In the rapidly evolving landscape of manufacturing, robotic welding systems have emerged as pivotal tools that enhance productivity and precision across various industries. As companies strive for efficiency and cost-effectiveness, these advanced systems are transforming the traditional approaches to welding, offering solutions that minimize human error and maximize output. The adoption of robotic welding technology is not merely a trend; it is becoming a necessity for manufacturers aiming to remain competitive in an increasingly automated world.

The year 2023 marks a significant turning point in the integration of robotic welding systems within the manufacturing sector. As technological advancements continue to reshape welding practices, systems are becoming more sophisticated, incorporating features such as AI-driven automation and enhanced safety protocols. This comprehensive guide is designed to explore the top 10 robotic welding systems currently available, highlighting their unique features and benefits. By understanding which systems are leading the market, manufacturers can make informed decisions that align with their operational goals, paving the way for a more efficient and productive future.

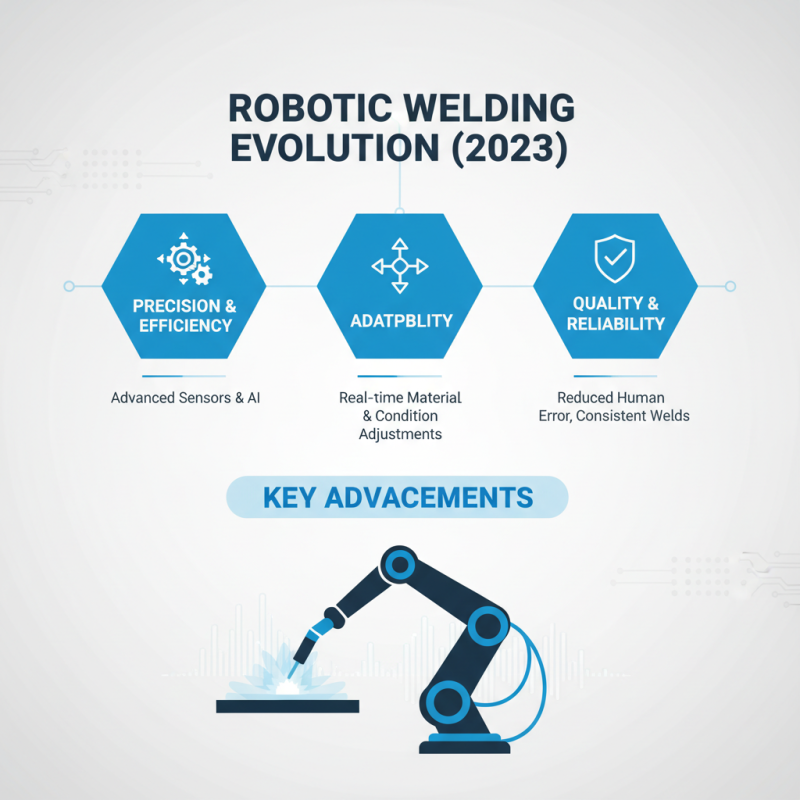

Robotic welding technology has evolved significantly in 2023, marked by advancements in precision, efficiency, and adaptability. Modern robotic welding systems are equipped with sophisticated sensors and artificial intelligence, allowing them to adapt in real-time to variations in materials and weld conditions. This level of automation not only enhances the quality of welds but also significantly reduces the risk of human error, leading to more consistent and reliable manufacturing outcomes.

In addition to improved accuracy, today's robotic welding systems are designed for versatility. They can handle a wide range of materials, including metals of varying thicknesses and compositions, which makes them ideal for various industries, from automotive to aerospace. Furthermore, the integration of IoT technology enables real-time monitoring and data analysis, optimizing production processes and allowing manufacturers to respond swiftly to potential issues. This technological synergy positions robotic welding as a cornerstone of efficient manufacturing, driving productivity and ensuring high-quality standards in 2023.

When selecting a robotic welding system for efficient manufacturing in 2023, several key features should be at the forefront of consideration. A report from MarketsandMarkets highlights that the global robotic welding market is projected to reach $5.4 billion by 2027, driven by increasing demands for high-quality and precise welding processes. This suggests that investing in advanced robotic systems can lead to significant returns through enhanced operational efficiency.

One crucial feature to consider is the system's adaptability to different welding techniques, such as MIG, TIG, and laser welding. According to a recent study by Research and Markets, systems that offer multi-process capabilities can improve productivity by up to 30%, as they reduce the need for manual setup changes between projects. Additionally, real-time monitoring and reporting tools are becoming increasingly important, enabling companies to track performance metrics and minimize downtime, which can account for up to 20% of operational costs in manufacturing environments. Adopting systems with these advanced features is essential for staying competitive in the rapidly evolving landscape of robotic welding.

This bar chart illustrates the efficiency ratings of the top 10 robotic welding systems for 2023. The ratings range from 0 to 100, highlighting their effectiveness in manufacturing processes.

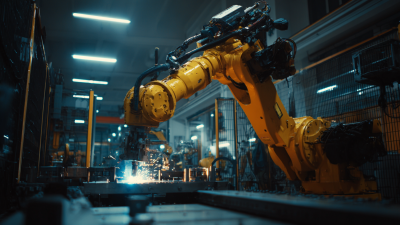

The manufacturing landscape in 2023 is undergoing a transformative shift, primarily driven by advancements in robotic welding systems that significantly enhance operational efficiency. With increasing industrialization, particularly in emerging markets, the adoption of automation technologies is accelerating. Robotic welding systems are at the forefront of this evolution, offering precision, speed, and consistency that manual processes cannot match. The integration of artificial intelligence into these systems further boosts their capabilities, enabling adaptive automation and flexibility in various manufacturing settings.

Collaborative robots, or cobots, are particularly noteworthy as they reshape flexible manufacturing environments. These robots work alongside human operators, enhancing productivity while maintaining safety and efficiency. The shift towards more intelligent and adaptive robotic systems is not only improving throughput but also optimizing resource utilization. As industries continue to embrace these innovative solutions, the focus on efficient robotic welding systems will play a crucial role in maintaining competitive advantage in the market.

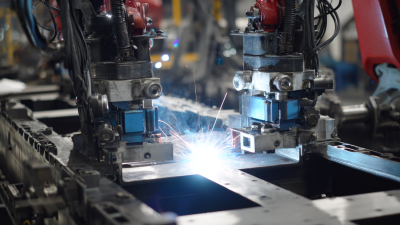

In the fast-evolving landscape of manufacturing, robotic welding systems play a crucial role in enhancing productivity and precision. This article explores a comparison of leading robotic welding brands and models available in 2023. Industry giants like FANUC, ABB, and KUKA continue to dominate the market, each offering unique features tailored for various applications. FANUC’s arc welding robots are equipped with advanced sensors, allowing for greater accuracy, while ABB’s models are renowned for their flexibility and speed, making them ideal for high-volume production.

Tips for choosing the right robotic welding system include assessing your specific production needs, including the types of materials and weldments you will be working with. Additionally, consider the level of automation required and the ease of programming the system. KUKA models, for instance, provide user-friendly interfaces that can significantly reduce training time for operators.

Another essential factor is the support and service provided by the manufacturer. A strong after-sales support system can make a significant difference in minimizing downtime. Brands that offer comprehensive training and responsive technical support, like Yaskawa, can enhance your operational efficiency, ensuring your welding operations run smoothly even during unexpected challenges.

The landscape of robotic welding is evolving rapidly, driven by advancements in artificial intelligence and automation technologies. In 2023, we can expect increased integration of machine learning algorithms that enable robotic systems to adapt to various welding conditions, improving both efficiency and accuracy. This shift towards smart welding systems allows for real-time adjustments, minimizing errors and reducing material waste.

Tips: When selecting a robotic welding system, consider its compatibility with existing manufacturing processes. Ensuring seamless integration can significantly enhance productivity and reduce downtime. Additionally, investing in training for your workforce will optimize the operation of these advanced systems.

As industries focus on sustainability, emerging trends like energy-efficient welding practices are gaining traction. Robotic systems are now being designed to consume less energy while maintaining high performance levels. This not only contributes to decreased operational costs but also aligns with corporate social responsibility goals aimed at reducing environmental impact.

Tips: Keep an eye on developments in energy-efficient technologies. Regularly updating your systems can lead to improved performance while adhering to sustainability goals, ensuring your manufacturing operations remain competitive in an increasingly eco-conscious market.

Contact Us

Pemamek Ltd