To stay competitive in a rapidly evolving industry, Lecitrailer made a strategic move toward welding automation. The investment marks a significant leap toward smarter, more efficient trailer manufacturing.

In the heart of Spain’s industrial sector, Lecitrailer, the country’s leading trailer and semi-trailer manufacturer, has taken bold steps toward the future of automated manufacturing. With a strong presence in Spain, France, Italy, Portugal, and ongoing expansion into Northern Europe, Latin America, and Africa, the Zaragoza-based company is committed to staying ahead of the curve.

Faced with a growing shortage of skilled welders and the need to consistently improve product quality, Lecitrailer saw robotic welding not just as a technological upgrade, but as a strategic investment.

“Automation plays a fundamental role in our future, especially as qualified labor becomes harder to find,” explains Juanjo Martín, Head of Robotic Welding Installations and Technical Design at Lecitrailer.

To meet these challenges, Lecitrailer partnered with Pemamek to implement its first robotic welding solution, enhancing production efficiency, boosting quality, and preparing the company for long-term competitiveness in a global market.

A strategic leap into automation

“At Lecitrailer, we specialize in manufacturing large, complex chassis in small series. This requires a very flexible and powerful programming solution, which is exactly what Pemamek brought to the table,” explains Martín.

The decision to invest in automated welding was driven primarily by a shortage of skilled welders, a growing concern across the industry. Lecitrailer saw robotic welding as an essential step not only to maintain and elevate the quality of the products but also to stabilize production in the long term.

“The main reasons we chose Pemamek as our partner to automate the welding process were, above all, their programming software. We believe it’s extremely powerful compared to others on the market and offers greater flexibility when programming large components. We also appreciated that the software is developed in-house by Pemamek,” says Martín.

Advanced robotic welding with Pemamek

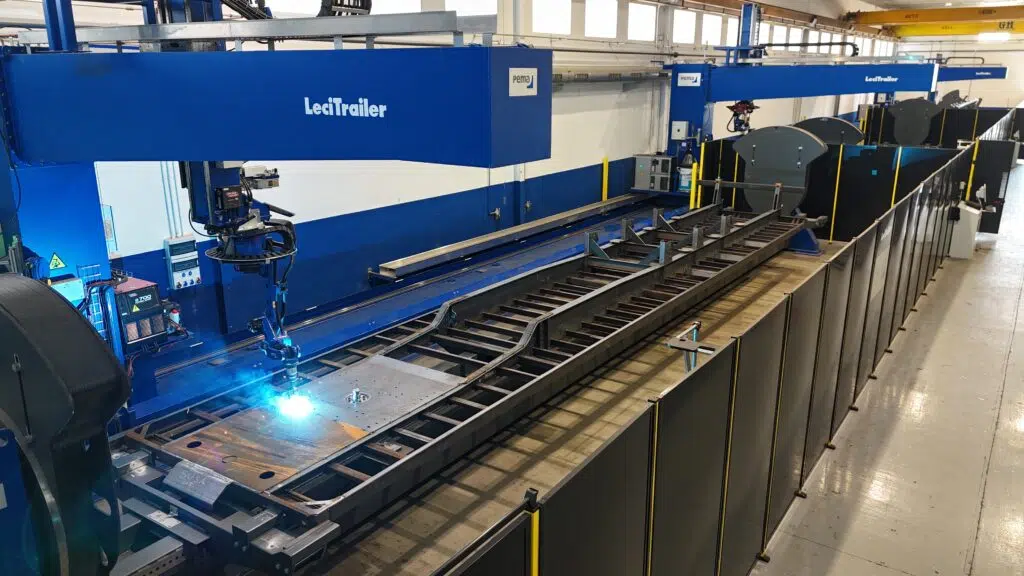

Pemamek and Lecitrailer co-developed a custom robotic welding station composed of three independent workstations that share a longitudinal track system. This unique configuration enables robotic welding heads to travel between stations and even work collaboratively, allowing two or three robots to operate in a single station if needed. Future expansion has already been discussed, with the potential to integrate up to four or five additional robots as production demands increase. The system is powered by PEMA WeldControl 300, a software known for its flexibility and user-friendliness.

“PEMA’s software is developed in-house, which is a huge advantage. It’s adaptable, fast, and gives us offline programming tools like PathPlanner, which are critical for programming large and complex parts,” notes Martín.

One interesting decision in the implementation was to install the robotic welding station outside of LeciTrailer’s main production line. This separation ensured that no disruption occurred during installation or ramp-up. Chassis are assembled in the main line, sent to the robotic station for welding, and then re-integrated into the normal process flow for painting and final assembly.

“This setup allowed us to implement the technology without pausing production. It was a smooth integration,” Martín emphasizes.

From installation to execution: a true partnership

“The cooperation has lasted over two years, from commercial discussions with Peter Senz, to engineering with Henry Kartano, and then programming and ramp-up with Eetu Mertanen and Patrik Kivelä. The support has been complete and constant,” Martín shares.

For Lecitrailer, local support was non-negotiable. “The opening of Pemamek Iberia in Zaragoza has been a game-changer,” says Martín. “Having experts like Patrik nearby means faster service, better training, and a partner that understands our local needs.”

Equally important was how quickly Lecitrailer’s team could adopt the technology. The learning process for the welders and machine operators has been relatively fast, and they were able to master the robotic welding cell within just a few months.

“Of course, it took some time to fully master the equipment, but overall, it’s easy to use, especially for people already familiar with robotic systems. Our team of operators and programmers adapted quickly to the new robotic welding setup, thanks in large part to the support and the user-friendliness of both the WeldControl 300 programming software and the CellControl system.”

Today, two dedicated programmers use Pemamek’s software daily to configure new chassis models. Advanced offline tools like Path Planner support them in this task, streamlining Lecitrailer’s programming process.

Advice for others considering automation

Martín has a clear message for other manufacturers thinking about robotic welding:

“Not everything can or should be automated. Think carefully about which parts to automate, and once that’s clear, work with a partner like Pemamek who can customize a solution for you.”