Pipe fabrication is a critical process in various industries, encompassing everything from construction to manufacturing. As the demand for efficient and reliable piping systems grows, mastering the techniques of pipe fabrication becomes increasingly essential for professionals in the field. This article highlights the top 10 essential tips that can lead to successful pipe fabrication, ensuring that projects meet both quality standards and deadlines.

In today’s competitive market, improving pipe fabrication processes can save time and resources, ultimately contributing to overall project efficiency. Understanding the intricacies involved in pipe cutting, welding, assembly, and inspection can make a significant difference in the final product. This guide aims to provide valuable insights and practical strategies for fabricators, enabling them to hone their skills and optimize their workflow. By implementing these essential tips, individuals and teams can elevate their pipe fabrication capabilities, leading to greater success and satisfaction in their projects.

In the realm of pipe fabrication, understanding key terminology and concepts is crucial for achieving success. Among these fundamentals, the significance of pipe types—such as seamless, welded, and fabricated—cannot be overstated. Each type possesses unique attributes that influence their applications, tolerances, and ultimately the efficiency of the fabrication process. According to the “2022 Global Pipe Fabrication Report,” seamless pipes are preferred in industries requiring high pressure and durability, accounting for approximately 30% of the market share.

Tip: Always ensure thorough communication of specifications among your team to mitigate errors related to pipe types and materials. Clear documentation will help avoid costly reworks and delays, setting the foundation for a smooth operation.

Another vital concept is the importance of proper measurement techniques and tools. Accurate dimensions are fundamental to ensuring compatibility and maintaining the integrity of piping systems. Industry standards, such as ASME B31, emphasize that precise measurements can lead to a reduction in waste by up to 20%, significantly impacting project timelines and budgets.

Tip: Implement training sessions on measurement protocols for all fabrication team members. This proactive approach can enhance skills and foster a culture of precision, which is essential for high-quality output.

Understanding these foundational terms and practices not only increases efficiency but also elevates the overall quality of pipe fabrication projects, steering them towards successful outcomes.

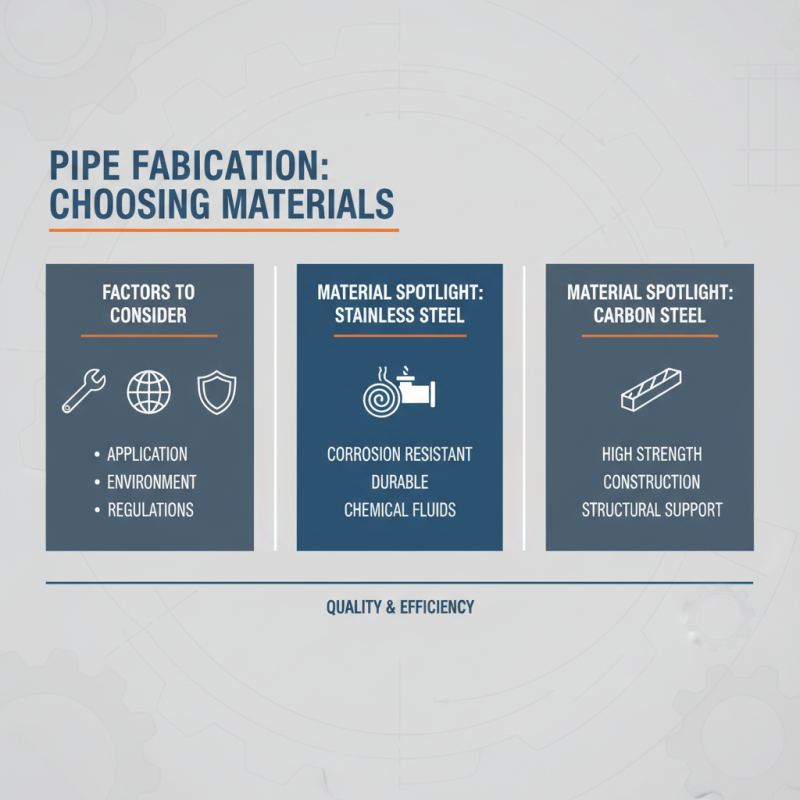

Choosing the right materials is crucial for effective pipe fabrication, influencing both the quality of the finished product and the efficiency of the fabrication process. When selecting materials, it's essential to consider factors such as the intended application, environmental conditions, and regulatory standards. For example, materials like stainless steel are often preferred for their corrosion resistance and durability, making them ideal for applications involving fluids with varying chemical properties. In contrast, carbon steel may be more suitable for construction purposes where strength is a priority.

Another important aspect is understanding the compatibility of the pipe materials with the fluids they will carry. This knowledge not only enhances operational efficiency but also prolongs the lifespan of the pipes. For instance, using specific alloys or coatings can mitigate issues related to corrosion or erosion, particularly in industries that deal with abrasive substances or extreme temperatures. By prioritizing the selection of appropriate materials based on performance specifications and environmental factors, fabricators can significantly improve the overall reliability and functionality of their piping systems.

When it comes to successful pipe fabrication, having the right tools and equipment is critical. Essential tools include pipe cutters, which allow for precise and clean cuts, ensuring the integrity of the piping system. Additionally, welding machines are fundamental for joining pipes securely. Depending on the materials used, various types of welding equipment such as MIG or TIG may be necessary to achieve strong, durable connections. Moreover, a reliable pipe bender can create the necessary angles and shapes without compromising the pipe’s structural integrity, making it a key addition to any fabrication shop.

Beyond these basics, proper measuring and alignment tools must not be overlooked. Tools like digital calipers and leveling lasers ensure accuracy in measurements, which is vital for achieving the desired fit and performance of the piping system. Adequate personal protective equipment is also essential; items such as gloves, helmets, and safety goggles protect fabricators from potential hazards. Investing in high-quality tools and equipment not only improves the efficiency of the fabrication process but also enhances the overall safety and quality of the final product.

Accurate measurement and cutting are fundamental aspects of successful pipe fabrication, impacting not just the quality of the final product but also the efficiency of the entire fabrication process. According to a report by the Fabricators & Manufacturers Association, up to 30% of fabrication waste can be attributed to inaccurate measurements and cuts. This statistic underscores the need for precision in the initial stages of pipe fabrication to minimize material waste and enhance overall productivity.

Employing advanced measurement technologies, such as laser scanning and digital calipers, can significantly improve accuracy. These methods allow for real-time data capture and analysis, making it easier to identify discrepancies before they result in flawed cuts. Furthermore, implementing cutting-edge CNC machines can ensure that pipe sections are cut with high precision, reducing the margin of error associated with manual cutting techniques. A study from the National Association of Manufacturers indicates that companies using automated cutting tools can increase productivity by up to 25%, highlighting the importance of investing in technology that supports accurate measurement and cutting practices.

To optimize performance, it is also essential to establish a consistent measurement protocol across all fabrication processes. Training staff on standardized measuring and cutting techniques can help eliminate variability and ensure that all workers follow best practices. The American Welding Society recommends regular calibration of measuring tools to maintain their accuracy, reinforcing the importance of an ongoing commitment to precision in pipe fabrication. By focusing on these techniques, fabricators can improve their workflows and deliver higher quality products with less waste and enhanced efficiency.

In the realm of pipe fabrication, implementing robust quality control practices is critical to ensure the integrity and reliability of the final product. According to a report by the American Welding Society, nearly 30% of pipe failures can be traced back to inadequate quality control during fabrication. This statistic underscores the necessity of establishing comprehensive quality assurance protocols that encompass every stage of the fabrication process, from material selection to final inspection.

A key aspect of effective quality control is the application of advanced monitoring techniques, such as non-destructive testing (NDT). Techniques like ultrasonic testing and radiographic inspection are essential in detecting internal flaws that may compromise the structural integrity of the pipes. The Boiler and Pressure Vessel Code emphasizes that rigorous adherence to these testing methods not only prevents costly failures but also enhances safety standards across the industry. Furthermore, regular audits and compliance checks are crucial, with reports indicating that companies with stringent quality control measures see an improvement in operational efficiency by up to 25%, thereby reducing rework and ensuring timely project delivery.

In addition to testing, maintaining well-documented fabrication processes and employee training programs is vital. The National Institute for Standards and Technology (NIST) indicates that organizations investing in employee education related to quality control see a 15% increase in overall productivity. By fostering a culture of quality and accountability, fabricators can not only meet industry standards but also exceed client expectations while significantly mitigating risks associated with pipe failures.

| Tip Number | Quality Control Practice | Description | Importance Level |

|---|---|---|---|

| 1 | Material Inspection | Ensure all materials conform to specifications before fabrication. | High |

| 2 | Welding Procedure Specification (WPS) | Use defined welding procedures to ensure consistency in weld quality. | High |

| 3 | Non-Destructive Testing (NDT) | Implement NDT methods to detect internal defects in welds. | High |

| 4 | Heat Treatment | Ensure proper heat treatment processes to enhance material properties. | Medium |

| 5 | Document Control | Maintain accurate and up-to-date documentation for traceability. | Medium |

| 6 | Training and Certification | Ensure all personnel are properly trained and certified for their tasks. | High |

| 7 | Process Monitoring | Continuously monitor fabrication processes to identify potential issues. | High |

| 8 | Final Inspection | Conduct a final inspection before shipment to ensure compliance with specs. | High |

| 9 | Use of Technology | Incorporate modern technology for improved accuracy and efficiency. | Medium |

| 10 | Feedback Loop | Establish a feedback loop for continuous improvement in processes. | Medium |

Contact Us

Pemamek Ltd