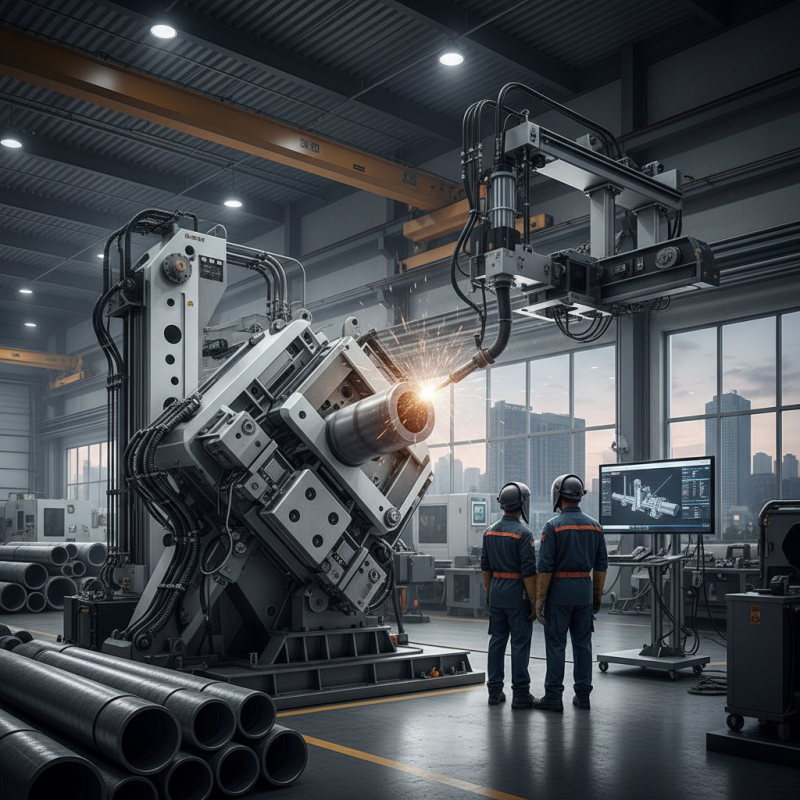

In the world of manufacturing and construction, achieving optimal performance in pipe welding and assembly operations is crucial for efficiency and quality control. A key component in this process is the pipe positioner, which enables precise positioning and alignment of pipes during welding, significantly enhancing productivity. According to a report by the American Welding Society, nearly 60% of welding defects can be attributed to improper pipe alignment, underscoring the importance of utilizing the right tools to mitigate such issues.

Selecting an appropriate pipe positioner is not merely about choosing a tool; it is about investing in a solution that can fundamentally transform workflow and output quality. With advancements in technology, modern pipe positioners offer a variety of capabilities, from adjustable angles to automated features that reduce manual labor. A comprehensive study by the International Institute of Welding indicates that organizations that optimize their equipment, including pipe positioners, can see a reduction in cycle time by up to 30%, illustrating the direct link between the right equipment choice and operational efficiency.

As professionals in the industry seek to enhance their operational effectiveness, understanding the nuances of pipe positioners—such as their load capacity, adjustability, and control features—becomes vital. This guide will provide essential tips for selecting the right pipe positioner, ensuring that your operations achieve the standard of excellence demanded in today’s competitive environment.

Pipe positioners play a crucial role in the welding industry by enhancing both the efficiency and quality of welds. They are specifically designed to hold pipes in various positions during the welding process, allowing welders to achieve optimal angles for both automated and manual welding. By accurately positioning the workpiece, these tools minimize the need for awkward body positions and reduce the risk of errors that can arise from poor visibility or difficult access to weld joints.

Understanding the functionality of pipe positioners involves recognizing their ability to rotate and tilt pipes, which significantly improves the welder's control and comfort. This function allows for consistent welds by keeping the welding arc steady and reducing the likelihood of defects caused by improper alignment.

Additionally, advanced pipe positioners offer features such as adjustable speeds and programmable settings, further enhancing their usability across different welding processes. Ultimately, selecting the right pipe positioner can greatly impact the overall performance, leading to higher productivity and superior finished products in welding applications.

When selecting a pipe positioner, it's essential to understand the different types available and their specific applications in various industries. Pipe positioners are classified into several categories, including manual, mechanical, and powered systems. Manual pipe positioners rely on operator input for adjustments, making them suitable for smaller projects where precision is needed but the workload is manageable. Mechanical positioners, often featuring adjustable arms or clamps, allow for some degree of automation, providing moderate ease of use and increased consistency. Powered positioners, on the other hand, are ideal for larger industrial applications, allowing for greater control and automation in positioning heavy pipes.

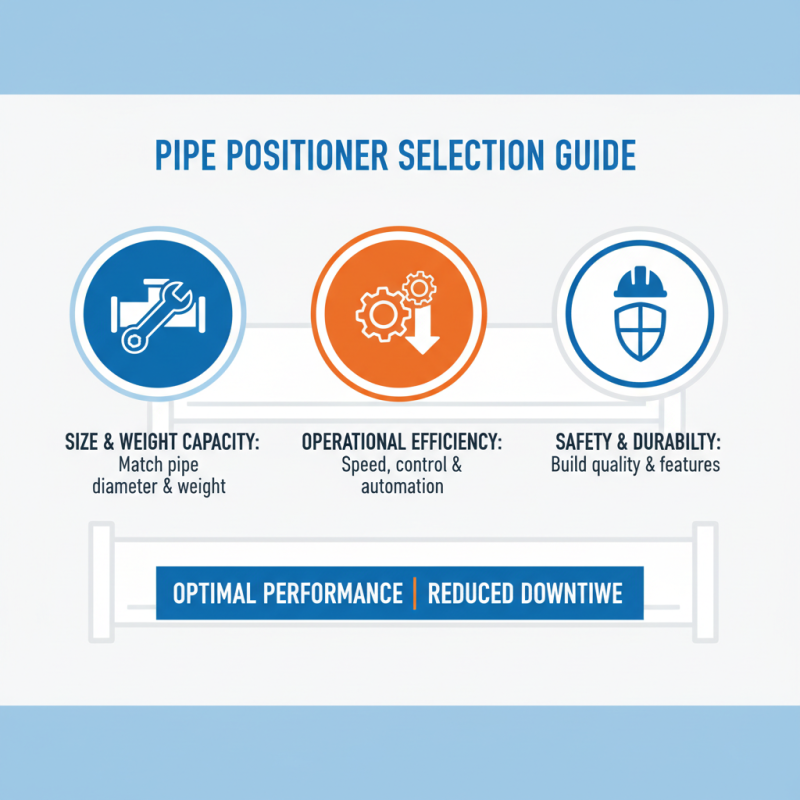

One tip to consider when choosing a pipe positioner is to assess the weight and size of the pipes you will be working with. Ensure that the positioner's capacity meets the demands of your projects. Additionally, examine the adjustability of the positioner; a more flexible design may better accommodate various pipe diameters and configurations, saving you time and effort on the job.

Another important aspect to evaluate is the environment in which the pipe positioner will be used. For example, if you're working in a confined space or a challenging environment, a compact and portable design could be beneficial. Always factor in the specific needs of your operations, as this insight will guide you in selecting the most suitable type of pipe positioner for optimal performance.

When selecting a pipe positioner, it's crucial to consider several key factors to ensure optimal performance and efficiency in your operations. First, assess the size and weight capacity of the positioner. It is important that the device can accommodate the specific diameter and weight of the pipes you'll be working with, as any discrepancies could lead to instability or operational challenges.

Another significant aspect to consider is the type of welding process you plan to use. Different positioners are designed to support various welding methods, such as TIG, MIG, or stick welding. Make sure to choose a positioner that aligns with your welding requirements to enhance productivity and achieve superior weld quality. Additionally, features like adjustable speed, swivel capabilities, and the ability to tilt or rotate can greatly affect your overall workflow.

Tips: Always evaluate the mobility of the pipe positioner. A unit that is easy to move can save time and effort when switching between tasks or repositioning for multiple welding joints. Look for positioners with ergonomic handles or wheels for increased maneuverability. Also, consider investing in a positioner with user-friendly controls, which can drastically reduce setup time and improve operator efficiency.

When selecting a pipe positioner, one of the most critical factors to consider is the load capacity and stability of the equipment. According to a report by the American Society of Mechanical Engineers (ASME), the efficiency of pipe welding operations can directly correlate to the positioner's ability to support different pipe sizes and weights. Positioners must be capable of handling the specific load characteristics without compromising stability. An ideal pipe positioner should accommodate the maximum weight of the pipes being used, and it is recommended to choose a positioner that offers a capacity margin of at least 25% above the expected load.

Stability is equally vital for achieving optimal performance in pipe positioning. The Center for Advanced Manufacturing's recent research indicates that inadequate stability can lead to increased downtime and decreased accuracy during welding, ultimately impacting overall productivity. Features such as adjustable bases and robust locking mechanisms can significantly enhance stability, ensuring consistent positioning. Additionally, utilizing models equipped with anti-slip surfaces and ergonomic designs can further minimize risks related to movement and vibration, which are crucial in maintaining high-quality welding outcomes. By prioritizing load capacity and stability, fabricators can enhance their operations, ensuring safety and efficiency throughout the welding process.

Maintenance is critical for enhancing the lifespan of pipe positioners, ensuring they operate at optimal performance levels. Regular inspections should be conducted to identify any wear and tear. Checking for loose bolts, leaks, or corrosion can prevent more extensive damage and downtime in the long run. It's essential to keep the equipment clean, as dirt and debris can hinder its functionality. A clean machine performs better and lasts longer.

One effective maintenance tip is to follow a scheduled lubrication routine. Ensuring that all moving parts are adequately lubricated reduces friction and wear, which significantly extends the lifespan of the components. Use the recommended lubricant, and make sure to check the levels regularly. Additionally, replacing worn-out parts promptly can prevent further damage to the machine, saving both time and money.

Implementing proper storage techniques also plays a vital role in maintaining pipe positioners. When not in use, they should be stored in a dry, temperature-controlled environment to protect them from extreme weather conditions. Utilizing protective covers can help shield the equipment from dust and moisture. Following these maintenance tips can greatly enhance the longevity and performance of your pipe positioners.

Contact Us

Pemamek Ltd