In the world of welding, efficiency and precision are paramount, particularly when tackling intricate projects that require consistent alignment and support. One of the essential tools often overlooked in the welding process is the welding roller. These devices play a crucial role in stabilizing cylindrical workpieces, thereby enhancing productivity and safety during operations.

According to a recent industry report by the American Welding Society, the use of appropriate welding rollers can increase workflow efficiency by up to 30%, significantly reducing project completion times while ensuring high-quality welds.

Experts in the field, such as Dr. Mark Stevenson, a leading authority on welding technology, note that

"investing in quality welding rollers is not just a choice; it's a necessity to achieve optimal alignment and uniform welds, which, in turn, minimizes material waste."With the continuous advancements in welding techniques and materials, selecting the right type of welding roller for specific projects has become critical. This guide will explore the top 10 welding rollers that can elevate your welding projects, ensuring you have the tools necessary for effective and efficient welds.

Welding rollers play a crucial role in modern fabrication processes, offering a series of advantages that enhance both efficiency and safety. According to a report by the American Welding Society, nearly 30% of welding defects can be traced back to improper positioning and movement of materials. By utilizing high-quality welding rollers, fabricators can ensure smoother movement and consistent alignment of components, ultimately improving weld quality and reducing the risk of errors.

When selecting welding rollers, it’s essential to consider their load capacity and compatibility with various materials. Many of the top-rated models can accommodate up to 5,000 pounds, allowing for the easy handling of large pipes and frames. Additionally, investing in adjustable welding rollers helps in managing different sizes, enhancing versatility on the job site.

Tips: Always check the specifications of your welding rollers to match them with the project's requirements. Regular maintenance, such as lubricant application on roller bearings, can significantly extend their lifespan and performance efficiency. Furthermore, don’t underestimate the importance of safety; ensure that the rollers are designed with sturdy brakes to prevent unexpected movements during the welding process.

When selecting welding rollers, it is crucial to focus on key features that enhance the efficiency and precision of your welding projects. First and foremost, consider the load capacity of the rollers. High-quality welding rollers should support various weights, ensuring stability and reducing the risk of accidents. Additionally, the build material plays a significant role; rollers made from durable materials like steel or reinforced plastic offer greater longevity and resistance to wear and tear.

When selecting welding rollers, it is crucial to focus on key features that enhance the efficiency and precision of your welding projects. First and foremost, consider the load capacity of the rollers. High-quality welding rollers should support various weights, ensuring stability and reducing the risk of accidents. Additionally, the build material plays a significant role; rollers made from durable materials like steel or reinforced plastic offer greater longevity and resistance to wear and tear.

Another important aspect is the adjustability of the rollers. Look for models that allow for height and width adjustments, enabling you to accommodate different workpieces with ease. Furthermore, smooth rolling action is essential for maintaining consistent welding speed and accuracy. Bearings that facilitate easy movement can reduce operator fatigue and improve overall workflow. Investing in welding rollers with these key features will make a tangible difference in the effectiveness of your projects.

When it comes to efficient welding projects in 2025, having the right tools is crucial. Among these tools, welding rollers are indispensable for ensuring precise and stable joint alignment. According to a report by MarketsandMarkets, the welding equipment market is projected to reach $21.6 billion by 2026, highlighting the increasing reliance on advanced welding technologies and equipment. As a part of this industry, welding rollers help enhance productivity, reduce labor costs, and improve the overall quality of welds.

The top five must-have welding rollers for upcoming projects include powered turning rolls with variable speed capabilities, which allow for optimal control over the workpiece during welding. Additionally, self-aligning rollers are gaining traction due to their ability to minimize setup time and maximize efficiency. Recent data from the American Welding Society indicates that utilizing high-quality welding rollers can reduce welding time by up to 30%, making them essential for any serious welder. Furthermore, lightweight and portable models are becoming popular, catering to the demand for versatile equipment in various job settings.

Embracing these innovations will not only streamline the welding process but also enhance the end product's quality.

In the world of welding, the efficiency of projects can significantly be influenced by the quality and type of welding rollers used. A recent comparative analysis highlights various leading brands that stand out in the market, each offering unique features tailored to specific welding needs. The growing demand for welding products is reflected in the data, with the global welding products market projected to reach a valuation of USD 16.21 billion by 2032. This substantial growth indicates a robust interest in high-quality equipment that can enhance productivity and precision.

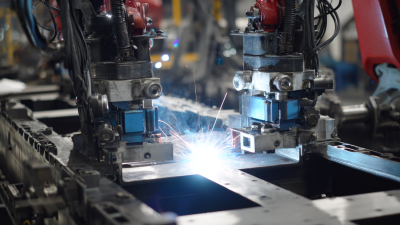

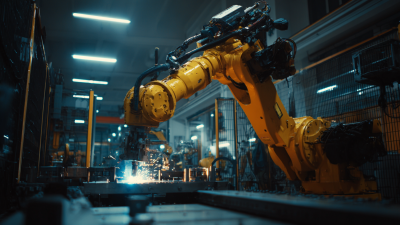

Moreover, the importance of specialized equipment is underscored by the projected growth of the robotic welding market, which is poised to expand substantially in the coming years. This market segment, driven by advancements in automation, is expected to play a critical role in industries such as automotive and manufacturing. As the market landscape evolves, it is essential for professionals to stay informed about innovations and trends among top welding roller brands, ensuring they have the best tools for efficient and effective welding projects.

Welding rollers are essential tools for enhancing the efficiency of welding projects, particularly in large-scale manufacturing settings. According to a report by the American Welding Society, proper use of welding rollers can reduce setup time by up to 30%, allowing for quicker project turnaround. This is primarily due to their ability to provide stability and support to heavy workpieces, which minimizes the need for additional handling and adjustment during the welding process.

To maximize efficiency with welding rollers, it's crucial to select the right type based on the project's specific needs. For instance, utilizing adjustable rollers can accommodate various sizes of workpieces, ensuring optimal fit and stability. Additionally, implementing the latest technology in roller design—such as those equipped with automated positioning features—can further enhance productivity. A study published in the Journal of Manufacturing Processes indicates that projects utilizing advanced rollers reported a 25% increase in welding speed while maintaining high-quality welds. Thus, investing in the appropriate welding rollers not only streamlines operations but also contributes to superior outcomes in welding applications.

| Model | Load Capacity (lbs) | Roller Diameter (inches) | Adjustment Type | Price Range ($) |

|---|---|---|---|---|

| Model A | 1,500 | 6 | Manual | 150 - 200 |

| Model B | 2,500 | 8 | Electric | 250 - 300 |

| Model C | 3,000 | 10 | Manual | 300 - 400 |

| Model D | 4,000 | 12 | Pneumatic | 400 - 500 |

| Model E | 2,000 | 7 | Manual | 200 - 250 |

| Model F | 5,000 | 15 | Electric | 500 - 600 |

| Model G | 3,500 | 9 | Pneumatic | 350 - 450 |

| Model H | 1,800 | 6 | Manual | 180 - 220 |

| Model I | 2,300 | 8 | Electric | 220 - 270 |

| Model J | 4,500 | 14 | Manual | 450 - 550 |

Contact Us

Pemamek Ltd