In the ever-evolving field of engineering, mastering the intricacies of pipe fabrication is essential for ensuring the efficiency and reliability of piping systems. As John Smith, a renowned expert in the pipe fabrication industry, aptly stated, "Effective pipe fabrication is not just about the assembly of materials but about crafting the very backbone of industrial infrastructure." This statement underscores the significance of understanding various techniques that can enhance productivity and reduce costs in any engineering project.

Pipe fabrication encompasses a wide range of processes, each with its own unique challenges and requirements. Engineers must familiarize themselves with the top techniques of pipe fabrication to stay competitive and deliver high-quality results. From efficient cutting to precise welding methods, each fabrication technique plays a crucial role in the successful completion of piping systems, affecting both performance and safety.

As we delve into the top 10 pipe fabrication techniques every engineer should know, it becomes clear that a solid foundation in these practices not only streamlines operations but also mitigates risks associated with improper installations. Ultimately, the effectiveness of a piping project hinges on the expertise and adaptability of the engineers involved, making their knowledge of pipe fabrication techniques indispensable.

Pipe fabrication is a crucial aspect of engineering, serving as the backbone for various industrial processes. Understanding the techniques involved in pipe fabrication equips engineers with the necessary skills to ensure efficiency, safety, and quality in their projects. Techniques such as cutting, bending, welding, and joining pipelines are foundational, each requiring a specific set of skills and tools. Mastering these processes enables engineers to design systems that are both functional and resilient, catering to the demands of different industries.

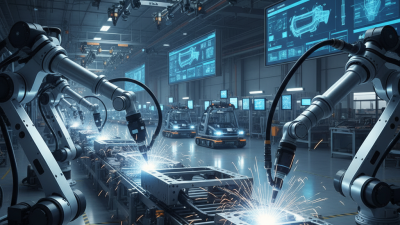

Moreover, advanced fabrication techniques such as automated welding and prefabrication are revolutionizing how pipelines are constructed. Through automation, precision is enhanced, and the likelihood of human error is reduced, leading to higher quality installations. Prefabrication allows sections of piping to be assembled in controlled environments, minimizing on-site assembly time and improving safety. As the engineering landscape continues to evolve, staying abreast of these advanced techniques is vital for engineers looking to enhance productivity and maintain competitive advantages in their fields. Understanding and applying these diverse fabrication methods can result in significant improvements in the performance and longevity of piping systems.

In the realm of pipe fabrication, selecting the appropriate materials is a critical factor that influences the overall quality, performance, and durability of the final product. Engineers must understand the specific properties of various materials, such as carbon steel, stainless steel, and plastic composites, to make informed decisions that align with the operational demands of the project. For instance, carbon steel is often favored for its strength and cost-effectiveness in high-pressure environments, while stainless steel provides superior corrosion resistance, making it suitable for applications in chemical processing and food handling.

Moreover, it's essential to consider factors such as temperature, pressure, and environmental conditions when selecting materials. The thermal expansion characteristics of different materials can affect the integrity of pipe systems, particularly in extreme temperature variations. Additionally, compatibility with the transported fluid is paramount; reactive substances may necessitate the use of special coatings or alternative materials to prevent degradation. By prioritizing these material considerations, engineers can ensure that their pipe fabrication techniques not only meet practical requirements but also enhance the longevity and reliability of their pipelines.

| Technique | Description | Key Material Considerations |

|---|---|---|

| Welding | Joining two pieces of pipe using heat to melt and fuse the edges together. | Material thickness, type of welding filler, and base material compatibility. |

| Bending | Shaping pipe into curves without compromising structural integrity. | Pipe material, bend radius, and wall thickness. |

| Cutting | Reducing pipe to the desired length using various cutting tools. | Material type, thickness, and cut precision. |

| Flanging | Creating a flange connection to join pipes with bolts. | Material compatibility, thickness, and flange design. |

| Threading | Making helical grooves for screw connections on pipes. | Material ductility and pipe diameter. |

| Coating | Applying protective layers to enhance durability and corrosion resistance. | Coating material compatibility and thickness. |

| Testing | Ensuring integrity through methods like hydrostatic or pneumatic testing. | Material strength and testing pressure requirements. |

| Inspection | Assessing materials and welds for compliance with standards. | Quality assurance systems and material certifications. |

| Assembly | Combining various pipe components together into a complete system. | Material compatibility and assembly method. |

In the field of pipe fabrication, having the right tools and equipment is crucial for ensuring precision and efficiency in every project. Essential tools include pipe cutters, which allow for clean and accurate cuts on various pipe materials, minimizing the risk of damage and ensuring a proper fit. Additionally, beveling machines play a significant role in preparing pipe edges for welding, creating the necessary grooves for strong joints. Having access to power tools such as electric drills and grinders can streamline the process, enabling engineers to perform tasks with greater speed and accuracy.

Beyond basic cutting and shaping tools, measuring instruments are vital for achieving precise results. Tools like calipers and laser measurement devices ensure that dimensions are spot-on, which is critical in the tight tolerances often required in engineering projects. Furthermore, welding equipment, including MIG and TIG welders, is indispensable for joining pipe sections together securely.

Safety equipment, such as gloves, helmets, and respirators, should also not be overlooked, as they protect engineers from hazardous conditions during fabrication. Investing in high-quality, reliable tools not only enhances performance but also contributes to the longevity of completed projects.

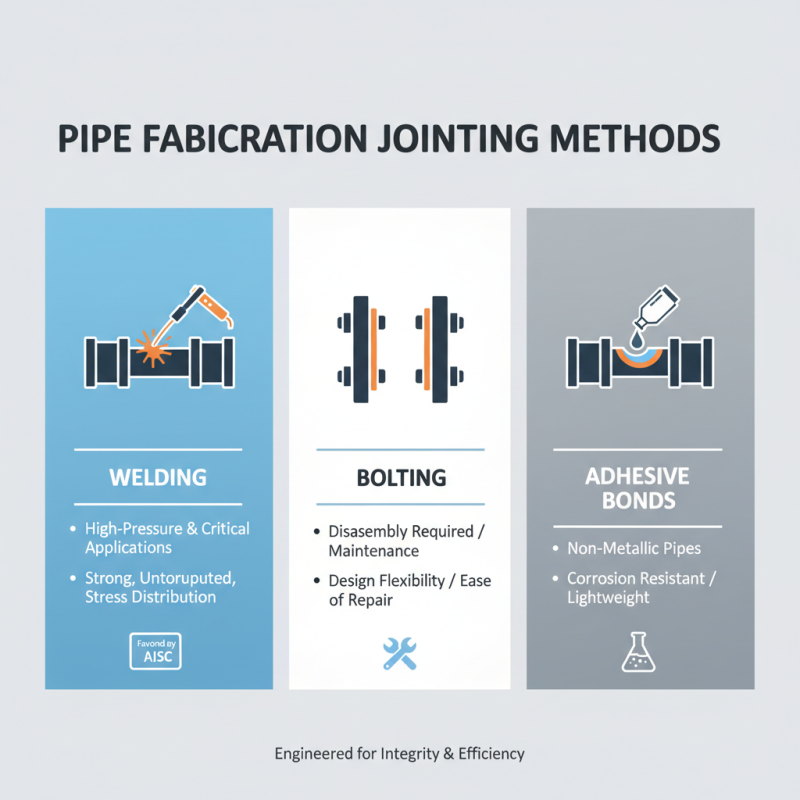

When it comes to pipe fabrication, understanding various jointing methods is crucial for engineers to ensure the structural integrity and efficient functioning of piping systems. The most common jointing methods include welding, bolting, and the use of adhesive bonds. According to a report by the American Institute of Steel Construction, welded joints are favored in high-pressure and critical applications due to their strong, uninterrupted nature, effectively distributing stresses across the entire joint area. In contrast, bolted connections are often employed in situations where disassembly is necessary, with the added benefit of ease of maintenance and flexibility in design.

In recent studies, it has been observed that the choice of jointing method can significantly impact the overall cost and durability of piping systems. For example, the International Pipe and Piping Association found that, while adhesive bonding might seem a cost-effective option for non-critical applications, it only demonstrates optimal performance in environments where low thermal expansion and chemical resistance are required. Understanding the characteristics and applications of each method helps engineers make informed decisions, ultimately leading to improved reliability and longevity of piping systems. This knowledge is essential not just for compliance with industry standards but also for optimizing operational efficiency and performance.

Quality control is a critical component of pipe fabrication processes, ensuring that the final products meet stringent industry standards and specifications. According to a report by the American Welding Society, about 30% of welding defects can be attributed to inadequate quality control measures. Implementing systematic inspection methods at various stages of the fabrication process can significantly mitigate these risks. Techniques such as visual inspections, non-destructive testing (NDT), and mechanical testing provide engineers with valuable insights into potential defects early on, ultimately reducing rework costs and enhancing overall safety.

Moreover, adherence to quality assurance protocols not only ensures compliance with industry regulations but also promotes operational efficiency. For instance, the National Institute of Standards and Technology found that organizations that embraced quality management practices saw productivity improvements of up to 25%. By integrating consistent quality assessments during material selection, fabrication, and final inspections, engineers can enhance the reliability and longevity of the piping systems constructed. Strategic investments in training personnel on these quality control measures are equally essential, as a well-trained workforce is more adept at identifying and addressing quality issues before they escalate.

Contact Us

Pemamek Ltd