Mastering pipe fabrication is crucial for successful project management. Accurate fabrication techniques can directly influence project timelines and budgets. Skills in this area ensure that pipes are cut, shaped, and assembled efficiently, leading to fewer delays. However, mastering these techniques is not straightforward.

Many face challenges, such as miscalculations or equipment limitations. Understanding the intricacies of materials and designs is essential. Each project may require unique approaches, creating opportunities and obstacles. As pipe fabrication evolves, staying updated on techniques becomes vital. Seeking continuous improvement can foster better results.

Effective project management relies on seamless collaboration among team members. Communication is key in addressing issues that arise during fabrication. By refining these skills, project leaders can enhance workflow and minimize setbacks. Embracing imperfections can lead to innovation, ultimately driving project success.

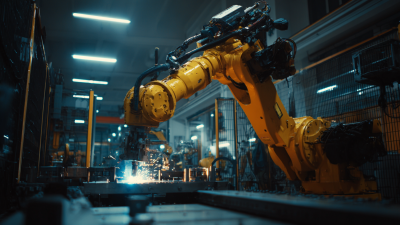

Pipe fabrication is a crucial process in various industries. Understanding the basics can significantly enhance project outcomes. Key techniques include cutting, bending, and welding pipes. Mastering these skills is essential, yet many overlook their importance.

Effective cutting requires precision. It’s easy to make mistakes if measurements aren’t exact. A slight error can lead to wasted material and time. Bending pipes also demands careful consideration. Too much pressure can cause kinks. This leads to costly repairs and delays.

Welding is the final step in fabrication. Proper techniques ensure strong joints, yet many struggle with consistency. Regular practice is necessary to achieve reliable results. Mistakes happen, and every error is a learning opportunity. Acknowledging these imperfections aids improvement. Understanding the basics of pipe fabrication is the foundation for successful project management.

When it comes to pipe fabrication, having the right tools and materials is crucial. A sturdy pipe cutter is essential for achieving precise cuts. It allows for clean edges, minimizing the risk of leaks. A reliable set of wrenches is also necessary to tighten joints effectively. However, improper use can lead to damage. Always check tools for wear and tear.

Materials play a vital role in pipe fabrication. Selecting the right type of pipe is important. PVC and metal pipes have different properties and uses. Be aware that not all materials are compatible. This can lead to failures in installations. It's wise to consult specifications before starting a project.

Additionally, fittings and joints are critical components. Investing in high-quality fittings reduces the chance of failures. However, it’s easy to underestimate their importance in a project. Rushing through the selection can lead to costly mistakes. Always take time to ensure each component is suitable for your specific needs. The details matter in creating a reliable pipeline system.

Pipe fabrication is an essential skill in various industries, particularly in construction and manufacturing. Understanding the different cutting and joining methods can greatly enhance project efficiency. For instance, a report by the Fabricators Association indicated that improper cutting techniques can increase material wastage by up to 15%. This statistic highlights the need for precision and mastery in pipe cutting.

When it comes to cutting pipes, there are several methods available. Each method has its own advantages. Mechanical saws are effective but can generate heat, potentially compromising pipe integrity. In contrast, plasma cutting yields clean edges but requires skilled technicians. Companies often face challenges when choosing the right method. Poor choices can lead to rework and significant delays.

Joining methods also vary greatly. Welding is a popular choice, providing strong bonds but requiring extensive training. On the other hand, soldering and adhesive bonding may offer convenience. However, these methods may not withstand high pressures. A detailed assessment of project requirements is crucial. A lack of proper planning can result in issues during the installation phase. Always consider the project specifications before choosing a joining technique.

| Technique | Description | Tools Required | Time Estimated | Difficulty Level |

|---|---|---|---|---|

| Pipe Cutting | The process of shortening or shaping pipes to required lengths and angles. | Pipe cutter, measuring tape, marker | 30 minutes | Medium |

| Pipe Joining | Techniques to connect two or more pipes securely. | Welding equipment, soldering iron, clamps | 1 hour | High |

| Bending | Shape pipes into curves or angles without kinking. | Pipe bender, heat source (if needed) | 45 minutes | Medium |

| Threading | Creating screw threads on the pipe ends for fittings. | Threading machine, pipe taps | 1.5 hours | High |

| Inspection | Verifying quality and integrity of joints and pipe. | Inspection tools, gauge | 30 minutes | Low |

Quality control is crucial in pipe fabrication processes. It ensures that each component meets the required specifications. By implementing robust quality control measures, teams can identify defects early and avoid costly rework. Regular inspections and testing can be effective. Workers should be trained to spot issues before they escalate.

Different stages of fabrication require specific quality checks. For instance, weld inspections can catch potential flaws in joints. Visual examinations can also reveal inconsistencies in material quality. However, even with these measures, errors can slip through. It’s important for teams to reflect on missed opportunities for improvement.

Communication is vital in maintaining quality. Teams must share information about process challenges and successes. Regular feedback sessions can help identify patterns in defects. This approach fosters a culture of continuous improvement. While seeking perfection, recognizing past mistakes plays a key role in enhancing future projects.

A well-planned project management strategy can significantly enhance the workflow of pipe fabrication. Effective scheduling is crucial. Use tools that allow real-time tracking of tasks. These tools can identify bottlenecks early. Adjustments can then be made promptly. Remember, communication is key. Regular check-ins with the team can clarify objectives and address concerns.

Consider the skill levels of your team members. Not everyone excels in every task. Assign roles based on strengths. This ensures everyone contributes their best effort. However, be prepared for mistakes. They are part of the learning process. Analyze failures when they occur. This reflection helps refine future strategies.

Tools and resources are essential, yet they should not dictate the workflow. Maintain flexibility in your planning. Unexpected issues will arise. When they do, adapting quickly can save valuable time. Encourage feedback from the team. Their insights can lead to improvements. Embrace the challenges along the way. They reveal areas where growth is possible.

Contact Us

Pemamek Ltd