In the realm of heavy equipment performance, tank rollers play a pivotal role in ensuring operational efficiency and durability. According to the International Association of Equipment Managers, proper maintenance and utilization of components such as tank rollers can significantly enhance the lifespan of machinery, with studies indicating that effective roller functionality can reduce equipment wear by up to 30%. These components are integral to the stability and maneuverability of heavy machinery, particularly in rugged terrains where optimal traction and support are necessary.

Moreover, tank rollers contribute greatly to the overall load distribution and weight transfer of heavy equipment, facilitating smoother operations and minimizing the risk of equipment failure. A report by the Heavy Equipment Manufacturers Association suggests that machinery with well-maintained tank rollers can achieve fuel efficiency improvements of nearly 15% over those with inadequate roller systems. This efficiency not only impacts operational costs but also contributes to a more sustainable approach within the heavy equipment industry. Therefore, understanding the essential role of tank rollers is critical for operators and businesses aiming to maximize the performance and lifespan of their heavy machinery.

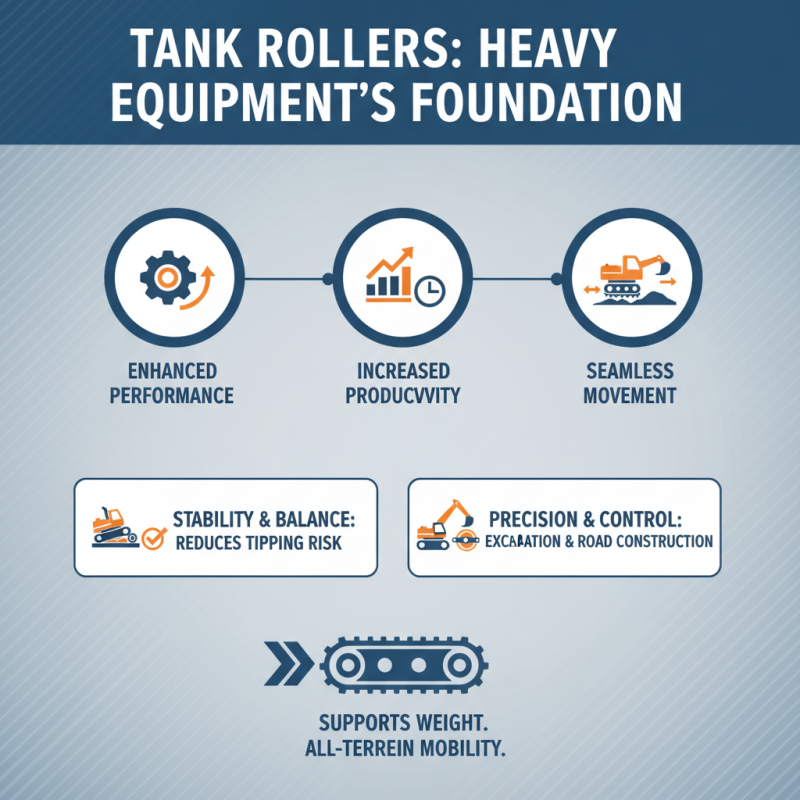

Tank rollers play a crucial role in the operation of heavy equipment, particularly in enhancing performance and increasing productivity. These components support the weight of the machine while enabling seamless movement across various terrain types. A well-functioning tank roller ensures stability and balance, reducing the risk of equipment tipping or getting stuck. This stability is vital for tasks that require precision and control, such as excavation and road construction.

Proper maintenance of tank rollers is essential to ensure their longevity and performance. Regularly checking for wear and tear and lubricating the rollers can prevent unexpected breakdowns and costly repairs. A tip to consider is to monitor the roller alignment; misaligned rollers can lead to uneven wear, impacting the overall efficiency of the machine. Additionally, keeping the rollers clean from debris and mud can also enhance performance by reducing friction, allowing for smoother operation.

Investing time in understanding the importance of tank rollers can significantly impact the operational efficiency of heavy machinery. Operators should always be aware of the condition of these critical components during daily inspections. A simple yet effective tip is to establish a routine check to verify the functionality of each roller, ensuring optimal performance and reducing the risks associated with heavy equipment operations.

Tank rollers play a critical role in the functionality and performance of heavy machinery, particularly in demanding work environments. These components are designed to support the weight of the equipment while allowing for smoother movement over rough terrains. By minimizing friction and distributing the machine’s weight effectively, tank rollers enhance the overall stability and maneuverability of the machinery, enabling operators to navigate challenging job sites with ease.

Moreover, tank rollers are essential for maintaining the longevity of heavy equipment. They absorb impacts and shocks that occur during operation, reducing wear and tear on other components of the machine. This not only helps in preserving the integrity of the equipment but also plays a vital role in improving safety on the job. When tank rollers function properly, they ensure that the machinery remains in optimal working condition, which is crucial for maximum productivity in construction, mining, and agricultural applications. Thus, understanding the functionality of tank rollers is key to appreciating their importance in heavy machinery performance.

| Aspect | Description | Impact on Performance |

|---|---|---|

| Load Distribution | Tank rollers help distribute the weight of heavy machinery evenly across the surface. | Improves stability and reduces wear on individual components. |

| Mobility | They provide mobility by allowing smooth movement over different terrain types. | Enhances operational efficiency and reduces downtime. |

| Durability | Constructed from high-strength materials to withstand heavy loads and harsh environments. | Prolongs equipment lifespan and reduces replacement frequency. |

| Maintenance | Regular maintenance is required to ensure optimal performance of rollers. | Prevents costly repairs and ensures safety during operation. |

| Compatibility | Designed to fit a variety of heavy machinery models. | Maximizes versatility and allows for seamless integration. |

The condition of tank rollers is crucial to the overall performance of heavy equipment, significantly affecting its operational efficiency. Studies indicate that worn or damaged rollers can lead to increased friction and resistance, which directly impacts fuel consumption. According to a report from the Construction Equipment Market Association, heavy machinery that experiences poor roller condition can incur an additional 10% in fuel costs over time, undermining the cost-effectiveness of operations.

Furthermore, a comprehensive analysis in the Journal of Heavy Equipment Fleet Management reveals that maintaining optimal tank roller condition can extend the lifespan of track systems by up to 30%. This prolongation reduces the need for frequent replacements and repairs, leading to both lower maintenance costs and increased uptime for equipment. Proper lubrication and regular inspections are vital practices that ensure the tank rollers perform as intended, thereby enhancing the equipment's overall productivity and reducing the likelihood of catastrophic failures that could halt operations entirely.

In essence, ensuring the health of tank rollers not only improves immediate equipment efficiency but also contributes to long-term operational savings and reliability. Heavy machinery operators who prioritize roller maintenance are more likely to see sustained performance levels and reduced operational costs over the equipment's lifespan.

Worn tank rollers on heavy equipment can lead to a cascade of performance issues, severely affecting operational efficiency and safety. According to the Equipment Maintenance Journal, approximately 30% of equipment downtime is attributed to mechanical failures, with worn or damaged rollers being a leading cause. These components are pivotal in supporting the weight of the equipment and facilitating smooth movement. When tank rollers wear down, they can cause uneven weight distribution, leading to instability during operation, which not only increases the risk of accidents but also accelerates wear on other critical components.

In addition, failing to address worn tank rollers can result in increased fuel consumption. The National Equipment Dealers Association reports that heavy equipment can consume up to 25% more fuel when not operating optimally. Dragging or misaligned rollers require more effort from the machinery to move, resulting in higher operational costs. Regular inspection and timely replacement of tank rollers are essential to prevent these common problems.

Keeping these components in good condition not only enhances the performance and safety of heavy equipment but also helps in maintaining overall machinery longevity, ultimately leading to lower repair costs and improved productivity.

Maintaining tank rollers is crucial for the optimal performance of heavy equipment. Regular inspections should be part of any maintenance routine. Operators should check for wear and tear, ensuring that the rollers are free from debris and damage. It's important to assess the surface contact and alignment of the rollers to maintain proper functioning during operation. Any signs of misalignment or excessive wear should prompt immediate attention to prevent further damage to the equipment or inefficient operation.

Another best practice involves lubrication. Keeping tank rollers well-lubricated minimizes friction, reduces wear, and helps prevent rust and corrosion. Utilizing the correct type and amount of lubricant according to manufacturer specifications can significantly extend the lifespan of the rollers. Furthermore, operators should clean the rollers frequently to remove dirt and contaminants, as these can lead to premature wear. Implementing these best practices effectively enhances the durability of tank rollers and ensures that heavy equipment operates at peak performance.

The following chart illustrates the average wear level of tank rollers for different heavy equipment types over a year. Regular maintenance is crucial to ensure optimal performance and longevity of the equipment.

Contact Us

Pemamek Ltd