In the world of welding, the efficient handling of cylindrical and large workpieces is crucial for successful projects. Turning rolls are essential tools that facilitate this process, enabling welders to achieve precision and stability during their tasks. As noted by industry expert John Smith, "The introduction of turning rolls has transformed the way we approach welding projects, offering unparalleled support and control." This statement underscores the importance of integrating turning rolls into various welding applications, ensuring that the process is not only efficient but also safe.

When working with heavy materials, the right tools can make all the difference. Turning rolls streamline the rotation of workpieces, allowing for improved access to weld seams while minimizing physical strain on the welder. As we dive into the top ten tips for effectively utilizing turning rolls in your welding projects, it's essential to understand the various types and configurations available, as well as best practices for setup and operation. By mastering the use of turning rolls, welders can enhance their craftsmanship and tackle even the most challenging projects with confidence.

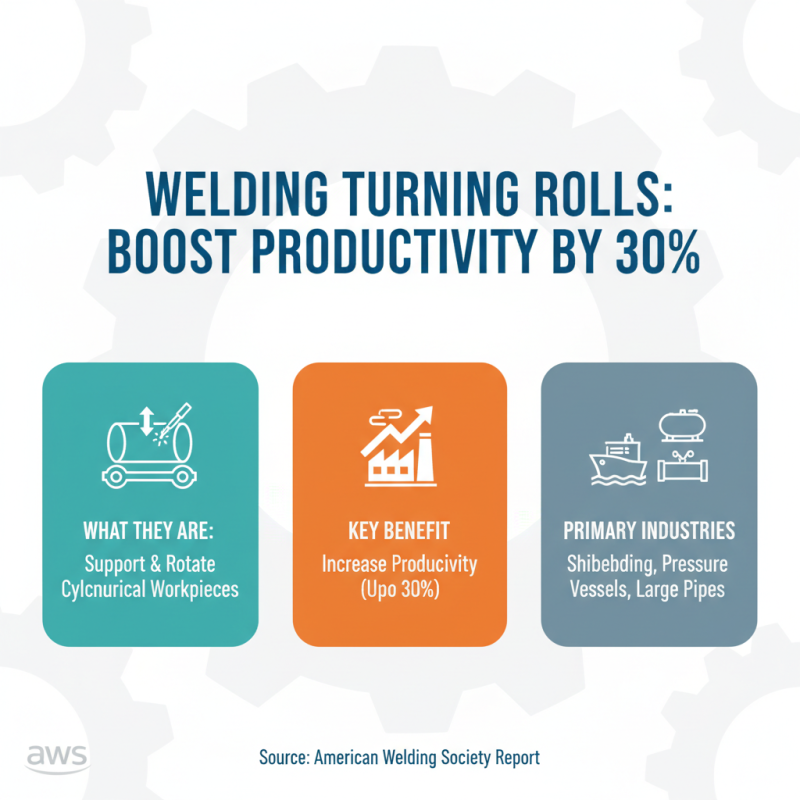

Turning rolls are an essential piece of equipment in welding applications, specifically designed to handle cylindrical or large workpieces. Understanding the basics of turning rolls can significantly enhance the efficiency and precision of your welding projects. According to a report by the American Welding Society, the use of turning rolls can increase productivity by up to 30%, making them a vital component in industries such as shipbuilding, pressure vessel construction, and large-scale piping systems.

Turning rolls operate by rotating the workpiece, allowing the welder to maintain a consistent angle and improve weld quality. This capability is crucial as it minimizes the risk of improper welds that can lead to structural failures. The positioning and rotation provided by turning rolls enable a welder to focus on technique, as well as aid in achieving uniform heat distribution. Reports indicate that this can reduce the overall time spent on projects and help maintain strict component specifications, crucial in industries that require high standards such as aerospace and automotive manufacturing. Understanding these benefits can help welders make informed choices about integrating turning rolls into their workflow for optimal results.

When selecting turning rolls for your welding projects, several key factors must be taken into consideration to ensure optimal performance and efficiency. The weight capacity of the turning rolls is paramount; according to the American Welding Society, turning rolls can accommodate loads ranging from a few hundred pounds to several tons. Therefore, it is crucial to match the load capacities of the rolls with the specifications of your workpieces to avoid compromising safety and effectiveness.

Another important factor is the adjustability of the turning rolls. Models that provide adjustable centers and various diameter options offer greater versatility, accommodating different workpiece sizes and shapes. Research from the Welding Equipment Manufacturers Association suggests that investing in adjustable turning rolls can enhance productivity by up to 30%, as they allow for quick setup changes between projects. Additionally, consider the type of drive system; driven turning rolls provide better control and speed consistency, which is critical for achieving uniform welds on cylindrical components. By taking these considerations into account, you can significantly improve the outcomes of your welding projects.

| Tip Number | Key Factor | Description | Considerations |

|---|---|---|---|

| 1 | Load Capacity | Ensure the turning rolls can handle the weight of your workpiece. | Check specifications for maximum load limits. |

| 2 | Roll Diameter | Select the appropriate roll diameter for your application. | Consider the diameter of your workpieces. |

| 3 | Speed Control | Look for adjustable speed settings for different materials. | Evaluate the type of welding process being used. |

| 4 | Material Quality | Choose turning rolls made from durable materials. | Assess the environmental conditions of your workspace. |

| 5 | Adjustability | Find turning rolls that offer adjustability to accommodate different sizes. | Consider the variety of projects you typically handle. |

| 6 | Safety Features | Incorporate safety features such as emergency stops. | Review safety practices in your work environment. |

| 7 | Portability | Consider the ease of movement for your turning rolls. | Assess the layout of your workshop. |

| 8 | Cost | Evaluate your budget against turning roll features. | Balance quality with affordability. |

| 9 | Brand Reputation | Research trusted brands known for quality welding equipment. | Read user reviews and testimonials. |

| 10 | Maintenance | Understand maintenance needs to extend the lifespan of your rolls. | Follow manufacturer guidelines for upkeep. |

When setting up turning rolls for welding tasks, the first step is to ensure that the rolls are positioned correctly to accommodate the specific dimensions of the workpiece. Proper alignment is crucial; the rolls should be parallel and level to prevent any misalignment during the rotation of the workpiece. This alignment not only enhances the welding process but also contributes to the overall safety of the operation. It is advisable to measure the diameter of the workpiece and adjust the rolls accordingly, allowing for enough clearance for the welding torch and other necessary tools.

Another best practice is to secure the workpiece firmly on the rolls before starting the welding process. Utilizing clamps or fixtures can help stabilize the item, reducing vibrations and unwanted movements that could affect weld quality. Additionally, operators should ensure that the turning rolls are maintained in optimal condition; regular inspections and lubrication of the rollers can prevent operational failures and enhance performance. It’s also beneficial to familiarize oneself with the weight capacity of the turning rolls to avoid overloading, which could lead to accidents and equipment damage.

The following bar chart illustrates the effectiveness of various best practices for setting up turning rolls in welding tasks based on user feedback.

When working with turning rolls in welding projects, safety should always be your top priority. Before initiating any welding operation, it is essential to inspect the turning rolls for any signs of wear or damage. Check the power cables and controls to ensure they are in proper working condition. Additionally, ensure that the work area is clean and free of any hazards that could impede movement or create obstacles. Using turning rolls effectively requires familiarity with the equipment, so operators should receive thorough training on both the setup and the operational procedures.

Personal protective equipment (PPE) plays a vital role in maintaining safety during welding operations. Always wear welding helmets, gloves, and appropriate clothing to protect against sparks and intense heat. Clear communication among team members is also essential; establish hand signals or use communication devices to manage operations safely.

Furthermore, ensure that the turning rolls are operated at the correct speed for the material being welded. Overexerting the rolls or working outside recommended guidelines can lead to accidents and injuries. By adhering to these safety guidelines and precautions, welders can significantly reduce the risks associated with using turning rolls in their projects.

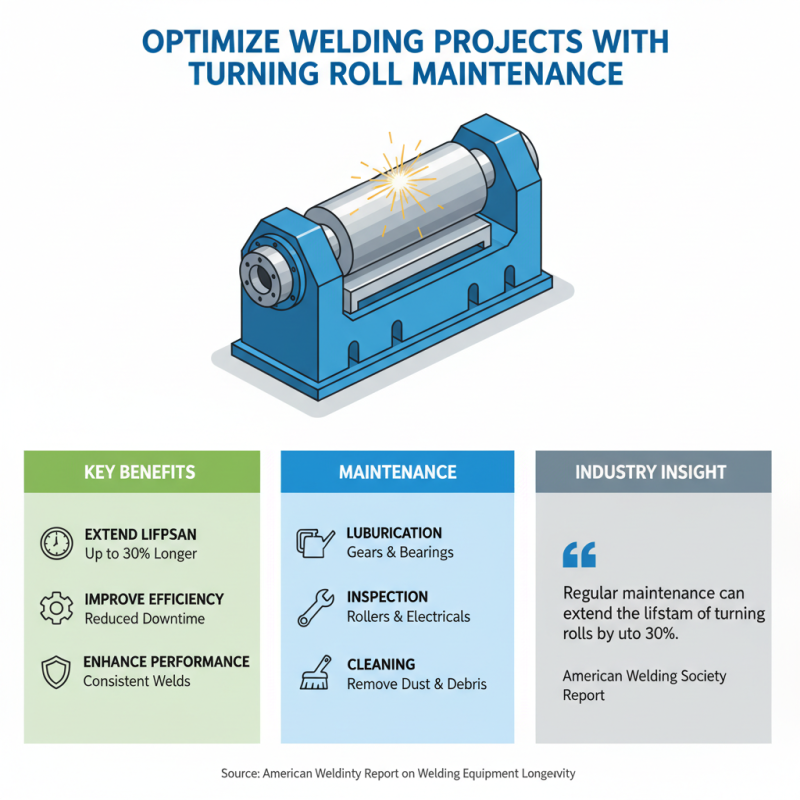

Turning rolls are essential tools for welding projects, especially when working with large cylindrical workpieces. Proper maintenance of these machines is crucial for ensuring their longevity and performance. According to a report from the American Welding Society, regular maintenance can extend the lifespan of turning rolls by up to 30%, significantly improving their efficiency and reducing downtime.

One key maintenance tip is to consistently check and adjust the alignment of the rollers. Misalignment can lead to uneven wear and affect the quality of your welds. It is advisable to perform these checks on a weekly basis or more frequently if the machine is used heavily. Additionally, regular lubrication of all moving parts is vital to prevent friction and wear, which can compromise performance. The National Institute for Occupational Safety and Health recommends maintaining a detailed log of maintenance activities, allowing operators to track performance trends and identify any recurring issues.

Another important aspect of maintaining turning rolls is to keep the work area clean and free of debris. Accumulated dirt and spatter can interfere with the operation of the rolls, leading to accidents or equipment malfunction. Implementing a cleaning schedule every day can significantly enhance overall safety and operational performance. Moreover, training operators on the best practices for using turning rolls can further ensure that these vital tools remain in optimal condition for all welding projects.

Contact Us

Pemamek Ltd