In the world of metal fabrication, welding positioners play a crucial role. They enhance the efficiency and precision of welding tasks. Choosing the right welding positioner can significantly impact the quality of your work. With various options in 2026, it's important to understand their features.

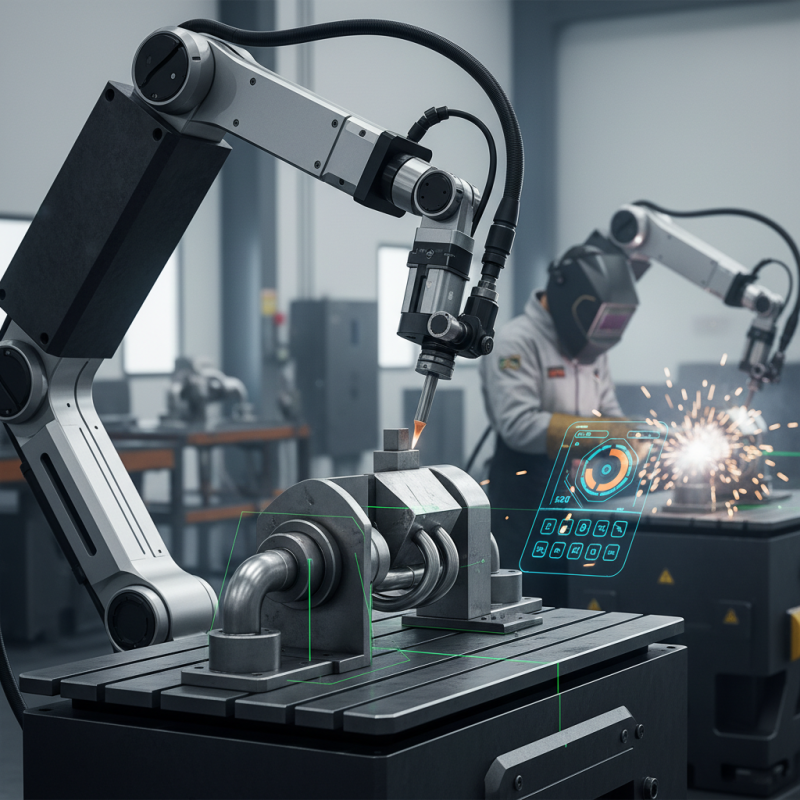

These machines help in aligning and rotating workpieces. This allows welders to achieve a better angle and access hard-to-reach areas. Many models now offer advanced controls and automation. However, not every welder needs the most expensive model. Learning to select the right welding positioners based on specific needs is essential.

Reflecting on personal experiences often reveals the gaps in understanding. A good positioner can prevent strain and fatigue during long shifts. Yet, some may overlook this investment. Efficiency should not come at the cost of quality. The right tools ultimately lead to better results in welding projects.

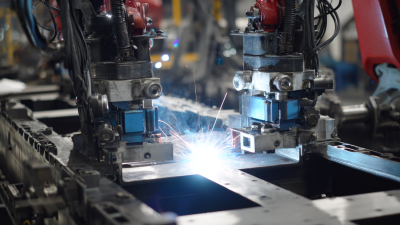

Welding positioners play a crucial role in enhancing the efficiency and precision of welding processes. These machines hold and maneuver workpieces, allowing welders to achieve optimal angles and access. Proper positioning reduces physical strain on welders and minimizes errors. It streamlines the welding operation, which can lead to better quality output.

Using a welding positioner can significantly impact productivity. However, choosing the right one is not always straightforward. Not all positioners fit every application perfectly, and mismatched equipment can lead to frustration. Welders may need to adjust their techniques, which can take time to master. This transition phase often reveals the importance of training and familiarity with the tools.

Moreover, improper setup can cause issues during the welding process. Positioners must be calibrated correctly; otherwise, they may not deliver the expected results. Sometimes, welders overlook small details, such as securing the workpiece correctly. It’s vital to reflect on these aspects to improve the overall welding experience. Efficient use of welding positioners ultimately elevates both safety and output quality.

When selecting a welding positioner, several key features can significantly enhance efficiency and precision. Load capacity is critical; most industrial models can handle loads up to 10,000 pounds. The right positioner must meet your operational needs. Having the correct axis adjustment is also essential. Many positioners offer both tilt and rotate functions. This allows operators to achieve the optimal welding angle, leading to improved weld quality.

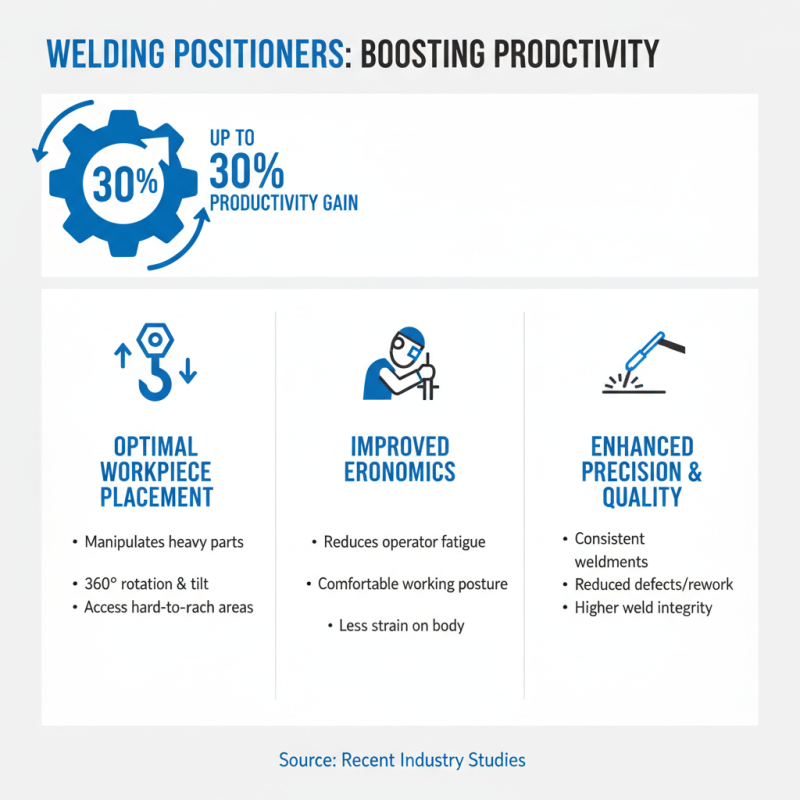

Another important consideration is the control system. Advanced positioners come with programmable controls. This feature allows for customization of welding paths. Reports indicate that automated systems can boost productivity by up to 30%. Manual systems may still be popular, but they often lack the consistency found in automated models. Additionally, consider the ease of setup and integration. An intuitive interface can reduce training time, but not all models deliver this.

Safety features should not be overlooked. Many modern positioners include automatic shutoff functions and overload sensors. These features can prevent accidents and equipment damage. Despite advancements, some users still face challenges when adapting to new technology. It's crucial to weigh the benefits of high-tech options against potential operational hurdles. Ultimately, the choice of a welding positioner should be informed by a thorough assessment of your specific requirements.

| Model | Load Capacity (lbs) | Rotation Speed (rpm) | Tilt Angle (degrees) | Features |

|---|---|---|---|---|

| Model A | 2000 | 0-15 | 0-360 | Adjustable height, Foot pedal control |

| Model B | 1500 | 0-10 | 0-180 | Digital control, Lightweight design |

| Model C | 3000 | 0-20 | 0-360 | Heavy-duty construction, Remote control |

| Model D | 2500 | 0-12 | 0-270 | Compact design, Versatile positioning |

| Model E | 1800 | 0-8 | 0-360 | Smart technology, Quick setup |

In the world of welding, choosing the right positioner can greatly impact efficiency and precision. In 2026, several options stand out due to their enhancements in design and functionality. These welding positioners offer unique features that cater to different types of welding jobs. Some are designed for heavy-duty projects, while others focus on precision tasks. Evaluating these features is essential for informed selection.

Tips: Consider the weight capacity of a positioner. If your projects are heavy, ensure the unit can handle the load. Look for adjustable height features. They provide flexibility for various tasks.

Not all positioners are perfect. Some may struggle with stability, especially on uneven surfaces. Others may require frequent calibrations, which can be time-consuming. User feedback is crucial. Seek opinions from peers who have used the models you’re considering. Real-world experiences can reveal insights that specs alone might not show.

Tips: Regular maintenance can prolong the life of your positioner. Check for wear and tear often. Also, understand how to operate it fully. Misuse can lead to accidents and inefficiency.

Welding positioners play a crucial role in enhancing efficiency and precision in welding operations. According to recent industry studies, implementing positioners can improve productivity by up to 30%. This improvement stems from the ability to manipulate workpieces into optimal positions. Proper positioning reduces operator fatigue and allows for a more ergonomic workflow.

Precision is another significant benefit. Welding positioners help maintain consistent angles and distances. Reports indicate that precise alignment can reduce defects by nearly 25%. Operators achieve better weld quality and fewer repairs. Yet, it is important to recognize that not all positioners are created equal. Some may lack necessary features like rotational speed control. Without these features, users might experience limitations in achieving the desired welds.

Moreover, initial investments in quality positioners can be steep. While the long-term benefits are evident, companies may hesitate. They must consider both the upfront costs and the potential for increased efficiency. This gap leads to reflection on whether the short-term savings outweigh the long-term advantages.

The welding industry is witnessing a significant transformation driven by advancements in positioner technology. Enhanced automation is at the forefront. Today’s positioners offer improved precision and control, enabling welders to achieve consistent results. Features like programmable rotation and tilt enhance workflow efficiency. Welders can now focus more on skill rather than manual settings.

Another notable trend is the integration of smart technology. Sensors and data analytics provide real-time feedback on welding processes. This insight helps in correcting errors promptly, thus minimizing waste. However, these technologies come with challenges. Not all operators are trained to utilize such advanced systems effectively. Sometimes, reliance on technology can overshadow basic skills.

Furthermore, the design of positioners is evolving. Lightweight materials and compact sizes enhance portability. This shift makes it easier to transport and set up equipment on various job sites. Yet, the balance between durability and weight remains a concern. Welders must navigate these trade-offs to find the right fit for their needs. As innovations continue, the call for user-friendly interfaces grows more crucial. Only then can the industry ensure that advancements don’t outpace the workforce’s ability to adapt.

Contact Us

Pemamek Ltd