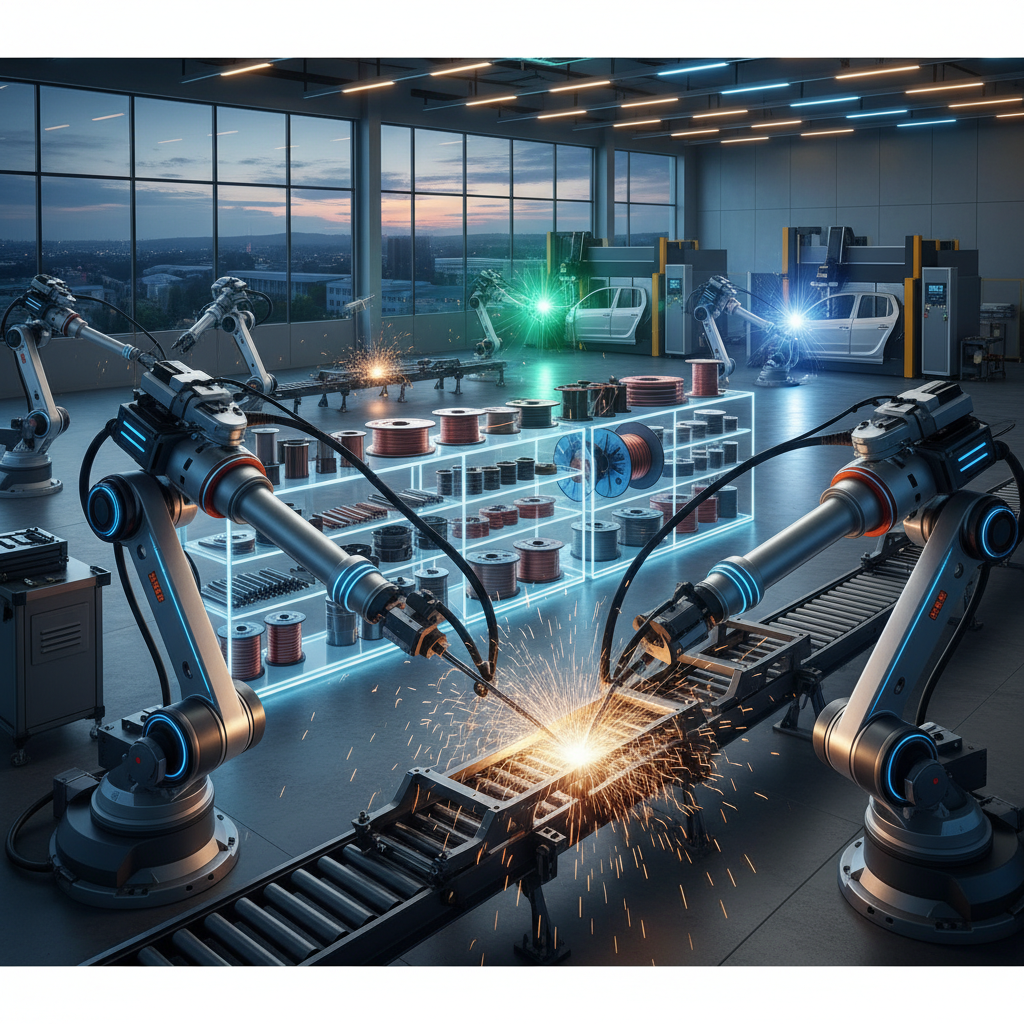

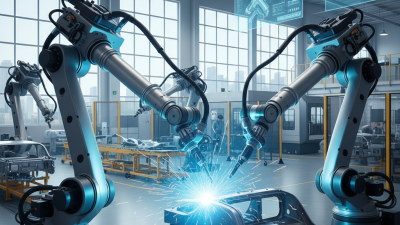

In the rapidly evolving landscape of manufacturing, the adoption of advanced technologies is crucial for maintaining competitiveness and efficiency. One such innovation is the robotic welding cell, a sophisticated solution that integrates robotic automation to enhance welding processes. Industry expert Dr. Michael Reynolds from the Robotics Institute emphasizes the transformative impact of this technology, stating, "Robotic welding cells not only improve precision and speed, but they also significantly reduce production costs and enhance safety for workers."

As manufacturers seek to streamline operations and improve product quality, the implementation of robotic welding cells becomes increasingly relevant. These systems offer unparalleled flexibility, allowing companies to adapt to varying production demands effortlessly. With the capability to execute repetitive welding tasks with high accuracy, robotic welding cells are revolutionizing traditional manufacturing approaches, making it easier for organizations to meet modern industry standards.

In conclusion, the robotic welding cell is more than just a technological advancement; it represents a fundamental shift in how manufacturing processes are approached. By leveraging automation, manufacturers can achieve greater efficiency and maintain a competitive edge in a global market characterized by rapid change and innovation.

Robotic welding cells are integral to modern manufacturing, characterized by their streamlined processes and advanced automation components. These cells typically consist of industrial robots, workstations, and automated safety systems, all orchestrated to enhance production efficiency. A recent report indicates that robotic welding systems can improve productivity by up to 30% while reducing waste and downtime significantly. In environments where skilled labor shortages are a pressing issue, these systems provide an essential solution by filling labor gaps effectively.

Moreover, advancements in smart technology within robotic welding cells are revolutionizing their functionality. For instance, innovations like friction stir welding are gaining traction, especially in sectors such as e-mobility, where high precision and strength are critical. Additionally, the introduction of flexible robotic solutions allows for multiple robots to operate within a compact space, adapting quickly to varied production demands.

According to the International Federation of Robotics, the demand for such automation in welding is projected to grow by over 20% in the coming years, highlighting the vital role robotic welding cells will play in the future of manufacturing.

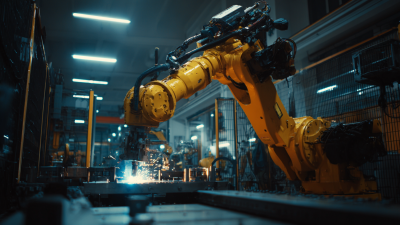

Automation has become a cornerstone of modern manufacturing processes, fundamentally transforming efficiency and productivity. According to a report by McKinsey & Company, companies that adopt automation can see productivity increases of 20% to 30%. This shift not only reduces manufacturing times but also minimizes human error, which can lead to significant savings in costs and resources. As manufacturers increasingly integrate automated systems like robotic welding cells, they are better positioned to respond swiftly to market changes and customer demands.

The global robotic welding market is projected to reach $5.97 billion by 2025, reflecting a compound annual growth rate (CAGR) of 7.9% from 2020. This growth is driven by advancements in technology, such as machine learning and AI, which enhance the capabilities of robotic systems. Manufacturing processes have evolved from traditional methods to highly automated setups that combine precision, speed, and adaptability. As robotic welding becomes more prevalent, it allows for seamless integration into production lines, enabling manufacturers to maintain high-quality standards while scaling operations effectively.

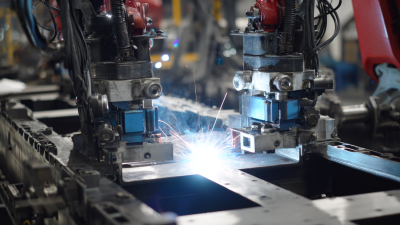

Robotic welding technology has revolutionized the manufacturing sector, providing numerous advantages that enhance productivity, safety, and quality. According to a report by the International Federation of Robotics, the global market for robotic welding systems is projected to grow at a CAGR of 9% from 2020 to 2024. This growth is driven by the increasing demand for automation and precision in industrial processes. By implementing robotic welding cells, manufacturers can achieve higher consistency in weld quality, reducing defects and rework costs.

Studies indicate that companies using robotic welding can experience a 50% reduction in welding defects compared to traditional methods.

Another significant advantage of robotic welding technology is its ability to increase overall efficiency. By replacing manual labor with automated systems, manufacturers can reduce cycle times and improve production throughput. A report by Deloitte noted that manufacturers utilizing robotic welding can improve their operational efficiency by up to 30%, allowing them to meet market demands more swiftly.

Furthermore, robotic systems often operate continuously without fatigue, leading to increased output and reduced downtime. The strategic implementation of robotic welding cells not only enhances productivity but also supports a safer work environment by minimizing human exposure to hazardous welding fumes and high-temperature processes.

Robotic welding cells are revolutionizing manufacturing processes across various industries. One noteworthy real-world application is in the automotive sector, where companies like Ford have integrated robotic welding to enhance efficiency and precision in production lines. By employing these automated systems, Ford has significantly reduced welding times and improved the quality of welds, leading to less rework and higher overall productivity. Additionally, the flexibility of robotic welding allows for quick adjustments to different vehicle models, enabling manufacturers to respond swiftly to market demands.

Another compelling case study can be found in the construction industry. Companies like Bechtel have utilized robotic welding cells to streamline the assembly of large structures, such as bridges and buildings. This technology not only accelerates the welding process but also ensures consistent quality across all weld joints, crucial in maintaining structural integrity. By leveraging robotic welding, Bechtel has seen a reduction in labor costs and an increase in safety due to decreased manual handling of hazardous welding tasks. These examples highlight the transformative impact of robotic welding cells on various manufacturing applications, showcasing their ability to enhance efficiency and quality across sectors.

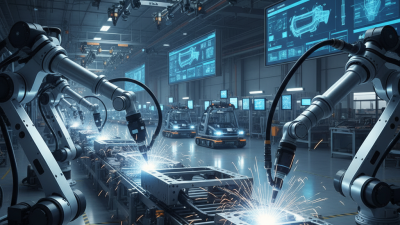

The future of robotic welding solutions is poised for significant advancements, particularly as market trends reflect a notable shift in manufacturing practices. As industries continue to embrace automation, the demand for robotic welding cells has surged, driven by their ability to enhance precision and efficiency while reducing labor costs. The welding consumables market is expanding, with products such as welding rods, solid wires, flux-cored wires, and welding fluxes gaining traction. This growth underscores the increasing adoption of diverse welding technologies, including arc welding, resistance welding, and laser welding.

In the context of emerging trends, the laser welding technology market is expected to witness substantial growth, with projections estimating its increase from approximately $747.8 million in 2024 to around $895 million by 2032, reflecting a compound annual growth rate of 2.3%. The recent World Intelligent Manufacturing Conference highlighted the importance of such innovations, showcasing over 300 industrial robots and reinforcing the global shift towards smart manufacturing solutions. As manufacturers look to integrate advanced welding technologies, the landscape of robotic welding cells will undoubtedly evolve, transforming the efficiency and quality of production processes in the coming years.

Contact Us

Pemamek Ltd