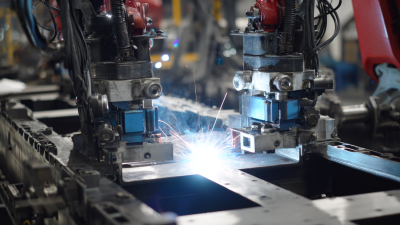

In the rapidly evolving landscape of modern manufacturing, automation stands as a pivotal force driving efficiency and precision. Among the numerous innovations in this sector, the robotic welding arm has emerged as a game-changer, revolutionizing the way welding processes are conducted. According to a recent report by the International Federation of Robotics, the global market for robotic welding solutions is projected to experience significant growth, anticipated to reach $7.6 billion by 2025, with a compound annual growth rate (CAGR) of 12.9%. This data underscores the increasing reliance of manufacturers on advanced robotic technologies to enhance productivity and reduce operational costs.

Experts in the field have recognized the profound impact that robotic welding arms have on safety and quality control in manufacturing environments. Dr. Sarah Johnson, a leading authority in robotics innovation, notes, “The integration of robotic welding arms not only minimizes human error but also ensures a consistent quality standard across production lines.” This sentiment echoes the broader industry understanding that adopting robotic solutions can lead to substantial improvements in manufacturing outcomes. As we explore the top ten advantages of utilizing robotic welding arms, it becomes clear that they are not merely a trend but essential tools for businesses aiming to thrive in today’s competitive market.

The benefits of enhanced precision in robotic welding are transforming modern manufacturing processes. Robotic welding arms offer unparalleled accuracy, which significantly reduces the likelihood of defects and rework. This precision leads to improved product quality and consistency, essential factors in competitive industries. The shift towards automation in welding also results in faster production times, enabling manufacturers to meet increasing demand without compromising quality.

Tips for enhancing precision with robotic welding include investing in advanced robotic systems equipped with sophisticated sensors and vision technology. These tools allow for real-time monitoring and adjustments, ensuring welds are made with the utmost accuracy. Additionally, regular calibration and maintenance of the robotic arms are crucial for sustaining precision over time.

Moreover, implementing simulation software can aid in planning and optimizing welding processes before physical execution. This pre-emptive step allows manufacturers to identify potential issues and refine techniques, ultimately leading to more efficient operations. Embracing these strategies can maximize the benefits of robotic welding, positioning companies for growth in the rapidly expanding market.

The integration of robotic welding arms into modern manufacturing processes has shown remarkable improvements in production efficiency. According to a report from the International Federation of Robotics (IFR), the global stock of industrial robots increased by 12% in 2021, with welding being one of the leading applications. Robotic welding arms can operate continuously without fatigue, resulting in a significant reduction in cycle times. For instance, companies adopting these technologies have reported up to a 30% increase in productivity due to faster welding speeds and reduced downtime associated with manual labor.

Moreover, a study by Deloitte highlights that manufacturers utilizing robotic welding can achieve up to 50% cost savings in labor and material wastage. The precision of robotic arms minimizes errors and rework, which are common pitfalls in traditional welding methods. These innovations also allow for greater flexibility in production lines, enabling manufacturers to switch between different welding tasks without extensive retooling. As a result, businesses can respond more swiftly to market demands, enhancing their competitive edge in an increasingly fast-paced environment.

In modern manufacturing, the adoption of robotic welding arms has become a game changer, particularly in reducing labor costs through automation. These advanced machines are capable of performing welding tasks with precision and speed, significantly lowering the need for manual labor. By minimizing human involvement in repetitive and dangerous tasks, companies can streamline their operations and ensure a safer work environment, leading to decreased employee-related expenses such as training, benefits, and insurance.

Moreover, as robotic welding arms can operate continuously without breaks, manufacturers experience increased productivity and consistency in their output. The result is not only cost savings but also enhanced product quality. The scalability of automation means businesses can adjust production levels with ease to meet fluctuating demand without the overhead associated with hiring and training additional staff. In this way, the integration of robotic welding technology is not just a step forward in efficiency; it represents a strategic shift towards a more economically viable manufacturing landscape.

| Advantage | Description | Estimated Cost Savings (%) |

|---|---|---|

| Increased Efficiency | Robotic welding arms operate at a consistent speed, reducing the time taken for welding tasks. | 30% |

| Higher Precision and Quality | Robots provide higher accuracy, leading to better join quality and fewer defects. | 25% |

| Reduced Labor Costs | Automation cuts the need for manual labor, saving on salaries and training. | 40% |

| Improved Workplace Safety | Fewer workers in hazardous environments decreases the risk of accidents. | 20% |

| Ability to Work in Harsh Environments | Robots can operate in extreme temperatures or hazardous settings without human risks. | 15% |

| Consistent Production Rates | Robotics ensure uniform production quality and quantity across shifts. | 35% |

| Flexibility in Production | Robots can be reprogrammed for different tasks, allowing for quick adaptations to changes. | 10% |

| Data Collection and Analysis | Robots can gather operational data, helping improve the manufacturing process. | 5% |

| Reduced Waste | Higher precision leads to less material waste during the welding process. | 20% |

| Enhanced Customization | Robots can be programmed for custom welding patterns, accommodating varied client demands. | 10% |

The integration of robotic welding solutions in modern manufacturing significantly enhances workplace safety, addressing a critical concern in industrial environments. By employing robotic arms for welding tasks, manufacturers can minimize human exposure to hazardous conditions such as extreme heat, toxic fumes, and dangerous equipment. This shift not only protects workers but also contributes to a notable reduction in workplace injuries, fostering a more secure working environment.

As the global robotic welding market is expected to grow from $8.1 billion in 2025 to $20.16 billion by 2032, the rapid adoption of automation and AI technology highlights the trend toward safer and more efficient production processes. In the automotive sector, for instance, precision molds and consistent weld quality can be achieved through robotic systems, ultimately enhancing operational efficiency. With the ongoing advancements associated with Industry 4.0, manufacturers are better positioned to leverage these innovations, ensuring that safety remains a top priority while elevating productivity levels across the board.

In modern manufacturing, the

flexibility and adaptability of robotic welding systems play a crucial role in enhancing

production efficiency. These advanced systems can be easily programmed to accommodate various projects, allowing manufacturers to switch tasks without significant downtime. This capability not only improves workflow but also enables companies to respond swiftly to changing market demands, ensuring that they can adapt their output to meet customer needs more effectively.

Tips for leveraging the flexibility of robotic welding arms include programming them for multiple tasks, which can streamline the setup process for different products. Additionally, regular calibration and maintenance of the robotic systems ensure consistent performance across various applications. Manufacturers should also invest in training their staff to utilize these advanced machines to their full potential, enabling them to take advantage of the system's adaptability.

Moreover, robotic welding systems can be easily

integrated with other manufacturing technologies. This interoperability allows for seamless operations within automated production lines, providing manufacturers the agility needed to innovate and maintain a competitive edge. By embracing the adaptability of robotic welding arms, companies can maximize their production capabilities while minimizing costs.

Contact Us

Pemamek Ltd