Tank turning rolls are essential tools in industries that require the efficient rotation and positioning of large cylindrical objects. These ingenious devices are specifically designed to facilitate the handling of tanks, pipes, and other round items, allowing for a more streamlined workflow in fabrication and maintenance processes. The versatility of tank turning rolls makes them invaluable assets in operations ranging from welding and painting to inspecting and assembling.

In this article, we will explore the various features and benefits of tank turning rolls, highlighting how they enhance productivity and safety in work environments. We will delve into the different types available on the market, discussing their unique attributes and optimal uses. By understanding the mechanics and advantages of tank turning rolls, industry professionals can make informed decisions that lead to improved operational efficiency and reduced labor costs. Join us as we uncover the transformative impact of tank turning rolls on modern industrial practices.

Tank turning rolls are specialized devices designed to facilitate the maneuvering of heavy cylindrical objects, primarily in industrial and manufacturing settings. They operate on a principle of rotation that allows for the easy handling and positioning of tanks and large containers. The mechanism typically consists of a series of powered rollers that provide rotational movement, enabling operators to turn tanks effortlessly. This functionality is crucial in applications such as welding, painting, and inspection, where precise positioning is necessary to ensure quality and efficiency.

The action of tank turning rolls hinges on a few key components: the rollers, a drive mechanism, and control systems. The rollers are usually designed to grip the surface of the tank securely, allowing for uniform rotation without slipping. The drive mechanism, often powered by electric motors, provides the necessary torque to initiate and maintain movement. Additionally, many systems incorporate advanced control technology, allowing operators to adjust the speed and direction of rotation, ensuring optimal handling in various scenarios. This level of control is essential for increasing safety and reducing the risk of damage to both the equipment and the materials being handled.

This bar chart illustrates key features of tank turning rolls, highlighting their durability, load capacity, maneuverability, ease of use, and cost-effectiveness. These metrics are essential for evaluating the performance and selecting the right tank turning rolls for various applications.

Tank turning rolls are essential equipment in industrial environments, particularly for processes involving the fabrication and maintenance of large cylindrical structures. Understanding their key features is crucial for selecting the right model tailored to specific operational needs. One of the primary specifications to consider is the load capacity of the turning rolls, which dictates the maximum weight they can support while ensuring stability during rotation. High-quality turning rolls typically offer adjustable widths to accommodate various tank sizes, providing versatility and making them suitable for a range of applications.

Another significant aspect of tank turning rolls is the material quality used in their construction. Durable materials such as steel are favored for their strength and resistance to wear over time, ensuring longevity in demanding environments. Additionally, components like the wheel design play a critical role in performance, with rubber-coated wheels often preferred for their ability to grip surfaces and minimize slippage during operation. These features collectively enhance the safety and efficiency of tank turning processes, making it imperative for users to assess both the specifications and material quality when selecting the appropriate equipment for their projects.

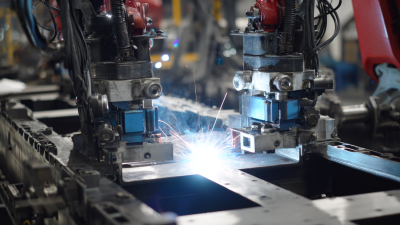

Tank turning rolls play a crucial role in various industrial applications, particularly in the fabrication and welding sectors. These specialized devices are designed to support and rotate cylindrical workpieces, such as tanks and pipes, providing significant advantages. One of the primary benefits of using tank turning rolls is the enhancement of safety and efficiency during welding processes. By properly aligning and rotating large materials, operators can achieve more accurate welds and reduce the risk of workplace accidents due to the stable positioning of heavy loads.

Another advantage is the increase in productivity. Tank turning rolls allow for continuous operation, as workers can weld around the entire circumference of a cylinder without the need for repositioning the item manually. This not only speeds up production times but also minimizes the labor required, leading to cost savings for businesses. Furthermore, these rolls can accommodate various sizes and weights, making them versatile tools in the workshop.

**Tips:** When selecting tank turning rolls, consider the weight capacity and size requirements of your specific applications. Always ensure the rolls are placed on a level surface to maximize stability and safety during operation. Regular maintenance and inspections of the equipment are also crucial to ensure longevity and optimal performance.

| Feature | Benefit | Industrial Uses |

|---|---|---|

| Adjustable Width | Versatility in handling different tank sizes | Oil and Gas Industry |

| Heavy-Duty Construction | Ensures durability and longevity | Chemical Processing |

| Precision Control | Improved accuracy in positioning tanks | Manufacturing Facilities |

| Easy Maneuverability | Reduces manual labor and increases safety | Construction Sites |

| Customizable Options | Can be tailored to specific operational needs | Water Treatment Facilities |

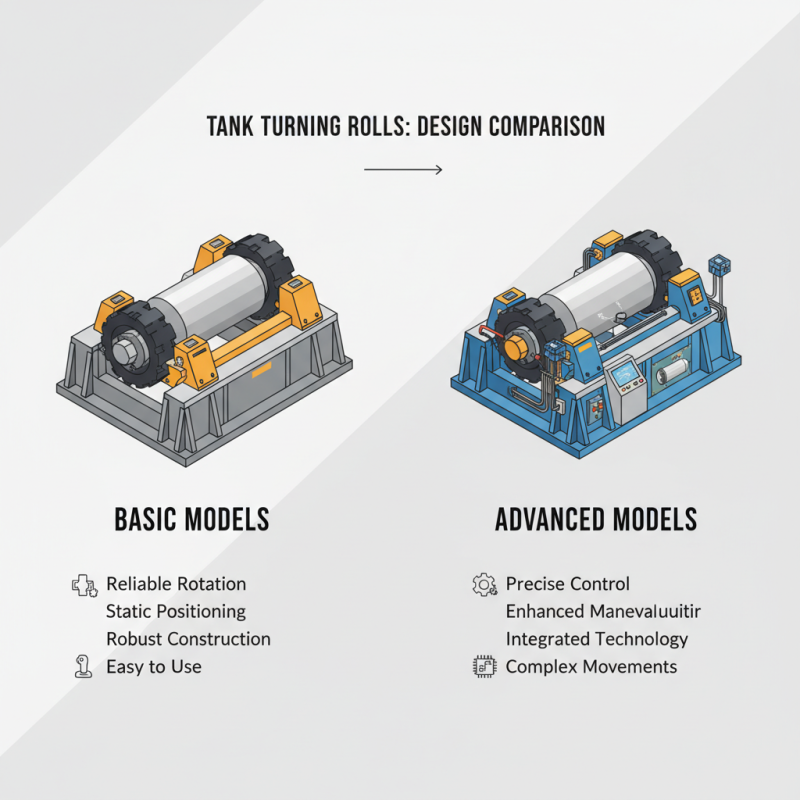

When evaluating different types of tank turning rolls, several key features emerge that distinguish each design's suitability for specific tasks. Basic models typically focus on straightforward design and functionality, offering reliable rotation for static tank positioning. These rolls often feature robust construction to support heavy loads while maintaining ease of use. On the other hand, advanced models integrate sophisticated technology, allowing for more precise control and maneuverability, which can be essential in high-stakes environments or when dealing with complex tank movements.

The benefits of using various tank turning rolls can vary significantly based on their construction and intended applications. For instance, heavy-duty rolls can facilitate efficient movement of large tanks, minimizing the risk of damage during operation. Conversely, lighter and more maneuverable options may be preferred in settings where space is limited or where tanks need frequent repositioning. Furthermore, comparative analysis suggests that some designs offer better longevity and lower maintenance costs, making them attractive for organizations focused on maximizing operational efficiency over time. Understanding these distinctions is crucial for businesses looking to enhance their tank handling processes and improve overall productivity.

Tank turning rolls have proven to be invaluable in various industries, particularly in manufacturing and construction. A case study published in "Industry Week" showcased a leading pipe manufacturing company that implemented tank turning rolls to enhance its production efficiency. Before the integration of these rolls, the company's fabrication process experienced significant delays, with an average product reorientation time of approximately 30 minutes per unit. Post-implementation, this time was reduced to just 10 minutes, resulting in a 67% improvement in workflow. The reduction not only elevated production capacity but also significantly lowered labor costs, demonstrating how tank turning rolls can optimize industrial operations.

Another noteworthy implementation can be observed in the shipbuilding industry, where a prominent shipyard adopted tank turning rolls for its assembly line. According to a report by the American Shipbuilding Association, the use of these rolls led to a 40% reduction in manual handling and enhanced safety conditions on the floor. Workers reported fewer instances of back injuries and strains, underscoring the ergonomic benefits of using tank turning rolls. Furthermore, the adoption resulted in a faster turnaround time for vessel construction, aligning with an industry trend where companies are pressured to deliver products more rapidly to remain competitive. These case studies illustrate the tangible benefits and diverse applications of tank turning rolls, making them an essential component in modern industrial operations.

Contact Us

Pemamek Ltd