In today's fast-paced manufacturing landscape, welding fabrication has emerged as a cornerstone for achieving efficiency and precision. According to John Miller, a leading expert in the welding fabrication industry, “The integrity of a finished product heavily relies on the quality of its welding fabrication process.” This statement underscores the significance of welding fabrication not only in the creation of robust structures but also in enhancing overall production workflows.

As modern manufacturing increasingly embraces automation and advanced technologies, the role of welding fabrication becomes even more critical. It serves as a bridge that connects various components, ensuring that they not only fit together seamlessly but also withstand the demands of operational use. With the ability to provide specialized solutions tailored to different industries, welding fabrication is simply indispensable in meeting the high standards of today’s manufacturing environments.

Moreover, the efficiency achieved through proficient welding fabrication can lead to substantial cost savings and increased productivity, making it a vital consideration for manufacturers looking to enhance their competitive edge. Embracing the advancements in welding fabrication allows manufacturers to streamline processes, reduce waste, and ultimately deliver better products to market, reinforcing its essential role in modern manufacturing efficiency.

Welding fabrication plays a pivotal role in modern manufacturing, serving as a fundamental process that enhances product quality and operational efficiency. According to a report from the American Welding Society, the welding industry contributes over $300 billion to the U.S. economy each year, highlighting its significance in various manufacturing sectors. By providing strong, durable joints and enabling complex designs, welding fabrication helps manufacturers reduce assembly time and costs, ultimately improving the overall production process. The integration of advanced technologies, such as robotic welding systems, further amplifies these benefits, allowing for increased precision and repeatability.

Tips: When considering welding techniques, opt for automated solutions where feasible. Automation not only enhances consistency but also helps mitigate risks associated with manual welding, such as human error or fatigue. Furthermore, investing in staff training on new welding technologies can yield significant returns by improving workforce efficiency and safety.

Moreover, the versatility of welding fabrication allows manufacturers to adapt to diverse market needs rapidly. According to a study by the National Institute of Standards and Technology, about 90% of manufacturers cite welding as essential for their product development and innovation strategies. This adaptability fosters innovation, enabling companies to create custom solutions for their clients while maintaining high efficiency. By ensuring robust quality control throughout the welding process, manufacturers can meet stringent safety and quality standards demanded by today's competitive market.

Tips: Regularly perform maintenance checks on welding equipment to ensure optimal performance and minimize downtime. Additionally, embrace continuous learning through workshops or online courses to stay updated with emerging welding techniques and industry standards.

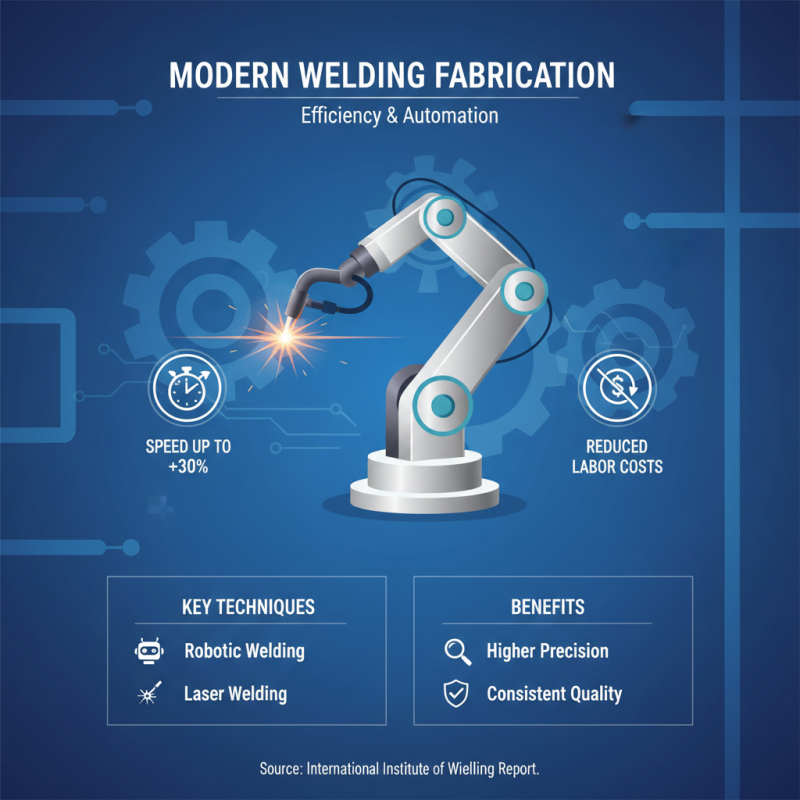

Welding fabrication is a cornerstone of modern manufacturing, enabling the efficient assembly of complex structures and components. Key techniques that enhance efficiency include automated welding processes, such as robotic welding and laser welding. According to a report by the International Institute of Welding, automation in welding can improve production speed by up to 30% while simultaneously reducing labor costs. These advancements not only optimize the manufacturing process but also ensure higher precision and consistency in weld quality.

Another essential technique in welding fabrication is the application of advanced materials. The use of high-strength steel and specialized alloys can lead to lighter, more durable components, which are crucial in applications ranging from automotive to aerospace manufacturing. The Welding Research Council highlighted that adopting such materials can result in a 20% reduction in weight, contributing to increased energy efficiency and performance in final products. As manufacturers continue to embrace these welding fabrication techniques, they position themselves to meet the growing demand for efficiency and innovation in an increasingly competitive marketplace.

Welding fabrication plays a pivotal role in enhancing manufacturing efficiency by streamlining production processes across various industries. According to the American Welding Society, welding contributes approximately $300 billion to the U.S. economy each year, demonstrating its significance in modern manufacturing. By integrating advanced welding techniques and automation, manufacturers can achieve more adaptable production lines, ultimately reducing cycle times and increasing throughput. Reports indicate that with the implementation of robotic welding systems, companies can enhance productivity by 30-50%, while also improving the consistency and quality of the final products.

Tips: When considering welding fabrication techniques, it's essential to evaluate the specific needs of the project. Employing MIG and TIG welding can significantly improve precision and reduce rework, saving both time and resources. Additionally, investing in training for skilled welders can lead to improved safety and more efficient workflows.

Furthermore, the efficiency derived from welding fabrication extends beyond productivity. Enhanced joint strength and durability reduce the need for costly repairs and replacements, thereby decreasing overall lifecycle costs. A report from the International Institute of Welding states that optimizing welding procedures can reduce material waste by up to 20%, supporting sustainability initiatives in manufacturing. By prioritizing welding fabrication, companies can not only streamline their production processes but also contribute positively to their bottom line and environmental goals.

Tips: Regular maintenance of welding equipment is crucial for maintaining high efficiency levels. Consistent checks and calibrations can prevent unexpected downtime and ensure that production remains smooth and uninterrupted.

Welding fabrication plays a crucial role in modern manufacturing, yet it comes with its own set of challenges. One significant issue is the skill gap in the workforce. As technology evolves, the demand for skilled welders proficient in advanced techniques and equipment rises. Manufacturers often struggle to find qualified personnel, which can lead to delays and increased costs. To address this, companies are investing in training programs and apprenticeships to cultivate a new generation of skilled workers, ensuring that they remain competitive in a rapidly changing industry.

Another challenge in welding fabrication is maintaining quality and precision in the production process. The manual nature of welding can introduce inconsistencies that may affect the final product. Manufacturers are turning to automation and robotic welding solutions to enhance accuracy and reduce human error. By integrating advanced technologies, they can improve consistency while also increasing production speeds. Implementing strict quality control measures is also essential, enabling manufacturers to identify and rectify issues before they impact the overall output. Through a combination of workforce development and technological innovation, the challenges of welding fabrication can be effectively tackled, contributing to greater manufacturing efficiency.

The landscape of welding fabrication is evolving rapidly, driven by advancements in technology and the increasing demand for efficiency in modern manufacturing. Industry reports indicate that the global market for welding fabrication is expected to reach approximately $30 billion by 2026, growing at a compound annual growth rate (CAGR) of 5.4%. This growth is fueled by innovations such as automation, robotic welding, and integration of artificial intelligence (AI) to enhance precision and reduce cycle times. As manufacturers strive to improve production efficiency and reduce costs, welding fabrication becomes a pivotal element of their operational strategies.

Future trends highlight the pivotal role of digital transformation in welding processes. The integration of Industry 4.0 principles is set to revolutionize traditional welding practices. According to a recent study by the Manufacturing Institute, over 70% of manufacturers are investing in new technologies that include CAD software and IoT-enabled devices to optimize welding practices. Furthermore, predictive maintenance powered by AI can significantly decrease downtime, ensuring that fabrication systems run more efficiently. These advancements not only streamline manufacturing processes but also contribute to sustainability goals by reducing waste and energy consumption, positioning welding fabrication as an essential component for future manufacturing efficiency.

| Welding Technique | Efficiency Improvement (%) | Common Applications | Future Trends |

|---|---|---|---|

| MIG Welding | 20% | Automotive, Construction | Automation Integration |

| TIG Welding | 15% | Aerospace, Thin Metals | Advanced Materials |

| Stick Welding | 10% | Heavy Equipment, Maintenance | Robotic Applications |

| Flux-Cored Welding | 25% | Shipbuilding, Construction | AI and Machine Learning |

| Laser Welding | 30% | Electronics, Automotive | Enhanced Precision Techniques |

Contact Us

Pemamek Ltd