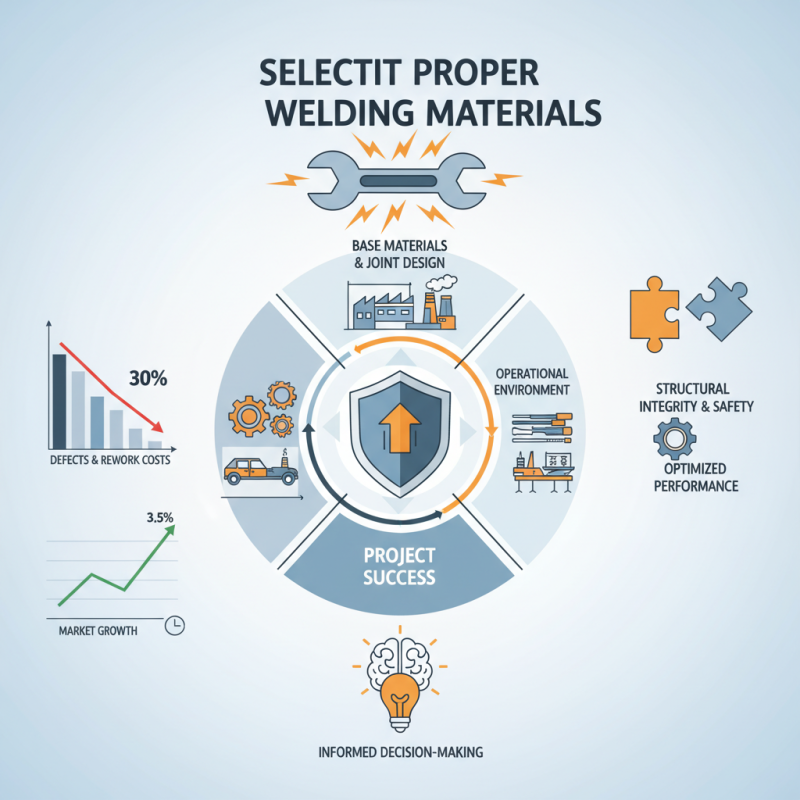

Choosing the right welding materials is a crucial decision that can significantly impact the quality, durability, and efficiency of any welding project. According to the American Welding Society, improper selection of materials can lead to an increase in defects, which may result in up to 30% of a project's total cost associated with rework and repairs. Furthermore, the 2021 Global Welding Consumables Market Report highlights that the market has seen a steady growth rate of around 3.5% annually, underscoring the rising importance of high-quality welding materials in the evolving landscape of manufacturing and construction industries.

The selection process for welding materials involves a thorough understanding of the base materials, joint design, and the specific environment in which the welded components will operate. Failure to adhere to these considerations can lead to catastrophic failures and safety hazards, particularly in critical sectors like aerospace and automotive, where stringent standards are mandated. As a result, investing in the appropriate welding materials not only enhances the structural integrity of the weld but also aligns with long-term operational goals, optimizing performance and reducing costs associated with material failure and maintenance.

In this context, the insights provided by industry experts and technical reports are invaluable. From the ongoing advancements in alloy compositions to the nuances of electrode selection, understanding the dynamics of welding materials is essential for professionals aiming to achieve excellence in their projects. The right choice can mean the difference between a successful outcome and a costly setback, ultimately reinforcing the vital role that informed decision-making plays in the welding industry.

Choosing the right welding materials is essential for the success of any construction project, as it directly influences the durability, strength, and safety of the structures being built. The selection process should consider factors such as the type of materials being joined, the environmental conditions, and the specific requirements of the project. By understanding the properties of various welding materials, engineers and project managers can make informed decisions that enhance the overall quality of the construction.

When selecting welding materials, it’s crucial to keep in mind the specific application. For instance, different metals require different types of filler materials, and the choice may vary based on whether the weld will be subjected to high stress or corrosive environments. Additionally, understanding the thermal expansion properties and the risk of distortion during welding can guide professionals in choosing the most compatible materials for their projects.

**Tips:** Always consult with experienced welders to gain insights into material compatibility. Regular training and staying updated on the latest welding technologies can also help improve material selection practices. Lastly, conducting thorough testing on welding samples can prevent costly mistakes and ensure that the chosen materials meet the project's requirements effectively.

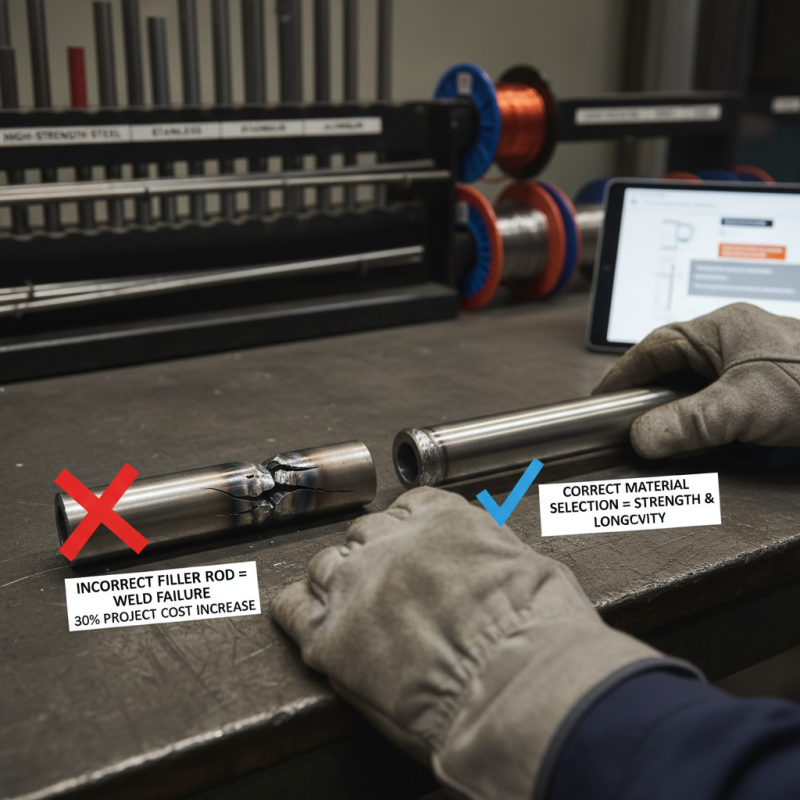

Selecting the appropriate welding materials is a critical aspect of any welding project, impacting both the structural integrity and longevity of the weld. One of the primary factors to consider is the type of base materials being joined. For instance, when welding high-strength steel, it's essential to choose filler materials that can withstand the specific stress and environmental conditions the structure will face. According to the American Welding Society, using the incorrect filler rod can lead to weld failure and increased repair costs, which can be up to 30% of the overall project budget.

Another crucial consideration is the welding process itself. Different processes, such as MIG, TIG, or stick welding, have unique requirements for materials. For instance, TIG welding often necessitates high-purity tungsten electrodes and specific filler wires tailored to the base material. A study by the National Institute of Standards and Technology emphasizes that suitable material selection can enhance efficiency, often reducing the time needed for repairs by as much as 40%. Additionally, environmental factors, such as exposure to corrosive elements or extreme temperatures, should influence material choice. Understanding these elements not only ensures compliance with industry standards but also greatly enhances the overall durability of the welds in various applications.

When it comes to welding, choosing the appropriate materials is fundamental to the success and durability of any project. Different types of welding materials serve unique purposes and are tailored for specific applications, affecting the final integrity of the welded joint. For instance, carbon steel is a popular choice in construction and fabrication due to its strength and versatility, making it ideal for structural components. Stainless steel, known for its corrosion resistance, is often employed in industries such as food processing and pharmaceuticals, where hygiene and longevity are paramount.

Another crucial category is aluminum welding materials, which are lightweight and possess excellent corrosion resistance. Aluminum is commonly used in aerospace and automotive applications, where reducing weight without sacrificing strength is essential. Additionally, filler metals, such as tungsten or electrode materials, play a significant role in providing the necessary properties for welds in more intricate and specialized work. By carefully selecting the appropriate welding materials based on the requirements of the project, professionals can ensure successful outcomes and extend the lifespan of the finished products.

| Welding Material | Common Applications | Advantages | Disadvantages |

|---|---|---|---|

| Mild Steel | Construction, Fabrication | Cost-effective, Easy to weld | Susceptible to corrosion |

| Stainless Steel | Food industry, Marine applications | Corrosion resistant, Durable | Higher cost, Difficult to weld |

| Aluminum | Aerospace, Automotive | Lightweight, Excellent corrosion resistance | Requires special techniques, Brittle |

| Copper | Electrical components, Plumbing | Good conductivity, Ductile | Costly, Can be challenging to weld |

| Nickel Alloys | Chemical processing, High-temperature environments | High strength at elevated temperatures, Corrosion resistance | Expensive, Requires skilled welders |

The impact of improper material choices in welding projects can be profound, leading to significant negative outcomes. According to a report by the American Welding Society, approximately 30% of all welding-related failures are attributed to incorrect material selection. This staggering figure underscores the importance of selecting the right materials to ensure structural integrity and longevity of the welds. Failure to choose appropriate filler metals, base materials, or protective coatings can result in issues such as reduced corrosion resistance, poor joint strength, and ultimately, costly repairs or replacements.

Furthermore, a study published in the Journal of Materials Engineering revealed that improper material choices not only affect the quality of the weld but also lead to increased operational costs. Projects that rely on inadequate materials can face a rise in maintenance expenses by as much as 50%, as frequent inspections and repairs become necessary due to compromised weld joints. Additionally, the safety implications of using the wrong materials can be severe, potentially endangering worker safety and leading to accidents that could have been avoided with rigorous material selection processes. Thus, investing time and resources in the correct welding materials is not just a best practice; it is essential for the success and safety of any welding project.

Choosing the right welding materials is a critical step that significantly impacts the quality and durability of any welding project. Best practices for sourcing quality materials can enhance performance, reduce costs, and ensure safety in welding operations. According to industry reports, approximately 30% of welding failures can be traced back to subpar materials, highlighting the importance of thoroughly evaluating suppliers and their product offerings.

To source quality welding materials, it's essential to establish a robust vetting process. Begin by researching potential suppliers through industry associations or by attending trade shows, which provide opportunities to meet manufacturers face-to-face and evaluate their materials directly. Additionally, pay close attention to certifications such as ISO 9001, which can indicate a commitment to quality management systems. Utilizing reports from recognized testing organizations can also guide you in selecting materials that meet specific project requirements.

**Tips:** Always request detailed technical data sheets from suppliers, as these documents provide crucial information regarding the mechanical properties and compliance standards of the materials. Moreover, consider conducting short trials or mock welds with sample materials before committing to larger orders. This practice allows you to assess the material’s performance and ensure it aligns with your project goals.

Contact Us

Pemamek Ltd