In recent years, the field of welding technology has witnessed significant advancements, particularly through the evolution of welding manipulators.

According to the 2022 Global Welding Equipment Market Report, the welding manipulator segment is projected to grow at a CAGR of 5.6% over the next five years, driven by the increasing demand for automation in various industries, including automotive and construction.

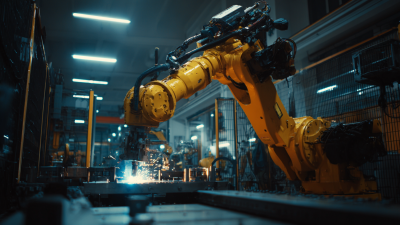

Welding manipulators enhance precision and efficiency, enabling operators to achieve optimal weld quality while minimizing human error. As the industry shifts towards Industry 4.0, the integration of digital technologies into welding manipulation systems is becoming imperative. The adoption of advanced robotics and real-time monitoring systems shows promise in revolutionizing traditional welding techniques.

This article explores the technological advancements and evolution of modern welding manipulators, highlighting their critical role in enhancing productivity and safety in welding operations.

Welding manipulators enhance precision and efficiency, enabling operators to achieve optimal weld quality while minimizing human error. As the industry shifts towards Industry 4.0, the integration of digital technologies into welding manipulation systems is becoming imperative. The adoption of advanced robotics and real-time monitoring systems shows promise in revolutionizing traditional welding techniques.

This article explores the technological advancements and evolution of modern welding manipulators, highlighting their critical role in enhancing productivity and safety in welding operations.

The history of welding manipulators traces back to the early 20th century, coinciding with the rise of industrialization and the demand for more efficient manufacturing processes. Initially, manual tools dominated the landscape, limiting precision and increasing the physical toll on workers. As industries expanded, so did the need for automation, leading to the development of the first semi-automated welding systems. These systems laid the groundwork for the more advanced manipulators we see today.

The evolution of welding manipulators has been marked by several significant milestones. In the 1950s and 1960s, advancements in electronics and control systems facilitated the introduction of motorized manipulators, allowing for greater accuracy and repeatability. This was a game changer, particularly in sectors such as automotive manufacturing, where consistent weld quality is paramount. With the introduction of computer-aided design (CAD) in the 1980s, manipulators became even more sophisticated, integrating complex algorithms that could adapt to various welding parameters in real-time. These technological advancements have not only enhanced operational efficiency but have also broadened the applications of welding manipulators across diverse industries.

| Milestone Year | Development | Key Feature | Impact on Industry |

|---|---|---|---|

| 1920 | First Mechanical Manipulators | Basic Movement Control | Increased safety in welding processes |

| 1950 | Introduction of Motorized Manipulators | Precision Control | Enhanced efficiency in large-scale manufacturing |

| 1975 | Robotic Welding Systems Developed | Automation Capability | Significantly reduced labor costs |

| 2000 | Smart Manipulators with Feedback Systems | Adaptive Control | Improved weld quality and precision |

| 2023 | AI Integration in Manipulators | Predictive Maintenance | Maximized uptime and resource efficiency |

Modern welding manipulators have greatly evolved due to advancements in technology that enhance efficiency, precision, and safety. Key technologies shaping this evolution include robotic automation, intelligent control systems, and advanced motion tracking. According to a recent market analysis by Research and Markets, the global industrial robotics market is expected to reach $78 billion by 2025, driven largely by the adoption of robotic welding solutions. This surge emphasizes the increasing reliance on machines that can operate with near-perfect repeatability, reducing defects and minimizing rework in the welding process.

Another significant advancement is the integration of artificial intelligence (AI) into welding manipulators. AI enhances the ability of automated systems to learn from data, allowing for real-time adjustments during the welding process. According to a study by PwC, 72% of manufacturers are investing in artificial intelligence to optimize their operations, underscoring the importance of smart technology in welding applications. Additionally, innovations in motion tracking, such as the use of laser and vision systems, allow for enhanced accuracy in joint positioning, which plays a critical role in achieving high-quality welds. As these technologies continue to develop, the realm of welding manipulators will see even more transformative changes, leading to improved productivity and operational excellence in the industry.

When selecting the right welding manipulator for your needs, several criteria should be carefully considered to ensure optimal efficiency and compatibility with your specific applications. The advancements in technology have transformed traditional welding processes, making it essential to evaluate features such as automation capabilities, precision control, and adaptability to various welding procedures. The recent achievements by students in advanced manufacturing highlight the importance of innovation in this field, particularly with the development of intelligent fuzzy-particle swarm optimization control systems for robotic manipulators.

These systems enable enhanced precision and responsiveness in automated welding applications, facilitating a seamless integration of robotic arms in industrial settings. When selecting a welding manipulator, it is crucial to assess factors such as payload capacity, flexibility in motion, and user-friendly interfaces. Furthermore, insights from recent research underscore the significance of servo control in improving actuator performance, leading to higher quality welds and increased productivity. These advancements not only streamline manufacturing processes but also position businesses to adapt to the ever-evolving demands of the industry.

The demand for efficiency and precision in welding operations has led to significant advancements in welding manipulators. Modern manipulators are equipped with sophisticated technologies that enhance their functionality, enabling operators to achieve precise welds with minimal effort. These advancements include automated controls, which allow for consistent welding parameters, and adaptive techniques that adjust settings in real-time according to the material and weld position. Such innovations reduce human error and improve overall productivity on the shop floor.

In addition to automation, the integration of advanced sensors plays a crucial role in enhancing welding operations. These sensors monitor variables such as temperature, speed, and weld quality, providing immediate feedback to operators. This real-time data allows for immediate adjustments, ensuring that each weld meets the required standards. Furthermore, the use of simulation software enables operators to plan and visualize welding sequences before actual implementation, drastically reducing setup times and material waste while increasing efficiency. By embracing these modern techniques, welding operations can not only improve their output but also ensure the highest quality in their products.

The future trends in welding manipulator technology are heavily influenced by advancements in automation and artificial intelligence. As industries seek to enhance productivity and precision, the integration of robotics into welding processes is becoming increasingly common. This shift towards automated solutions not only improves efficiency but also addresses the skilled labor shortage faced by many sectors, particularly in construction and automotive. The upcoming years are likely to see a rise in the use of collaborative robots, or cobots, which can work alongside human operators, making the welding process safer and more adaptable to various tasks.

Moreover, the evolution of welding techniques, such as laser welding, is anticipated to contribute significantly to the market growth. The laser welding technology market is on track for substantial expansion, with predictions suggesting an increase from $747.8 million in 2024 to $894.9 million by 2032. This growth reflects a broader trend towards utilizing advanced technologies to achieve higher precision and reduce operational costs. As manufacturers continue to invest in innovative welding solutions, the market for welding manipulators is expected to evolve, fostering new applications and enhancing the overall capabilities of welding operations across various industries.

Contact Us

Pemamek Ltd