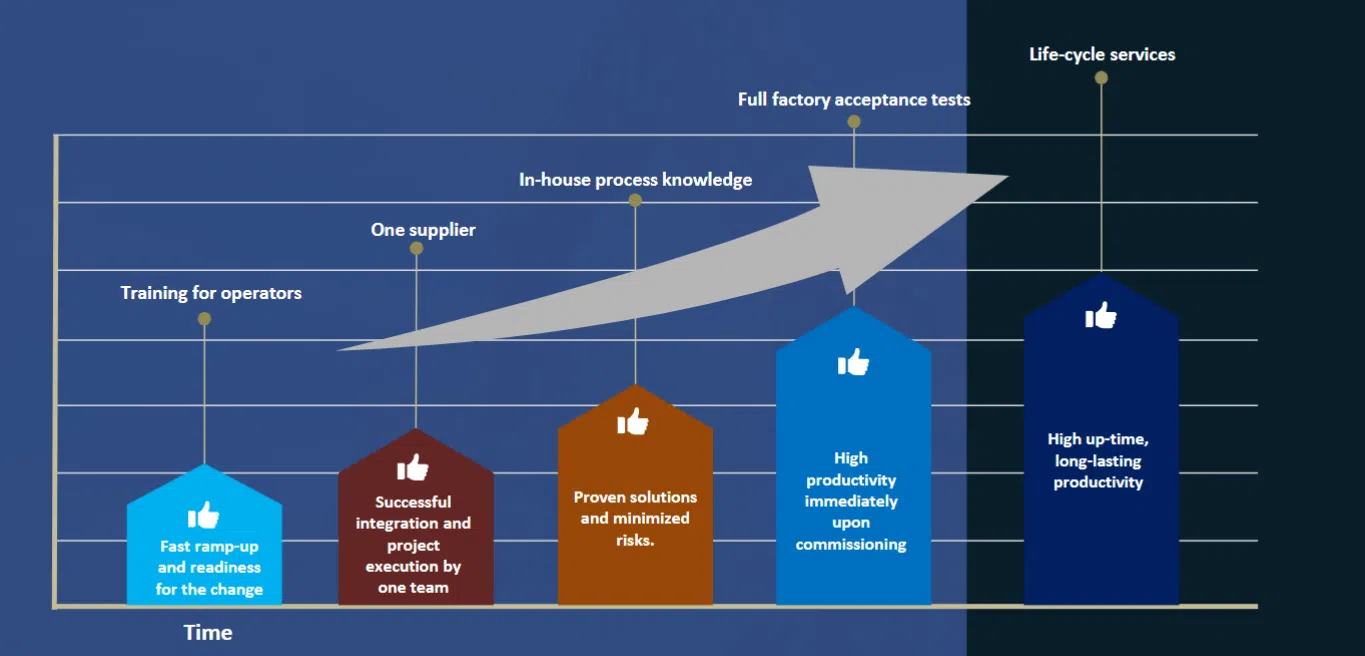

Trusted Partnership WITH PEMAMEK

One supplier

One supplier delivering the entire machinery and services. No broken phones, miscommunication or delays.

In-house expertise

Proven technology and process knowledge through in-house welding engineers, software development, design, and production.

Operator training

Our extensive operating and programming training enables fast ramp-up and facilitates transition.

Full acceptance test

The service includes testing with the customer’s workpiece and extensive final tests at the PEMA factory prior to shipping. No surprises during final commissioning.

Life-cycle service

Reliable support and service throughout project execution ensures that the ramp-up is fast and machine life-cycle long. High up-time and productivity.

PEMA robotic welding station is a real game-changer for the Estonian manufacturing company, Harry Metall. Not only does it deliver a high-quality final product, but it also boosts production capacity by optimising welding processes.

Custom robotic welding stations are a smart investment for the future. Explore 5 steps to a successful robotic welding investment.

The PEMA Curve concept is designed to generate real value fast for the customer. It significantly shortens the time between closing the contract and when the machine is running at the customer’s production site. Our workflow in every robotic welding project consists of the same steps.

Read what our customers say

The highest safety and welding efficiency at work, with 50 years of experience in the field. Read what our customers say about us.

Contact Us

Pemamek Ltd