Pressure vessel manufacturing

With PEMA, you get proven solutions and decades of expertise to tackle the common challenges most pressure vessel manufacturers in the US face.

1. Overcome the shortage of skilled welders

2. Combine high quality with efficiency

3. Accelerate the transition to automation

4. Receive proper training & local service

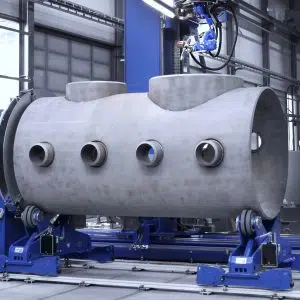

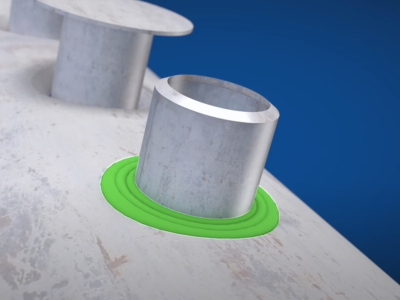

Our dedicated nozzle welding solution is fully automated, efficient, and versatile. It delivers not only nozzle connection welding, but also robust capabilities for welding circular and longitudinal seams, support legs, and various external components.

Leading pressure vessel manufacturers rely on PEMA assembly and welding stations because of their exceptional precision, user-friendly operation, and impressive return on investment. These compelling advantages make PEMA the trusted choice in the industry.

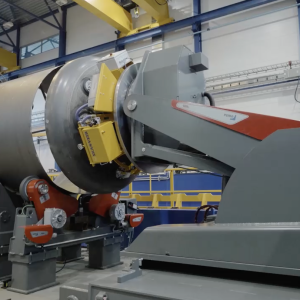

PEMA heavy-duty positioner and Column & Boom with welding and cladding processes can be used to fabricate dish ends. Integrated control of machinery enables processing for both internal and external surfaces of the dish end.

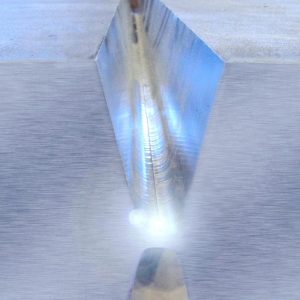

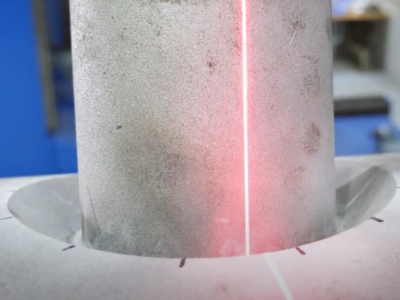

PEMA CM55 is a new-generation equipment for circumferential milling.

PEMA CM55 improves welding efficiency and quality, but also significantly reduces defect rates. The machine is an ideal solution for milling circular seams and thick materials

Experience live online demonstrations of PEMA welding solutions.

See the technology in action and discuss its potential for your business with our experts.

Book your demo today!

Every PEMA solution is operated with one or several PEMA Core software. All our software are created by our experienced in-house team. It ensures the most reliable, advanced, and easy real-life use of PEMA machinery. One supplier for hardware and software makes life easier.

Pemamek north america

Contact Us

Pemamek Ltd

Pemamek Oy