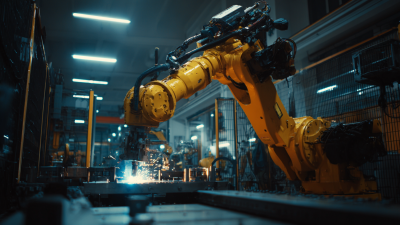

The efficiency and quality of pipe welding operations are critical factors in the industrial sector, particularly in industries such as oil and gas, shipbuilding, and construction. The use of pipe welding positioners has become increasingly prevalent as companies seek to enhance their operational effectiveness. According to a report by the American Welding Society, the adoption of welding positioners can reduce labor costs by up to 20% and improve weld quality and consistency by 15% to 30%. By maintaining optimal pipe alignment and allowing for automated adjustments, these devices minimize the risk of human error and ensure more precise welding results.

As industries continue to face escalating demands for productivity and high-quality outputs, understanding the impact of pipe welding positioners on operational efficiency becomes vital for manufacturers aiming to remain competitive. This guide aims to explore the various types of pipe welding positioners, their benefits, and best practices for implementation in industrial applications.

The selection of pipe welding positioners is pivotal for optimizing efficiency and maintaining high-quality standards in industrial applications. Factors influencing this selection include the type and size of pipes, the complexity of welds, and the environment in which the welding takes place. The recent patent granted to a prominent industrial company exemplifies the push for innovation in welding equipment, underlining the industry's emphasis on advanced technological solutions to meet evolving needs.

According to industry reports, the use of automated welding processes can enhance productivity by up to 40% and improve weld quality by reducing human error. Selecting the right welding positioner can significantly impact both aspects, allowing for precise control over the welding angle and speed.

**Tip:** When choosing a pipe welding positioner, consider the specific requirements of your project, such as the weight of the pipe and the need for rotation. Additionally, evaluate whether the positioner can accommodate future expansion as technology advances. Ensuring compatibility with existing equipment and adherence to safety standards is crucial in maximizing operational efficiency.

Pipe welding positioners have become indispensable tools in the industrial sector, particularly for enhancing both efficiency and quality in welding operations. According to a report by the American Welding Society, the implementation of such devices can boost productivity by up to 30%. This improvement is largely attributed to the positioners' ability to maintain optimal angles and orientations, reducing the physical strain on welders and minimizing the time spent on repositioning materials. Consequently, companies experience a quicker turnaround on projects, allowing for increased output without sacrificing quality.

Furthermore, the precision offered by welding positioners significantly enhances the quality of welds. A study by the International Institute of Welding indicates that using positioners can decrease defect rates by as much as 25%, thereby ensuring more consistent and reliable results in weld integrity. This reduction in defects not only lowers rework costs but also enhances the safety and durability of welded structures. By streamlining the welding process and ensuring high-quality outcomes, pipe welding positioners contribute to better resource allocation and reduced operational costs, making them an essential investment for companies aiming for long-term success in their projects.

In industrial welding applications, utilizing pipe welding positioners can significantly enhance both efficiency and quality. By correctly positioning the workpiece, these tools allow welders to maintain optimal angles, leading to cleaner, more precise welds. Moreover, effective use of positioners can minimize the time spent on adjustments, resulting in faster production cycles and reduced costs.

Tips: One effective technique for optimizing welding quality with positioners is to ensure that the workpiece is securely clamped. This prevents any movement during the welding process, which can lead to inconsistencies and defects. Additionally, operators should regularly calibrate positioners to maintain accuracy and ensure that they are working within the optimal range for the specific welding technique being employed.

Another strategy involves training personnel thoroughly in the operation of positioners. Skilled operators can recognize how to best adjust the settings depending on the specific materials and welding processes being used. Investing in operator education not only improves the quality of the welds produced but also empowers the team to troubleshoot issues and maintain the equipment effectively.

In industrial applications, pipe welding comes with its own set of challenges, particularly in terms of achieving consistent quality and maintaining operational efficiency. According to a report by the American Welding Society, around 30% of welding defects can be traced back to improper positioning of the pipe during the welding process. This not only leads to rework and increased labor costs but also affects the overall production timeline. Positioning errors can result in weak welds and increased stress concentrations, ultimately compromising the integrity of the welded joint.

Pipe welding positioners serve as a solution to these challenges by providing optimal alignment and stability during the welding process. By enabling welders to work from a more ergonomic and accessible position, these devices can significantly enhance weld quality. A study by Lincoln Electric shows that the use of positioners can reduce welding defects by up to 40%, resulting in lower rejection rates and improved productivity. Additionally, positioners can facilitate multi-pass welding techniques, allowing for more complex joint configurations to be completed efficiently and effectively. This addresses not only the technical concerns of weld quality but also the economic aspects of production, making pipe welding positioners an invaluable asset in modern industrial applications.

Maintaining pipe welding positioners is crucial for ensuring operational efficiency and the quality of welded joints in industrial applications. Regular maintenance not only prolongs the lifespan of the equipment but also enhances the quality of the welding processes. Key practices include routine inspections to check for wear and tear, lubrication of moving parts, and calibration of alignment features. By adhering to these practices, operators can prevent downtime caused by unexpected malfunctions and ensure consistent performance.

Tips for maintaining pipe welding positioners include:

In light of recent advancements such as electofusion technology, maintaining high welding standards is vital for durability and safety. Quality welding not only secures the integrity of products but also plays a significant role in the wider context of sustainability and environmental responsibility in infrastructure development.

Contact Us

Pemamek Ltd