Choosing the right pipe welding positioner is crucial for efficient fabrication. A high-quality positioner can enhance precision and reduce operator strain. This equipment holds pipes securely in various welding angles. It allows welders to work comfortably, limiting fatigue and ensuring consistent results.

When selecting a pipe welding positioner, consider key factors. Weight capacity is essential. You don’t want a positioner that can’t handle the materials you use. Look for versatility in movement. It should adapt to different project requirements without complicated adjustments. Attention to detail can be the difference between a successful weld and a poor one.

Reflecting on your own workflow may reveal needs you hadn’t considered. Is your current positioner causing delays? Are there features you wish you had? Investing time in choosing the right pipe welding positioner means acknowledging these areas for improvement. The right choice will elevate your workmanship to a higher standard.

In the realm of welding, pipe welding positioners play a crucial role. These tools enhance efficiency and accuracy during welding projects. According to industry reports, around 25% of welding inefficiencies stem from improper positioning. A well-chosen positioner minimizes this issue, leading to better weld quality and reduced rework.

When selecting a pipe welding positioner, consider its capacity and range of motion. Some projects may need a positioner that can handle heavy pipes, while others may require a more mobile option. The American Welding Society notes that effective positioning reduces weld defects by up to 30%. This can save significant costs and time during fabrication.

However, not all positioners are created equal. Some may lack essential features like rotation speed control. A limited range of adjustment can lead to discomfort for welders and impact overall performance. It is essential to reflect on these aspects before making a purchase. Making an informed choice can transform your project’s outcome for the better.

When selecting a pipe welding positioner, consider key features that significantly affect your project quality. A crucial aspect is the load capacity. Many reports suggest positioners with a capacity between 1,000 to 5,000 pounds are ideal for most industrial tasks. Analyze your workpiece weight before making a choice. A mismatched capacity can lead to safety hazards or equipment failure.

Another important feature is the adjustability of the positioner. A flexible range of tilt and rotation allows for better accessibility during welding. Positioners that offer 360-degree rotation and varied tilt angles can improve weld precision. Operators often struggle with fixed positions that hinder effective welding techniques.

**Tip:** Always check for compatibility with your tools. Sometimes, dimensions can be tricky. Ensure your positioner fits seamlessly with your existing welding equipment. Investing time in this detail can prevent costly adjustments later.

Price is also a factor. While some positioners may be more affordable, they often lack key features that enhance performance. Some reports show that companies save up to 30% on labor costs after investing in higher-quality positioners. Quality does matter in the long run, but it is important to reflect on what features are necessary for your specific needs.

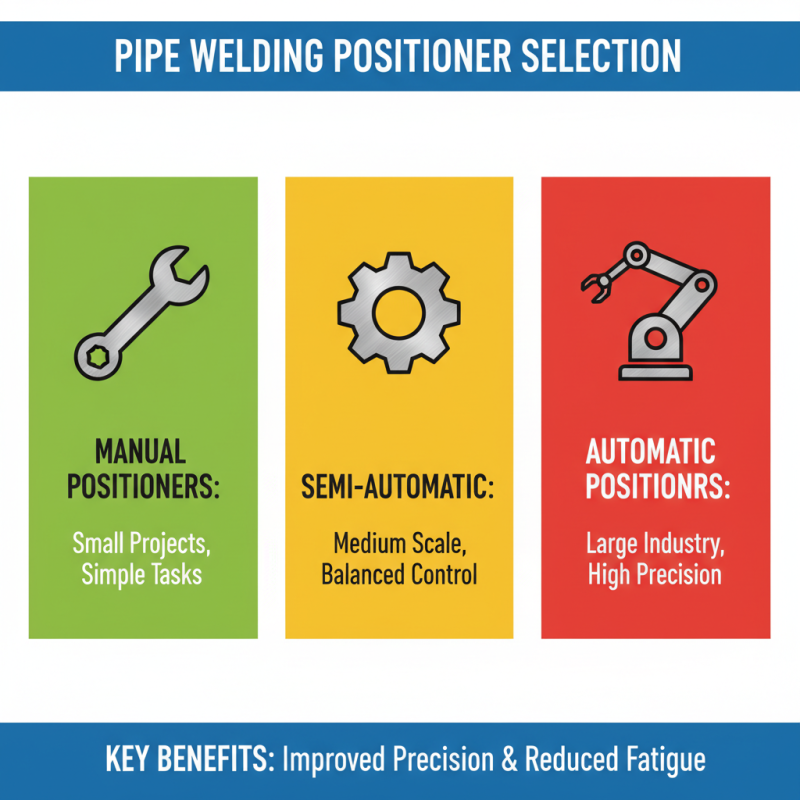

When it comes to pipe welding, selecting the right positioner is crucial. There are various types available, each suited for specific tasks. For instance, a manual positioner may be suitable for small-scale projects. However, larger industrial tasks often require automatic or semi-automatic models. These can help improve precision and reduce fatigue. Understanding these options is essential for efficiency.

Another important aspect is the application of each positioner type. A fixed positioner allows for stable welding on larger pipes. In contrast, a tilting positioner adds versatility for working on angled joints. It's worth noting that with more complex tasks, precision may falter without the right tools—this can lead to costly errors. Assessing the project scope can help avoid these pitfalls.

Moreover, the choice of a pipe welding positioner should reflect on your welding environment. Factors such as space limitations or the complexity of the workpiece matter. Sometimes, choosing a more compact model may limit functionality. Reflection is necessary; the perfect positioner for one job may not suit another. Balancing these elements can facilitate better outcomes in your welding projects.

When selecting a pipe welding positioner, understanding your project needs is vital. Each project varies in complexity and requirements. Some projects may involve large pipes, while others may focus on tighter spaces. This distinction will guide your choice of positioner.

Consider the weight capacity needed for your workpieces. A positioner with too little capacity can lead to accidents. Look for a unit that can handle your heaviest load, but also assess if it’s more than required. Over-engineering can waste resources.

Tip: Always account for the positioning range. You might need more flexibility if you work with various sizes. A positioner's ability to rotate and tilt can enhance accessibility. However, ensure it does not compromise stability. Improper balance creates risks. Reflect on your workspace layout too; when set incorrectly, positioners can be counterproductive.

Evaluate your project flow. Are there multiple welds in different positions? If so, investing in a swivel positioner could save time. But balance that need with your budget. Sometimes, simpler options can achieve similar results. Assess your actual needs first.

This bar chart illustrates critical evaluation criteria for selecting the best pipe welding positioner for various projects. Factors such as load capacity, adjustability, rotation speed, price, and durability rating are essential for making an informed choice tailored to specific project needs.

When choosing a pipe welding positioner, budgeting is crucial. The price range can vary widely. Investing too little can lead to inefficiencies. Finding a balance between cost and quality is tricky yet essential.

Consider the specific projects you have. Will you tackle large pipelines or smaller tasks? Each project might require a different level of investment. Researching used equipment can be a cost-effective solution. However, damaged or outdated models can lead to higher service costs later.

Look for features that fit your needs. A more expensive positioner may save time and resources in the long run. Evaluate long-term benefits over initial spending. Sometimes, opting for cheaper options leads to frequent replacements. Reflect on the true cost over time rather than just the sticker price.

Contact Us

Pemamek Ltd