Robotic welding systems improve productivity and quality

In the highly competitive heavy fabrication industry, a company’s competitive edge needs to be developed all the time. Robotic welding systems improve productivity and quality, providing the focus and optimization the company needs, to be more dynamic and deliver more value to the customer.

Robotic welding systems can be used to automize certain welding tasks and they offer several benefits over traditional welding methods, including improved accuracy, consistency, and efficiency. To operate a robotic welding system, operators program the robot’s movements and welding parameters using specialized software. At Pemamek, our solutions come with the in-house developed software family PEMA Core.

To raise the level of automation and improve overall productivity, welding manufacturing operations must be considered as a chain of process steps and should be arranged according to lean manufacturing principles.

When implementing factory automation, robot production cells are the basic building blocks for modern factories. The work steps that are time-consuming and no longer bring value to the production chain, are eliminated from the work chain as robots are put in work.

Complete robotic welding systems include:

- Reliable pre-analysis: Virtual robotic solution design through 3D-modeling and simulation

- Typically achieved automation rate in welding from 50 to 80%

- Deposit rates up to 9 kg per automatic program running hour with only one MIG/MAG torch

- Systems can be utilized 24/7 and 8760 hours per year

- All components and services from one supplier

Benefits of investing in a robotic welding system:

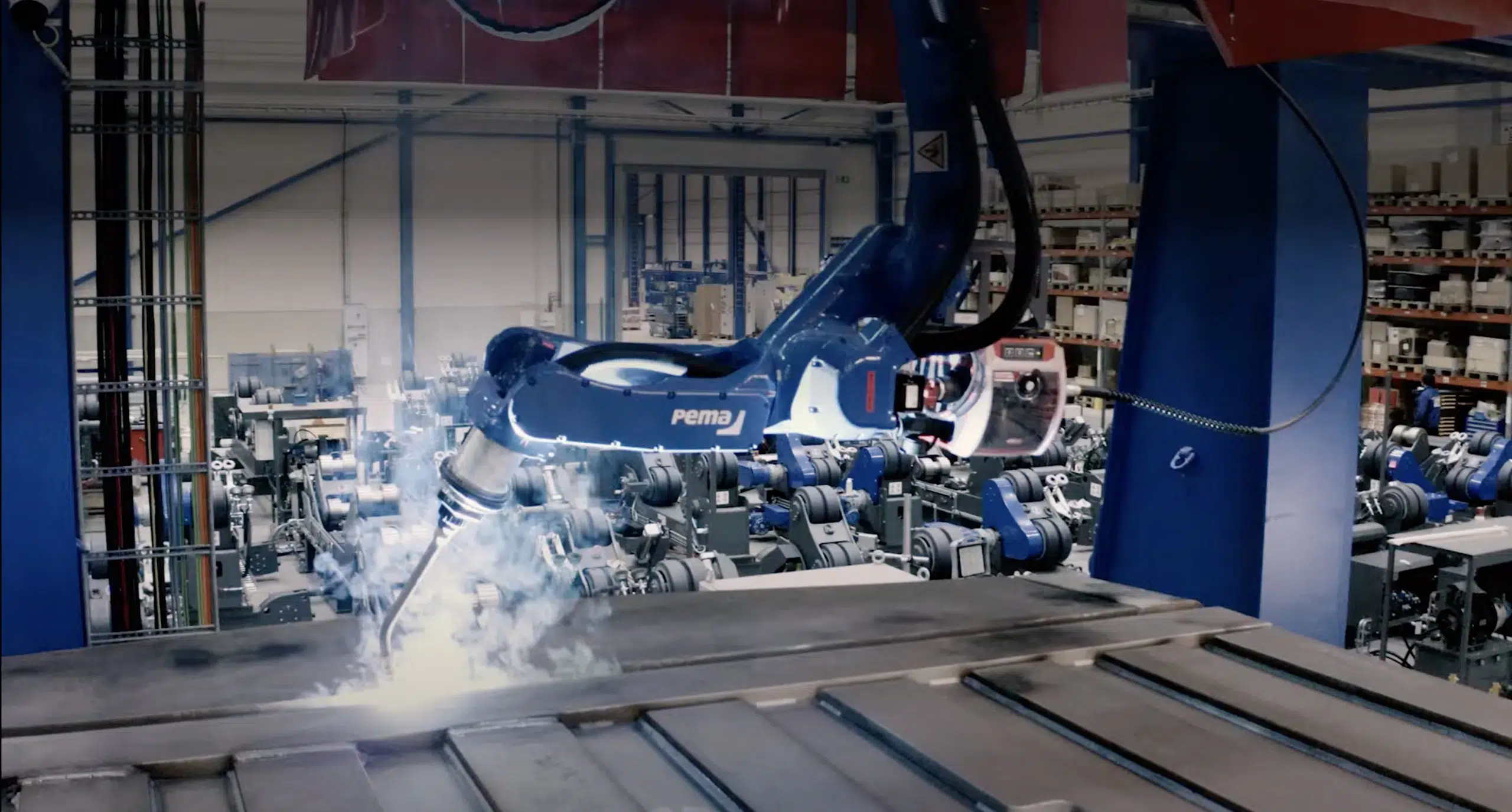

Increased efficiency and speed: Robotic systems automate the welding process, which leads to faster production times compared to manual welding. Robots can work continuously without breaks, minimizing downtime and boosting arc-on time, which increases overall throughput.

Consistent quality: Robots maintain high precision, producing consistent and repeatable welds with minimal errors. This leads to fewer defects, reducing the need for rework and improving product quality.

Improved safety and ergonomics: Robotic welding systems handle dangerous tasks, reducing the risk of injury for workers. They also allow for better ergonomic positioning of workpieces, ensuring that welding is performed in the optimal position.

Flexibility and adaptability: Modern robotic systems can adapt to varying production needs, whether dealing with complex geometries or one-off productions. With advanced programming and simulation tools, even high-mix, low-volume production environments benefit from automated welding.

Cost-effectiveness: Despite the initial investment, robotic welding offers a fast return on investment by reducing labor costs, minimizing material waste, and speeding up production cycles. Tailored solutions ensure the system fits the specific needs of a workshop, maximizing productivity.

Well-designed robotic welding cells equal more productivity, better safety, high competitiveness, and fast return on investment. When robotic solutions are implemented well, they enable highly adaptive and efficient production.

Miika Kartano, Application Manager, Software

Versatility with modular robotic welding systems

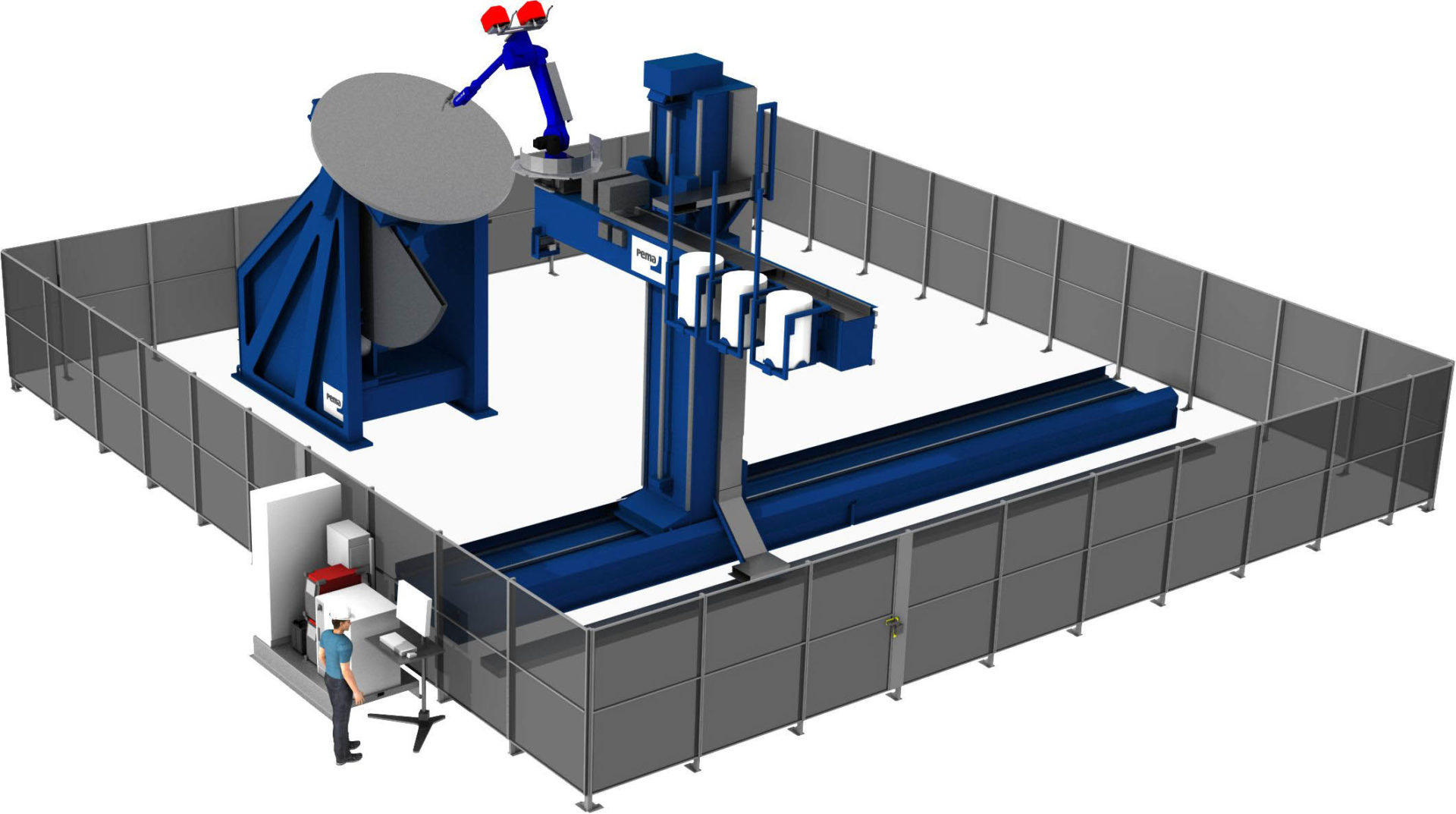

Effective and accurate workpiece handling is one of the most important parts of successful robot welding. When robotic welding cells are based on modular robot tracks and positioners, the design of the production cells can be optimized by selecting the most suitable handling module.

A 3D modeling of the robotic welding cell and welding reachability analysis verify the selected layout and draw the footprint of the cell.

Technical details of a robotic welding system

During the past decade, robotic welding has been one of the most increased industrial applications. Because of the flexibility and level of productivity that those solutions bring; robotic welding systems can be designed both for one-off or mass production, large-reaching dimensions, and offline programming systems.

- Typically, the robotic welding system consists of a workpiece handling solution and gantry (half portal) with one to three linear axis.

- The robotic welding cell comes with suitable programming and cell control software systems that are chosen according to the machinery and production needs.

- Additionally, robotic welding process evaluation, proper safety equipment for the robotic cell, and machine life-cycle management services come as standard.

Each unit of the complete solution, such as handling equipment, welding process or the software system used, is analyzed and selected according to production requirements and customer needs.

Pemamek’s typical complete robotic system consists of a workpiece handling solution, a gantry (half portal) with one to three linear axis, PEMA WeldControl 300, CellControl, safety equipment, as well as welding process evaluation and machine life-cycle management services.