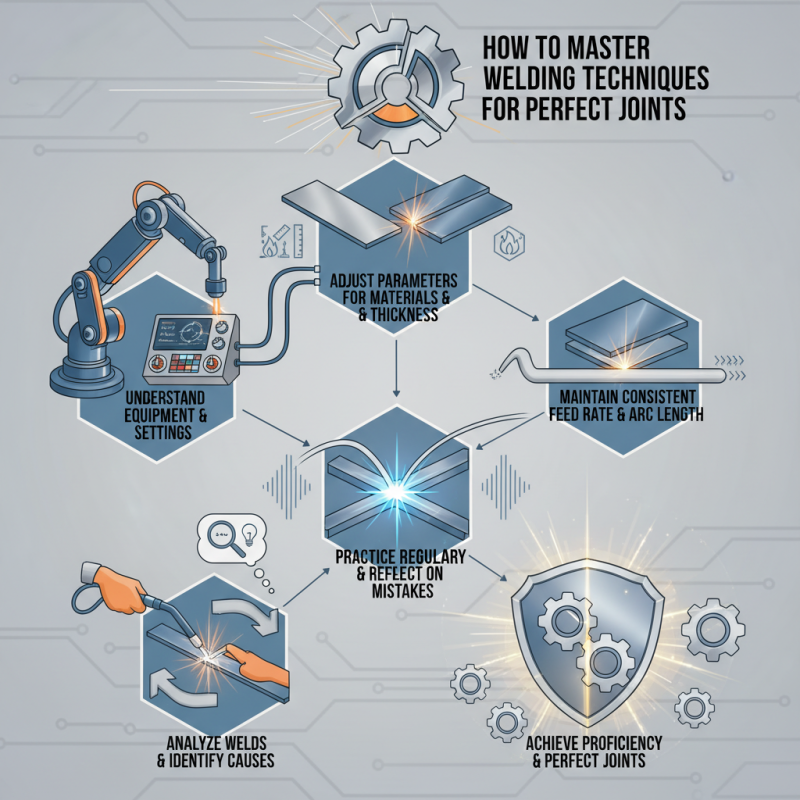

Automatic welding is a transformative technique in modern fabrication. It allows for precise joints and improved efficiency. However, mastering automatic welding requires more than just basic knowledge.

Begin by understanding the equipment and settings. Each machine varies, and incorrect parameters can lead to poor weld quality. Familiarity with the tools is essential, as is the skill to adjust settings based on materials and thickness. Errors in welding can arise from inconsistencies in feed rate and arc length. These issues may seem minor, but they significantly impact the final joint.

Practicing regularly is vital for improvement. It’s not unusual to face challenges while learning automatic welding. Reflections on mistakes will help enhance your skills. Analyze every weld, noting imperfections and their causes. Overcoming these hurdles will lead to better results and a deeper understanding of the craft. With dedication, anyone can achieve proficiency in automatic welding, ensuring perfect joints every time.

Automatic welding is a powerful technique used in various industries. Understanding its principles and techniques is essential for achieving perfect joints. This method relies on machines to ensure consistent weld quality. With precise control over speed, heat, and feed rate, welders can create strong connections. However, mastering automatic welding involves understanding the nuances of each project.

One of the key aspects is choosing the right parameters. Temperature and speed affect the weld quality directly. If the settings are off, it can lead to weak joints. Experimentation may reveal optimal settings for specific materials. Don't shy away from making adjustments during the process.

Here are some tips to enhance your automatic welding skills. First, regularly inspect your equipment. Poor maintenance can cause unexpected issues. Secondly, practice on scrap materials before actual projects. This approach allows you to fine-tune your technique. Lastly, always review and document your results. It helps in identifying patterns and improving over time. Welding is an art that requires constant learning and reflection.

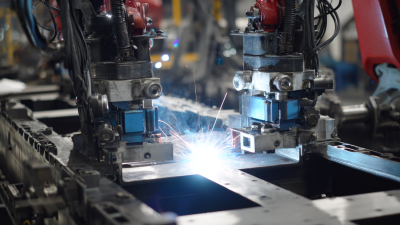

Automatic welding techniques are essential for achieving perfect joints in various applications. Among the most popular processes are MIG, TIG, and plasma welding. Each method has unique characteristics that make it suitable for specific tasks.

MIG welding uses a continuous wire feed and is ideal for beginners. The process is faster and allows for easy manipulation. However, it might produce a less aesthetic finish compared to TIG. TIG welding provides precise control with a tungsten electrode, making it suitable for thin materials. It requires steady hands and practice. It can be slow and may lead to overheating if not properly managed. Plasma welding is versatile and can work on both thick and thin materials. Yet, it demands more advanced skills and equipment.

**Tip:** Always check the settings before starting a weld. Incorrect parameters can ruin a project.

Reflecting on your results is crucial. Mistakes can happen, especially with different metals. Take time to analyze any issues. This reflection will lead to better future performances.

**Tip:** Keep a welding journal. Documenting your processes can help you remember what worked and what did not.

When diving into automatic welding, having the right equipment is crucial. A reliable welding machine is the core of any setup. Look for features like adjustable speed and power settings. A machine that seems perfect may not fit every task. Don't underestimate the importance of a good power source. It can make or break your project.

Protective gear is equally essential. Helmets with proper shading are vital to avoid eye damage. Gloves should be durable but flexible. They need to allow for dexterity while ensuring safety. Sometimes, a perfect fit is hard to find. You might need to try a few options before settling on the right one.

Cleaning tools are often overlooked. A clean joint is crucial for a strong bond. Wire brushes and grinders are necessary for surface preparation. However, remember that overdoing it can weaken the material. Finding the right balance requires practice. Explore different techniques and learn from mistakes. It’s part of the process. Each piece of equipment plays a significant role in achieving perfect joints.

Automatic welding techniques can greatly enhance the quality of joints. However, mastering these techniques requires an understanding of key parameters. Speed, voltage, and current play crucial roles in determining the weld's integrity.

Welding speed significantly affects heat input. A faster speed may lead to shallow penetration. This compromises joint strength. On the flip side, slowing down can cause excessive heat, which leads to warping. Striking a balance is essential. Finding the right speed requires practice and observation.

Voltage is another critical element. High voltage can produce a wider arc, which may not always benefit the weld. An arc that is too broad can lead to inconsistent penetration. Meanwhile, low voltage might narrow the arc, risking poor fusion. Adjusting voltage is often trial and error. Then there's the current, which dictates the heat supplied during welding. Too little current creates weak joints. Conversely, excessive current can burn through material.

Through experimentation and adjustment of these parameters, welders can achieve better results. Yet, it is important to acknowledge that perfection is rarely achieved on the first attempt. Continuous reflection on speed, voltage, and current will lead to improved skills and techniques.

Automatic welding presents several challenges that require attention. Common issues include inconsistent weld quality, insufficient penetration, and improper heat control. According to the American Welding Society, at least 30% of welds suffer from defects due to these factors. Such defects can lead to costly repairs and compromised safety.

To tackle these challenges, operators should focus on developing their skills. Regular training can significantly enhance proficiency in handling automated welding equipment. It’s also essential to maintain equipment meticulously. Regular inspections can prevent unexpected breakdowns, minimizing downtime.

Tips: Always use the right settings for your material. Adjust wire feed speed and voltage based on the thickness of the metal. Overheating can weaken joints. Additionally, seek feedback from colleagues or mentors. Their insights can highlight areas for improvement that you might overlook. Remember, practice doesn’t always make perfect; it makes progress. Embrace mistakes as opportunities to grow and refine your skills.

| Challenge | Description | Solutions | Best Practices |

|---|---|---|---|

| Inconsistent Weld Quality | Variability in weld appearance and strength. | Regular equipment calibration and maintenance. | Establish consistent parameters for welding. |

| Poor Wire Feed | Problems with wire feeding can cause defects. | Check for obstructions and ensure proper tension. | Use high-quality wire and correct feeder settings. |

| Inadequate Cooling | Leads to warping or cracking in welds. | Implement controlled cooling processes. | Monitor temperature and adjust cooling rates accordingly. |

| Contaminated Surfaces | Impurities can lead to weak joints. | Properly clean surfaces before welding. | Use appropriate cleaning methods like grinding or chemical cleaners. |

| Incorrect Welding Speed | Affects penetration and bead shape. | Adjust speed according to material and thickness. | Perform test welds to find optimal speed. |

Contact Us

Pemamek Ltd