Choosing the right robotic welding classes can significantly impact your career in manufacturing. According to a report by the National Institute of Welding, the demand for skilled welders is projected to grow by 8% through 2029. This statistic highlights the importance of quality training in this field. Experts agree that investing in the right education is crucial for future success.

Dr. Emily Sanders, a leading authority in robotic welding, emphasizes, “The right training can set you apart in a competitive job market.” This statement underscores the value of specialized courses that focus on hands-on experience and advanced robotic technologies. Many programs promise comprehensive training, yet not all deliver on those promises. It’s essential to research and choose wisely.

In this evolving industry, taking shortcuts with education can lead to missed opportunities. Engaging in robotic welding without proper training may result in safety hazards and inefficiencies. Ensure that the classes you consider offer up-to-date technology and knowledgeable instructors who can guide you effectively. The right choice helps you remain relevant in an ever-changing landscape.

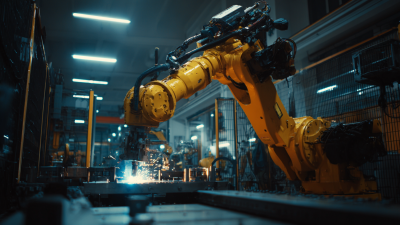

Robotic welding skills are increasingly vital in today’s manufacturing landscape. According to a report by the International Federation of Robotics, robotic welding accounts for over 30% of all industrial robots deployed globally. This percentage reflects a growing reliance on automation to boost efficiency and precision. Companies that invest in robotic welding technology experience a significant drop in production errors and a rise in output quality. This transition is not merely technical; it transforms workforce dynamics.

The demand for skilled technicians is on the rise. The Fabricators and Manufacturers Association predicts that by 2025, around 2.4 million manufacturing jobs may remain unfilled due to a skills gap. Many workers lack the necessary training in advanced robotic systems. Without proper education, companies can struggle to keep up with innovation. The need for well-trained professionals is crucial as industries shift towards automation.

Robotic welding requires both theoretical knowledge and hands-on practice. Classes should emphasize real-world applications. Students need to troubleshoot common issues and gain experience with different robotic systems. However, not all courses provide equal value. Some may not keep pace with evolving technologies. Therefore, careful selection of training programs becomes essential for future success.

When selecting robotic welding programs, accreditation is key. Accredited programs ensure quality education and industry standards. Look for institutions recognized by bodies in the welding or engineering fields. These programs often have better resources, experienced instructors, and updated technology.

Consider visiting a few campuses. Speak with instructors and current students. Does the facility have modern equipment? Can you see the classroom environment? These details matter. A hands-on approach will enrich your learning experience. Be wary of programs that lack transparency about their accreditation status.

Additionally, research job placement rates for graduates. Programs with successful placement history might indicate effective training. Connect with alumni who can share their experiences. Ultimately, choosing an accredited program can set a solid foundation for your career in robotic welding.

When evaluating robotic welding classes, curriculum is key. A strong program should cover essential topics. Look for classes that include basic welding principles and safety standards. Understanding these concepts is crucial. Without a solid grounding, students may struggle later.

Programming is another vital area. Courses should teach students how to program robotic welders. This hands-on experience is irreplaceable. Some students find programming to be challenging. It’s important to practice skills over and over. Real-world applications should be a focus, too.

Don’t overlook troubleshooting in robotic welding. Often, things don’t go as planned. Learning to identify and fix issues is necessary for success. Reflection on mistakes can lead to better strategies. Consider how class projects relate to actual industry scenarios. This helps bridge the gap between theory and practice.

Choosing the right instructor for robotic welding classes is crucial. The qualifications of instructors should include both educational background and hands-on experience. According to a recent industry report, about 73% of successful professionals value instructors with real-world experience. They believe that practical knowledge enhances classroom learning.

Instructors should also keep up to date with technological advancements. Welding technology evolves rapidly. About 61% of professionals find that innovative techniques improve their work efficiency. Instructors who regularly engage with industry developments can provide relevant insights. Students benefit from their experiences in actual welding environments, leading to better understanding.

When assessing instructors, consider their former roles. Have they worked in management positions? Have they been involved in significant projects? These experiences can be beneficial. Some instructors may have impressive degrees but lack field experience. A balance of academic knowledge and industry exposure is ideal. This combination fosters a more dynamic learning environment, equipping students with essential skills for their careers.

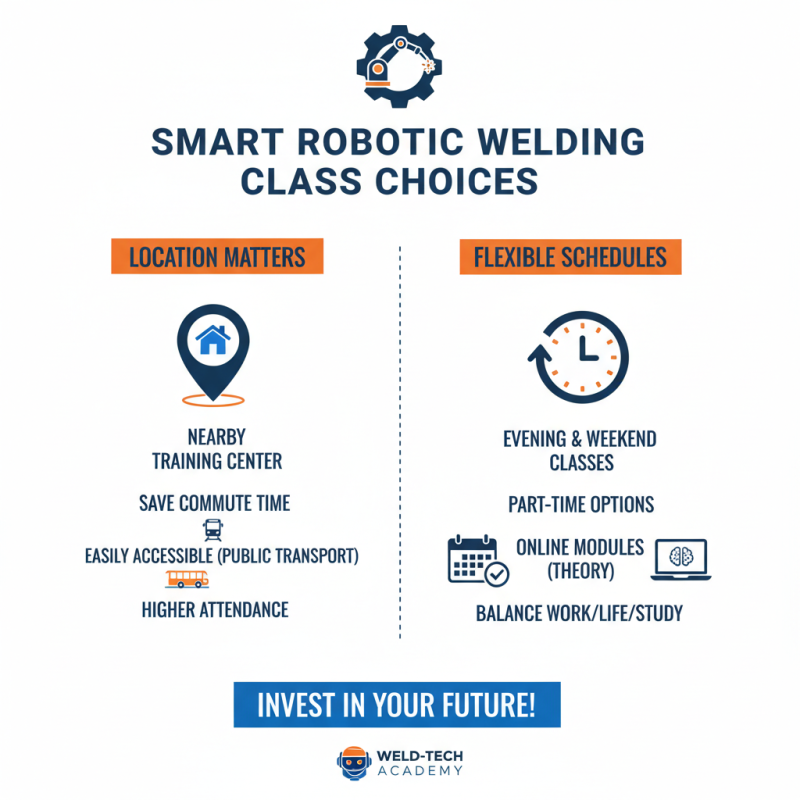

When selecting robotic welding classes, location and schedule flexibility are crucial. A nearby training center can save time and reduce commuting stress. Check if the school is easily reachable by public transport. Being close to home makes it more likely you will attend consistently. If you have a busy life, proximity matters.

Flexibility of schedules is equally important. Some programs offer evening or weekend classes, while others have full-time options. Think about your current commitments. Are you working full-time? Do you have family responsibilities? Choose a program that fits seamlessly into your life. If you can’t find classes that align with your routine, consider online options. They can provide the same quality without the need for constant travel.

Before deciding, visit the facilities if possible. Observe the classrooms and equipment. Are they well-maintained? Engage with instructors to gauge their expertise. Understanding their teaching style can give you insight into the learning experience. The right environment can make a significant difference, so take the time to reflect on what suits you best. A well-informed choice can affect your career path in profound ways.

Contact Us

Pemamek Ltd