In the rapidly evolving landscape of automation and control, the role of a rotary positioner has gained significant prominence across various industries. According to a recent market report by Allied Market Research, the rotary positioner market is projected to reach $1.5 billion by 2027, driven by the increasing need for precise control in processes such as manufacturing, oil and gas, and pharmaceuticals. These devices are essential for applications demanding high accuracy and reliability, as they amplify the efficiency of actuator systems by enabling precise positioning of valves and dampers.

Dr. Emily Carter, a leading expert in automation technologies, emphasizes the critical role of rotary positioners in modern industrial applications: "The integration of rotary positioners not only enhances operational efficiency but also significantly reduces downtime, ultimately leading to increased profitability." As industries continue to embrace automation, understanding the applications and benefits of rotary positioners becomes crucial. With various considerations such as installation, cost, and compatibility with existing systems, stakeholders must navigate this technology landscape thoughtfully to harness its full potential.

Rotary positioners are essential devices in various industrial applications, designed to precisely control the angular position of objects. Their functionality centers around the ability to turn loads to specific angles and maintain those positions with high accuracy. They typically work through a combination of drive mechanisms, such as electric motors or pneumatic systems, along with feedback devices like encoders and limit switches. This ensures that the rotary positioner can achieve and sustain the desired position even under varying load conditions.

The versatility of rotary positioners makes them suitable for a range of industries, including manufacturing, automation, and robotics. They can be utilized in applications such as assembly lines, CNC machinery, and robotic arms, where precise positioning is crucial for operational efficiency. Additionally, they can accommodate different payloads and be integrated with various control systems, enhancing their adaptability in complex industrial environments. As companies continue to seek automation solutions that improve productivity and precision, understanding the functionality of rotary positioners becomes increasingly important for optimizing performance and achieving desired outcomes.

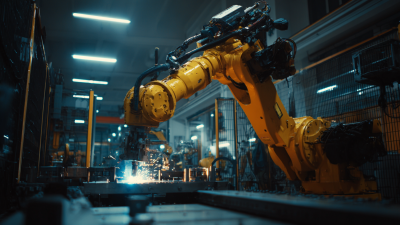

Rotary positioners play a critical role across various industries, enhancing the precision and efficiency of numerous applications. In manufacturing, these devices are commonly used in assembly lines for accurate positioning of components during the fabrication process. By enabling precise rotational movement, rotary positioners facilitate the automation of tasks such as welding, painting, and part placement, significantly improving production speed and consistency while reducing labor costs.

In the field of robotics, rotary positioners are essential for enabling complex movements and tasks that require a high degree of accuracy. They are employed in robotic arms that assemble products, where precise positioning is crucial to ensure proper alignment and function. Additionally, in the aerospace sector, these positioners aid in the testing and calibrating of aircraft components, allowing engineers to achieve exact specifications and maintain safety standards. Their ability to handle various loads and operate in challenging environments makes rotary positioners invaluable across these diverse applications.

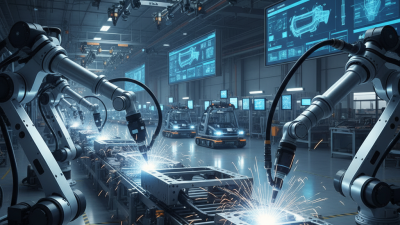

The integration of rotary positioners in automated systems has revolutionized the manufacturing and industrial landscape, delivering enhanced precision and efficiency. Rotary positioners are pivotal in applications that require precise angular motion control, such as robotics, assembly lines, and automated packaging. According to a report by the International Federation of Robotics, the adoption of advanced positioning technologies has been shown to improve overall production efficiency by up to 30%, underscoring their value in modern automated systems.

One of the key benefits of using rotary positioners is their ability to facilitate complex motion in cyclic processes. They provide consistent positioning with high repeatability, which is crucial for tasks like welding, painting, or material handling. Furthermore, a survey by the Automation Industry Association highlighted that companies implementing rotary positioning systems noted a 25% reduction in operational downtime due to improved reliability and maintenance intervals. Such performance metrics make rotary positioners an integral part of any automated solution aiming for operational excellence.

Tip: When selecting a rotary positioner, consider its torque and speed specifications relative to your application needs. Matching these characteristics can significantly enhance the effectiveness and longevity of your system. Additionally, ensure to evaluate the compatibility of the positioner with your existing control systems to facilitate seamless integration and maximize productivity.

When selecting rotary positioners, several critical factors must be considered to ensure optimal performance in various applications. One of the primary considerations is the type of actuator used; pneumatic and electric actuators are most common, each with distinct advantages. According to a report by MarketsandMarkets, the global market for electric actuators is expected to reach $12.56 billion by 2025, reflecting a growing preference for electric systems that provide greater precision and efficiency. Users should also evaluate the positioning accuracy required for their specific applications, as this can significantly influence the choice of rotary positioner.

Moreover, the environmental conditions in which the positioners will operate cannot be overlooked. Factors such as temperature, humidity, and exposure to corrosive substances affect the longevity and reliability of the equipment. For example, harsh environments may necessitate specialized coatings or materials to prevent degradation. Additionally, the load capacity and speed of movement are vital criteria; selecting a positioner capable of handling the required torque and travel speed can prevent operational failures and enhance overall system effectiveness. With the increasing automation across industries, ensuring that the chosen rotary positioners meet these specifications is essential for maintaining productivity and efficiency.

The future trends and innovations in rotary positioner technology are set to dramatically reshape various industries, including manufacturing, robotics, and automation. As the demand for precision and efficiency in operations continues to rise, advancements in rotary positioners are addressing these needs by integrating smarter control systems and enhancing their adaptability.

For instance, the incorporation of artificial intelligence allows for real-time adjustments and predictive maintenance, significantly reducing downtime and improving overall operational efficiency.

Furthermore, the development of more compact and lightweight designs is enabling rotary positioners to be utilized in applications where space is limited, without compromising performance. Innovations in materials and production techniques are contributing to this trend, allowing for the creation of robust components that can withstand harsh environments.

Additionally, wireless technology is emerging as a key feature, facilitating seamless integration with IoT systems and remote monitoring capabilities, making it easier for operators to manage and optimize processes from a distance. As these technologies evolve, we can expect rotary positioners to play an increasingly critical role in driving automation and efficiency across various sectors.

Contact Us

Pemamek Ltd