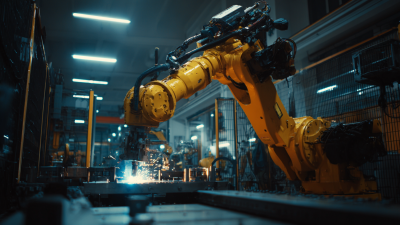

In the rapidly evolving landscape of the manufacturing industry, the integration of advanced technologies is crucial for enhancing productivity and efficiency. One such innovation making significant waves is the pipe welding robot, which has transformed traditional welding operations. By automating the welding process, these robots have been shown to increase production rates by an impressive 30%, allowing companies to meet rising demands while minimizing costs. This introduction of automation not only streamlines operations but also enhances precision and safety, addressing many challenges faced by manual welders. As industries strive to maintain competitive advantages in an increasingly globalized market, understanding the role of pipe welding robots in boosting operational efficiency becomes essential. In this exploration, we will delve into how these robotic solutions are reshaping the manufacturing sector, highlighting their impact on overall productivity and long-term sustainability.

In the manufacturing sector, the advent of pipe welding robotics is proving transformative, significantly enhancing productivity and efficiency. Recent investments, such as the $12 million by Reinke Manufacturing into robotic pipe cells, underscore the industry's shift towards advanced automation. Reports suggest that integrating robotics in pipe welding can lead to production boosts of up to 30%. These robots can operate at unprecedented speeds and possess enhanced awareness capabilities, allowing them to optimize workflows and minimize downtime during production.

The role of robotic systems in manufacturing is becoming increasingly critical as industries face rising labor shortages and demand for higher output. Companies are turning to intelligent automation to maintain competitiveness. For instance, new developments in autonomous high-precision welding systems have emerged, featuring cutting-edge AI technology that ensures consistency and quality in welds. By automating repetitive tasks, manufacturers not only increase efficiency but also reduce the potential for human error, paving the way for safer and more reliable production environments. The future of pipe welding and broader manufacturing processes is undoubtedly intertwined with the evolution of robotics.

In today's competitive manufacturing landscape, pipe welding robots are revolutionizing efficiency and reshaping production processes. One of the key advantages of employing these advanced machines is their ability to perform high-quality welds with precision and consistency. This not only reduces the chances of human error but also minimizes the need for rework, ultimately leading to significant savings in time and resources.

Another important benefit is the increase in output. By integrating pipe welding robots into manufacturing operations, companies can enhance their production rate by up to 30%. These robots can work continuously without fatigue, enabling plants to operate around the clock. This boost in productivity not only streamlines operations but also allows manufacturers to meet rising demands more effectively.

**Tips**: To get the most out of your investment in pipe welding robots, consider regular maintenance schedules to ensure optimal performance. Additionally, providing thorough training for your operators on robot programming and troubleshooting can help maximize the efficiency gains. Finally, integrating data analytics can provide insights into operational performance, helping to refine processes further.

The integration of pipe welding robots into manufacturing processes marks a significant advancement in operational efficiency. As manufacturers seek innovative solutions to enhance productivity, the implementation of these robotic systems offers a pathway to improved output and quality in pipe welding. Key steps for implementation include assessing the current workflow, identifying areas where robotics can streamline operations, and investing in training for personnel to work alongside these advanced machines. By effectively integrating pipe welding robots, manufacturers can achieve a substantial increase in production rates.

In addition to the immediate boost in productivity, automating welding processes also contributes to enhanced safety and precision. The collaboration between human workers and robots helps to mitigate risks associated with manual welding tasks while ensuring consistent quality. Furthermore, advances in AI and intelligent robotics can assist manufacturers in predictive maintenance, addressing potential equipment issues before they escalate. This holistic approach not only revolutionizes the welding process but also positions manufacturers to adapt to future technological developments in the industry.

In the manufacturing industry, the introduction of pipe welding robots has proven to significantly enhance productivity, achieving an impressive 30% boost in production. This quantifiable increase can be attributed to several key factors. Firstly, automation reduces the time spent on repetitive tasks, allowing for more efficiency in the workflow. Robots can operate continuously without the need for breaks, thereby maximizing output. Moreover, the accuracy of robotic welding minimizes errors and rework, further contributing to overall productivity gains.

Tips for companies considering the integration of pipe welding robots include starting with a thorough analysis of current production workflows to identify areas where automation can have the most impact. Additionally, investing in employee training for those who will manage and maintain the robots is essential to ensure a smooth transition and optimal utilization of the new technology. Lastly, setting clear metrics for productivity before and after implementation can help in quantifying improvements and justifying the investment in automation solutions.

| Parameter | Before Automation | After Automation | Percentage Improvement |

|---|---|---|---|

| Welding Speed (units/hour) | 50 | 65 | 30% |

| Defect Rate (%) | 8% | 5% | 37.5% |

| Production Downtime (hours/week) | 10 | 7 | 30% |

| Labor Costs ($/unit) | 20 | 14 | 30% |

Integrating robotics into welding processes can significantly enhance productivity, but it comes with its own set of challenges. One of the primary obstacles manufacturers face is ensuring seamless communication between robotic systems and existing machinery. To address this, companies should invest in advanced software solutions that facilitate real-time data exchange and synchronization, allowing robots to operate harmoniously within the production line.

Another critical aspect is the training and upskilling of the workforce. Workers must be equipped with the necessary knowledge to operate and maintain these sophisticated robotic systems effectively. Implementing comprehensive training programs, including hands-on workshops and simulations, can prepare employees to embrace this technology rather than fear it.

Furthermore, fostering a culture that prioritizes adaptability and continuous learning will ensure the smooth integration of robotics into the welding operations, ultimately leading to enhanced efficiency and productivity.

Contact Us

Pemamek Ltd