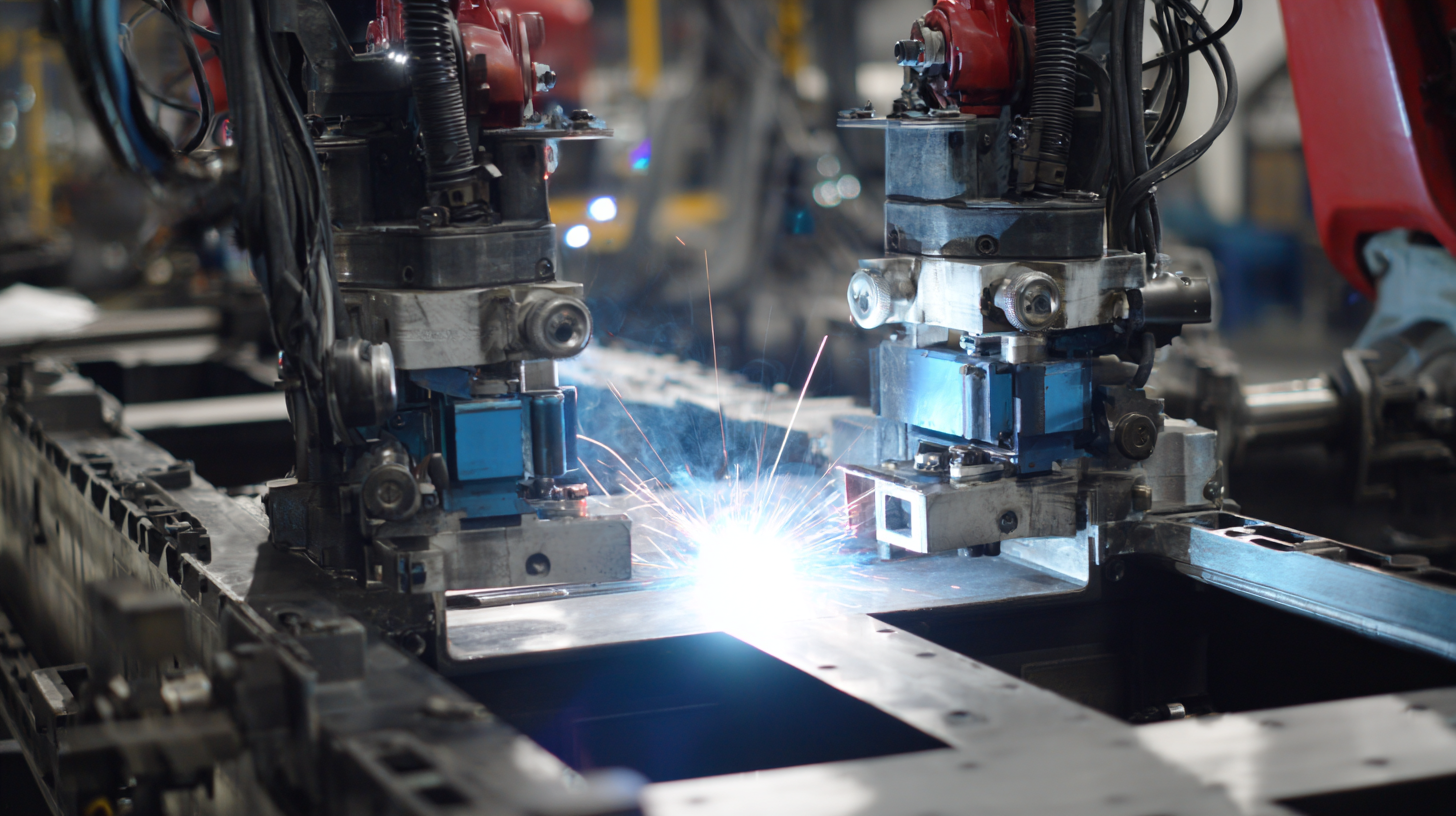

In the ever-evolving landscape of manufacturing and fabrication, the need for efficiency and precision has never been more critical. Welding manipulators have emerged as indispensable tools that streamline the welding process, ensuring optimal results while maximizing productivity. As we look ahead to 2025, the integration of advanced technologies within welding manipulators is set to transform the way industries approach fabrication tasks.

This article delves into the top five welding manipulators that can significantly enhance your fabrication efficiency. Each of these innovative devices reflects the latest advancements in automation, ergonomics, and versatility, catering to a diverse range of welding applications. By adopting these key technologies, businesses can not only improve their operational workflows but also ensure superior quality in their finished products.

Join us as we explore the features, benefits, and potential impact of these top welding manipulators in modern fabrication settings. Whether you are a seasoned fabricator or just starting in the industry, understanding the role of these tools can empower you to elevate your operations to new heights.

Welding manipulators play a crucial role in modern fabrication processes, significantly improving both efficiency and precision. According to the American Welding Society, effective use of manipulators can enhance productivity by up to 25%, allowing for better control over weld placement and reducing the potential for human error. With the industry's growing demand for high-quality welds, the integration of advanced manipulators is becoming essential in achieving optimal outcomes.

Welding manipulators play a crucial role in modern fabrication processes, significantly improving both efficiency and precision. According to the American Welding Society, effective use of manipulators can enhance productivity by up to 25%, allowing for better control over weld placement and reducing the potential for human error. With the industry's growing demand for high-quality welds, the integration of advanced manipulators is becoming essential in achieving optimal outcomes.

In addition to boosting productivity, welding manipulators also contribute to worker safety. According to the National Institute for Occupational Safety and Health (NIOSH), improper welding posture and fatigue account for a significant percentage of workplace injuries in fabrication environments. By employing manipulators, businesses can ensure that welders maintain proper posture and minimize the risk of injury, leading to a more sustainable workforce. As these technologies continue to evolve, manufacturers are increasingly recognizing the need to invest in modern welding manipulators to enhance both operational efficiency and worker safety, ultimately driving the industry's growth forward.

When selecting a welding manipulator, it's essential to focus on key features that will enhance fabrication efficiency. The latest advancements highlight the integration of intelligent control systems, such as fuzzy-particle swarm optimization, which optimizes robotic arm operations in welding applications. This technology allows for greater precision and adaptability, making it invaluable in modern manufacturing settings.

One crucial feature to consider is the manipulator's range of motion. A versatile welding manipulator should offer multiple axes of movement, allowing welders to access intricate and hard-to-reach areas. Additionally, the speed and accuracy of the movement directly impact productivity levels—efficiency can be increased by up to 40% with the right manipulator. Another vital aspect is the controller used for operation; investing in sophisticated controllers, like fuzzy DC linear servo controllers, can significantly enhance the performance of the welding manipulator.

Tips:

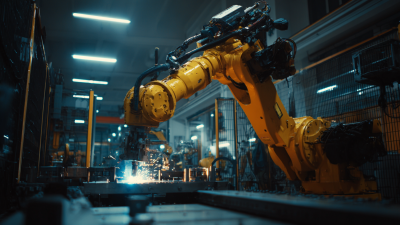

In 2025, the welding industry continues to evolve, driven by technological advancements that enhance fabrication efficiency. A comparative analysis of the top five welding manipulators reveals significant differences in design, functionality, and user experience. Manufacturers have focused on creating manipulators that not only meet the diverse needs of modern fabrication environments but also improve productivity and safety.

The analysis highlights key features such as precision control, ease of operation, and integration with automated systems. For instance, some models offer advanced robotics capabilities, allowing for complex welding tasks with minimal operator intervention. Additionally, the ergonomic designs of the manipulators contribute to reducing operator fatigue, enhancing overall work efficiency. By comparing these attributes, fabricators can make informed decisions, choosing the best equipment that aligns with their operational goals while maximizing return on investment.

Furthermore, attention to the adaptability of these manipulators to various welding techniques, such as MIG, TIG, and submerged arc welding, is crucial. The top five models in 2025 showcase a remarkable ability to switch between processes seamlessly, ensuring that fabricators can tackle a wide range of projects with precision and speed. Therefore, understanding the comparative strengths of each manipulator is essential for businesses aiming to enhance their fabrication capabilities.

This chart compares five different welding manipulators based on their maximum load capacity, arm reach, and efficiency rating. The data reflects how these factors contribute to overall fabrication efficiency in a welding environment.

In modern fabrication environments, safety is paramount, and welding manipulators play a crucial role in enhancing this aspect. These machines not only streamline the welding process but also significantly reduce the risk of accidents and injuries. By providing precise control and positioning of heavy materials, welding manipulators minimize the need for workers to handle cumbersome components, thus lessening the likelihood of strains or other physical injuries. This improved ergonomics translates to a safer workplace, where operators can focus on their tasks without the constant threat of injury from lifting and maneuvering heavy objects.

Tips for enhancing safety with welding manipulators include ensuring regular maintenance and inspection of the equipment. Keeping the manipulators in optimal condition not only prolongs their lifespan but also ensures reliable performance during critical tasks. Furthermore, providing comprehensive training for operators is essential. They must understand how to use these machines correctly, recognize potential hazards, and follow best practices to maintain a safe working environment. Always emphasize the importance of personal protective equipment (PPE) while operating welding manipulators, as this serves as a first line of defense against unexpected accidents.

Incorporating these strategies can lead to a significant improvement in safety standards within fabrication environments, fostering a culture of safety and efficiency.

| Manipulator Model | Max Load Capacity (lbs) | Reach (inches) | Safety Features | Application Suitability |

|---|---|---|---|---|

| Model A | 2000 | 48 | Overload protection, emergency stop | Heavy duty welding, fabrication |

| Model B | 1500 | 36 | Auto shut-off, safety guard | Pipeline construction, assembly |

| Model C | 2500 | 60 | Tilt sensors, reinforced lift straps | Shipbuilding, structural steel |

| Model D | 1000 | 30 | Emergency braking, warning lights | Light welding, light fabrication |

| Model E | 1800 | 54 | Safety lock, pressure monitoring | General fabrication, automotive |

In the competitive landscape of fabrication, investing in advanced welding manipulators can yield significant returns on investment (ROI) while enhancing operational efficiency. These sophisticated machines are designed to optimize the welding process, reduce manual labor, and minimize errors, ultimately leading to faster production cycles and improved product quality. By automating tasks that were once time-consuming and labor-intensive, businesses can redirect their workforce toward higher-value activities, effectively leveraging their human resources.

When considering the integration of welding manipulators, it's crucial to assess the specific needs of your operation. Tip: Evaluate your current workflow to identify bottlenecks that automation could alleviate. This will help you choose a manipulator model that aligns with your production goals. Additionally, investing in training for your team on the new technology can enhance adoption rates and maximize efficiency gains.

Another important aspect is the adaptability of welding manipulators. Tip: Look for systems that offer customizable features to accommodate various welding processes and materials. This flexibility will ensure that your investment remains beneficial as your project demands evolve over time, providing sustained efficiency improvements and ROI well into the future.

Contact Us

Pemamek Ltd